Resistance heating furnace

A resistance heating and resistance technology, applied in electric furnace heating, furnace heating elements, furnaces, etc., can solve the problems of many heating elements, large maintenance costs, large heating elements, etc., to achieve simple maintenance process, improve economic benefits, and large heating power. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

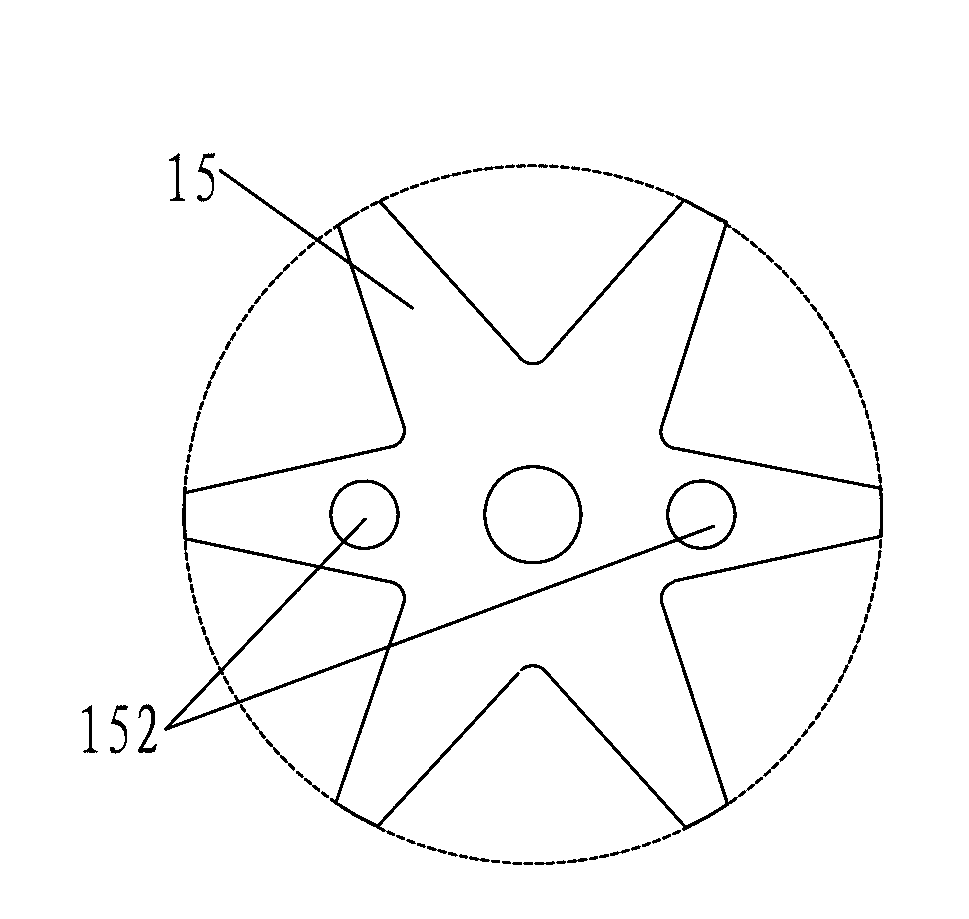

[0012] Such as figure 1 , 2 As shown, the resistance heating furnace of the present invention includes a furnace body 02 and a plurality of resistance heating elements 01, the furnace body 02 is provided with an insulating layer 22, the resistance heating element 01 includes a terminal post 11, and the terminal post 11 is covered with a rainproof cap 14, The protective casing 12, the resistance heating element 01 also includes a hoisting upper flange 13, a hoisting hanging wire insulating frame 15, a resistance wire 17, a hoisting rod 19, the hoisting upper flange 13 is welded to the lower end of the protective sleeve 12, and the hoisting hanging wire insulating frame 15 is columnar, such as image 3 As shown, two lifting rod holes 152 extending axially are arranged in it, and the two lifting rod holes 152 are symmetrical to each other along the axis of the lifting hanging wire insulation framework 15, and the two lifting rods 19 are respectively located in the two lifting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com