Water injection mode of hub air tightness testing machine

An air-tightness, testing machine technology, applied in the use of liquid/vacuum for liquid-tightness measurement, by detecting the appearance of fluid at the leak point, etc., can solve the problem of water leakage, high requirements for water tank welding, and fatigue cracking of water tank welding. and other problems to achieve the effect of ensuring the line of sight, improving the test effect, and reducing the space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

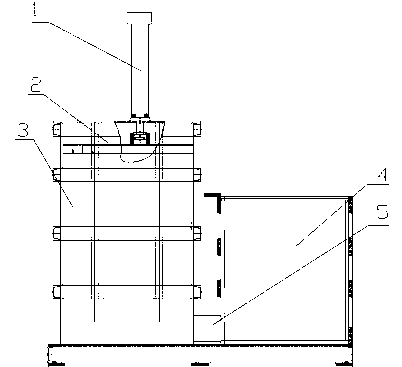

[0007] Depend on figure 1 As we know, the water injection method of the hub air tightness testing machine consists of the following components: air storage tank 1, water storage tank 2, inflation and pneumatic water system 3, return water deflation system 4, test water tank 5, liquid riser 6 and detection water level The system 7 is composed of a large amount of high-pressure gas stored in the gas storage tank 1. When the machine tool sends a signal to the pneumatic water inflation system 3; the solenoid valve in the system is opened to charge the high-pressure gas in the gas storage tank 1 into the water storage tank 2; Because the water in the water storage tank 2 is injected with gas, the pressurized water flows into the test tank 5 through the liquid riser 6; when the water level rises to the water level set by the detection water level system 7, the water level stops rising; the electromagnetic valve in the pneumatic water system 3 Close and maintain the water level; afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com