Method for manufacturing WOLED (White Organic Light Emitting Diode), WOLED and display equipment

An organic and light-emitting unit technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., and can solve problems affecting the quality of display devices, light leakage from WOLED displays, and product color mixing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

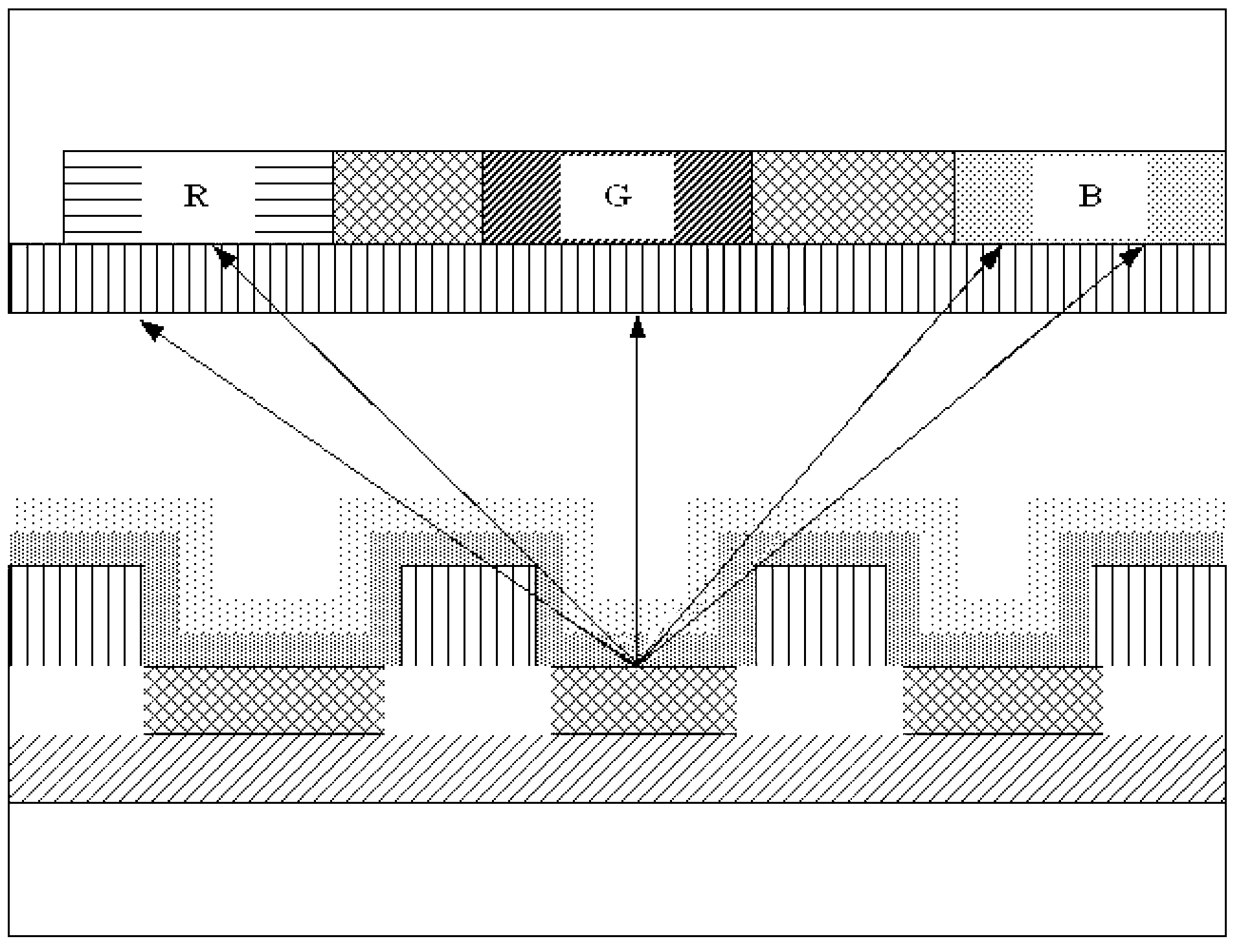

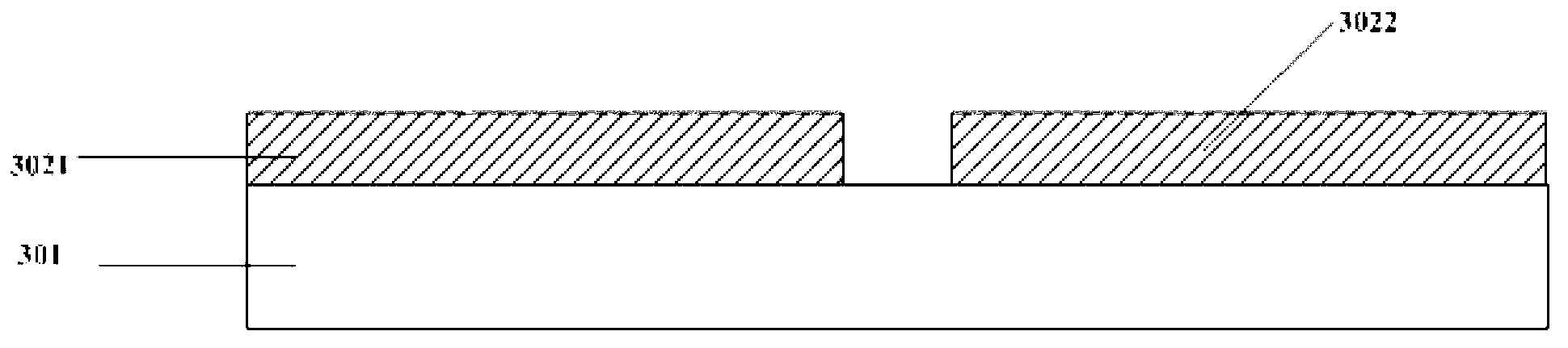

[0021] Aiming at the problem of light leakage in the WOLED display in the prior art, which makes the image display quality of the display device poor, the technical solution proposed here in the embodiment of the present invention deposits a reflective metal thin film on the array substrate, so that the array substrate and the color After the lamination process of the film substrate, even if there is a gap, the deposited reflective metal film can reflect back the light source emitted by the WOLED light-emitting layer, which better avoids the color mixing problem caused by the lateral light leakage phenomenon of the WOLED display in the prior art. The display quality of the WOLED display is better improved.

[0022] The main realization principles, specific implementation methods and corresponding beneficial effects of the technical solutions of the embodiments of the present invention will be described in detail below with reference to each accompanying drawing.

[0023] Embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com