Thermoelectric nuclear battery based on double-layer structure

A double-layer structure, nuclear battery technology, applied in the direction of electrical components, generators/motors, etc., can solve the problems of difficulty in laying temperature difference materials for thermonuclear batteries, low utilization rate of heat sources, etc., to reduce the risk of leakage, high utilization rate of heat sources, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

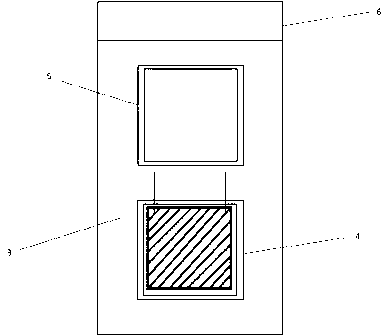

[0037] (1) Seal the radioactive isotope 238Pu directly into the radioactive source box. The radioactive source box is made of aluminum material and made into a hexahedron shape with a height of 100mm and a square bottom with a side length of 60mm;

[0038] (2) On each side of the four rings of the radioactive source box made of aluminum, two grooves with a side length of 30mm, a square shape, and a depth of 4mm are cut, arranged vertically and parallelly in the center along the height direction, and there are 8 grooves in total. groove;

[0039] (3) Put the formed square sheet-shaped temperature difference material in the excavated groove, the bottom surface of which is a square with a side length of 30mm and a thickness of 4mm, and connect each piece of temperature difference material in series;

[0040] (4) Put the radioactive source box into the casing. The casing is made of wood, hexahedron-shaped, 200mm high, and the bottom is a square with a side length of 100mm. the sq...

Embodiment 2

[0046] This embodiment is the same as Embodiment 1 except for the following differences.

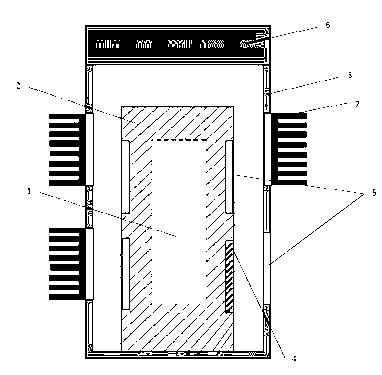

[0047] (1) The radioactive isotope 238Pu is directly sealed into the radioactive source box. The radioactive source box is made of copper material and made into a hexagonal prism with a height of 100mm and a regular hexagon with a side length of 46mm on the bottom surface;

[0048] (2) On each side of the six rings of the radioactive source box made of aluminum materials, two grooves with a side length of 30mm, a square shape, and a depth of 4mm are cut, arranged vertically and parallelly in the center along the height direction, and there are 12 grooves in total. groove;

[0049] (4) Put the radioactive source box into the casing. The casing is made of ceramic material, hexagonal column-shaped, 200mm high, the bottom surface is a regular hexagon with a side length of 54mm, and the inside is hollow and cylindrical, with a depth of 160mm and a diameter of 96mm;

[0050] (5) Dig two groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com