Anilofos-pyrazosulfuron ethyl water surface diffusion agent and preparation method thereof

A water surface diffusion agent, the technology of pyrazosulfuron-methyl, applied in the field of pesticides, can solve the problem of uneven dispersion of pesticide active components in the diffusion radius, and achieve the effect of strong spontaneous diffusion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

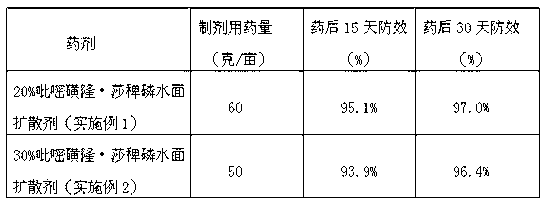

Examples

Embodiment 1

[0019] Formula: 2% pyrazosulfuron-methyl, 18% saprophos, 10% white carbon black, 8% peanut oil, 0.8% k-12, 3% polycarboxylate dispersant, 8% potassium chloride, 30 hollow glass beads %, the balance of kaolin.

[0020] First use white carbon black to fully absorb peanut oil, then add pyrazosulfuron-methyl, saponin, k-12, polycarboxylate dispersant, potassium chloride, hollow glass beads, kaolin, mix evenly, and after coarse crushing, airflow crushing , and then mixed for 30 minutes, the mixed material was put into a kneader and kneaded for 30 minutes, the kneaded material was granulated by a swirling fluidized granulator, dried and sieved, and 20% pyrazosulfone could be obtained after passing the test Long Shabai Phosphorus Surface Diffusion Agent.

Embodiment 2

[0022] Formula: 3% pyrazosulfuron-methyl, 27% saponin, 10% white carbon black, 8% white mineral oil, 2% opening powder, 5% naphthalenesulfonate formaldehyde condensate, 10% sodium sulfate, 5% starch , 40% sawdust powder, the balance of kaolin.

[0023] First use white carbon black to fully absorb white mineral oil, then add pyrazosulfuron-methyl, saponin, pull-off powder, naphthalenesulfonate formaldehyde condensate, sodium sulfate, starch, sawdust powder, kaolin, mix well, and coarsely pulverize After airflow pulverization, then mixed for 30 minutes, the mixed material was put into a kneader and kneaded for 30 minutes, the kneaded material was granulated by a swirling fluidized granulator, dried and sieved, and 30% Pyrazosulfuron-sulfuron-Sapylphos water surface dispersant.

Embodiment 3

[0025] Formula: 1% pyrazosulfuron-methyl, 9% saponin, 30% attapulgite, 8% soybean oil, 2% K-12, 5% polyoxyethylene polyoxypropylene ether block copolymer, calcium chloride 10%, starch 5%, sawdust powder 40%, kaolin balance.

[0026] First use attapulgite to fully absorb soybean oil, then add pyrazosulfuron-methyl, saponin, K-12, polyoxyethylene polyoxypropylene ether block copolymer, calcium chloride, starch, sawdust powder, kaolin, and mix Uniform, after coarse crushing, airflow crushing, and then mixing for 30 minutes, the mixed material is put into a kneader and kneaded for 30 minutes, the kneaded material is granulated by a swirling fluidized granulator, dried and sieved, and after passing the test That is to 10% pyrazosulfuron-methyl saponin water surface dispersant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com