Battery power equalization circuit

A technology for balancing circuits and batteries, which is applied to battery circuit devices, circuit devices, current collectors, etc. It can solve the problems of difficult control of battery equalizers, slow equalization speed, and low equalization accuracy, achieving shortened equalization time, high equalization accuracy, and Improve the effect of balancing speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

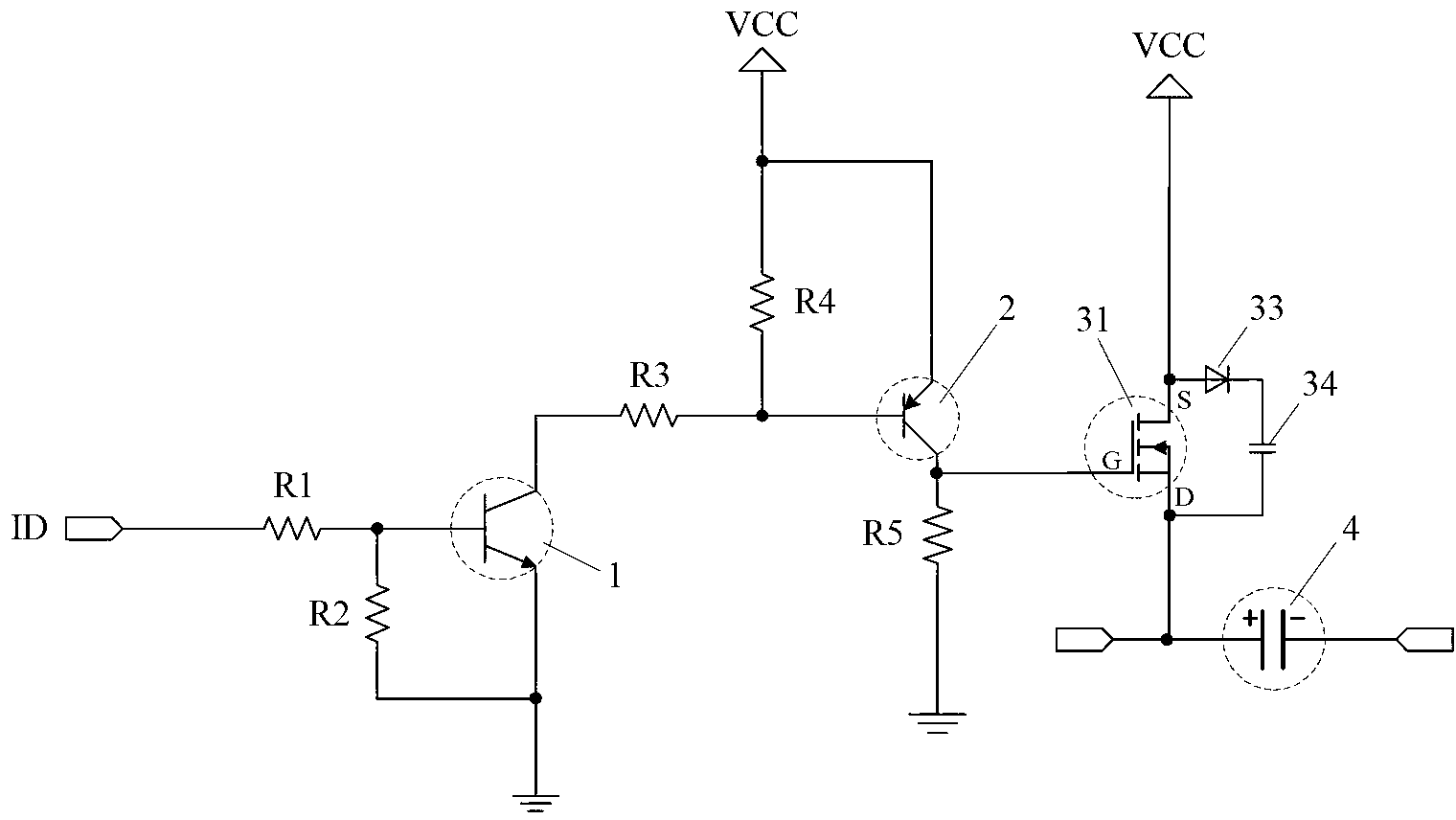

[0040] like figure 1 As shown, the present invention provides a battery power balance circuit, including: a battery pack, a voltage acquisition module, a switch circuit module, an energy transfer module and a main control circuit module.

[0041] The battery pack includes a plurality of series-connected battery sub-packs, each battery sub-pack includes a plurality of series-connected batteries.

[0042] The voltage acquisition module adopts a plurality of them, the number of which is equal to the total number of all batteries in the battery pack, and is used for real-time acquisition of voltage signals at both ends of each battery, and sending the voltage signals to the main control circuit module.

[0043] The switch circuit module includes a plurality of switches in the group and a plurality of driving circuits respectively used to drive the corresponding switches in the group, the number of the switches in the group is twice to four times the total number of all batteries i...

Embodiment 2

[0057] This embodiment will introduce in detail the circuit structure and connection relationship of the voltage acquisition module, the switch circuit module and the energy transfer module in the battery power balance circuit of the present invention in combination with a specific schematic diagram of the circuit connection relationship.

[0058] like figure 2 As shown, the voltage acquisition module includes a resistor R6, a resistor R7 and a capacitor C5; one end of the resistor R6 is connected to a battery, and the other end is connected to a resistor R7; one end of the resistor R7 is connected to the resistor R6 and the main control circuit respectively. The modules are connected, and the other end is grounded; the capacitor C5 is connected in parallel with both ends of the resistor R7. The voltage collection module is used to collect voltage signals at both ends of the battery in real time, and send the voltage signals to the main control circuit module ID.

[0059] Th...

Embodiment 3

[0064] This embodiment will use a specific example to describe in detail the circuit connection relationship between the battery, the switch circuit module and the energy transfer module in the battery power balance circuit, and the working principle of the battery power balance circuit.

[0065] like Figure 5 As shown, the battery power balance circuit includes 2 battery subgroups, respectively the first battery subgroup and the second battery subgroup, each battery subgroup includes 2 batteries, wherein the first battery subgroup includes batteries V1 and The battery V2, the second battery subgroup includes a battery V3 and a battery V4.

[0066] For the convenience of description, in this embodiment, the N-channel enhancement MOS transistor is represented by an NMOS transistor (in Figure 5It is only represented by N), and the P-channel enhancement MOS transistor is represented by a PMOS transistor (in Figure 5 Indicated by P only).

[0067] The switch circuit module i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com