Rotation torque sensor supplying power by adoption of dynamic transformer in coupling mode

A torque sensor and transformer coupling technology, applied in torque measurement, instrumentation, power measurement, etc., can solve problems such as unreliable work, circuit failure, large friction loss between brushes and slip rings, etc., to expand the application range and reduce temperature drift The coefficient is small, the effect of solving the problem of anti-interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

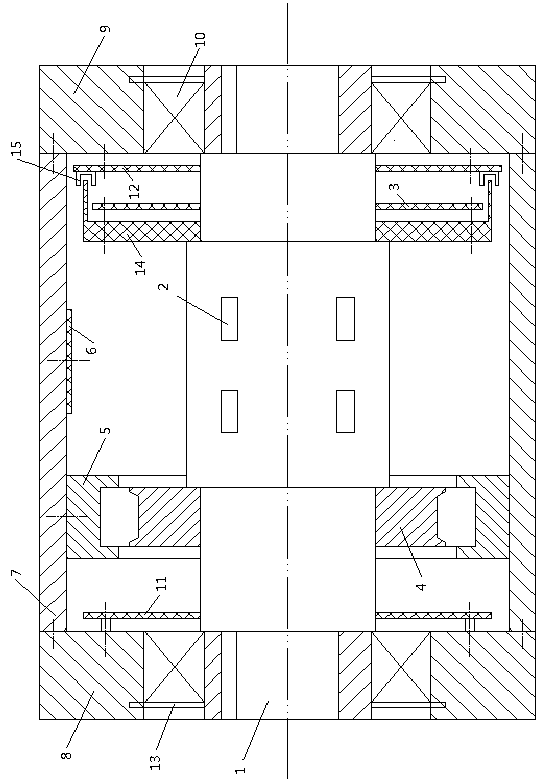

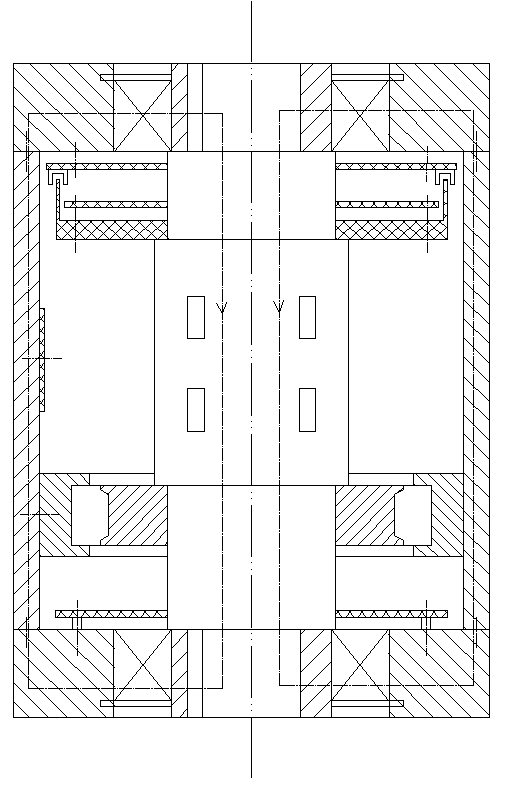

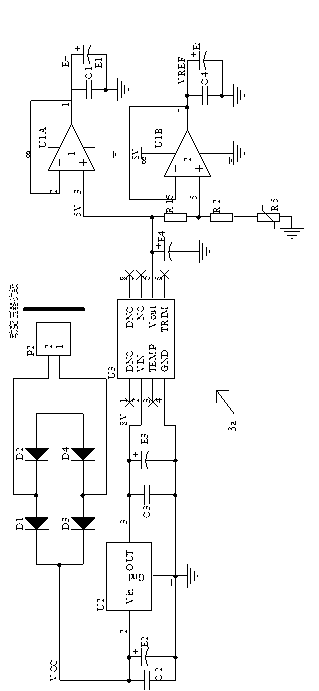

[0018] A rotary torque sensor that adopts a dynamic transformer coupling power supply, including an elastic rotary shaft 1, a strain gauge 2 is pasted on the shaft, a support plate 14 for installing a signal conditioning and infrared photoelectric emission circuit board 3, and a secondary coil 4 of a dynamic transformer are all fixed on the shaft body of the elastic rotating shaft 1, the F / V and V / I conversion circuit board 6, and the primary coil 5 of the dynamic transformer are all fixed on the shell of the shell 7, the primary coil 5 of the dynamic transformer and the dynamic The secondary coil 4 of the transformer is coupled, the two ends of the casing 7 are respectively fixed with end caps, the elastic rotating shaft 1 is installed on the end caps through the bearing 10, the primary oscillation driving circuit board 11 of the dynamic transformer, the infrared receiving and pulse shaping circuit board 12 are all Fixed on the end cover, a plurality of teeth are evenly spaced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com