Cooling device of large-scale motor

A technology for cooling devices and large motors, which is applied in the direction of electromechanical devices, cooling/ventilation devices, electrical components, etc., and can solve problems such as difficult to equip air temperature adjustment devices, temperature rise of motor windings, and increased heat generation of motors, so as to save occupied space , obvious cooling effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

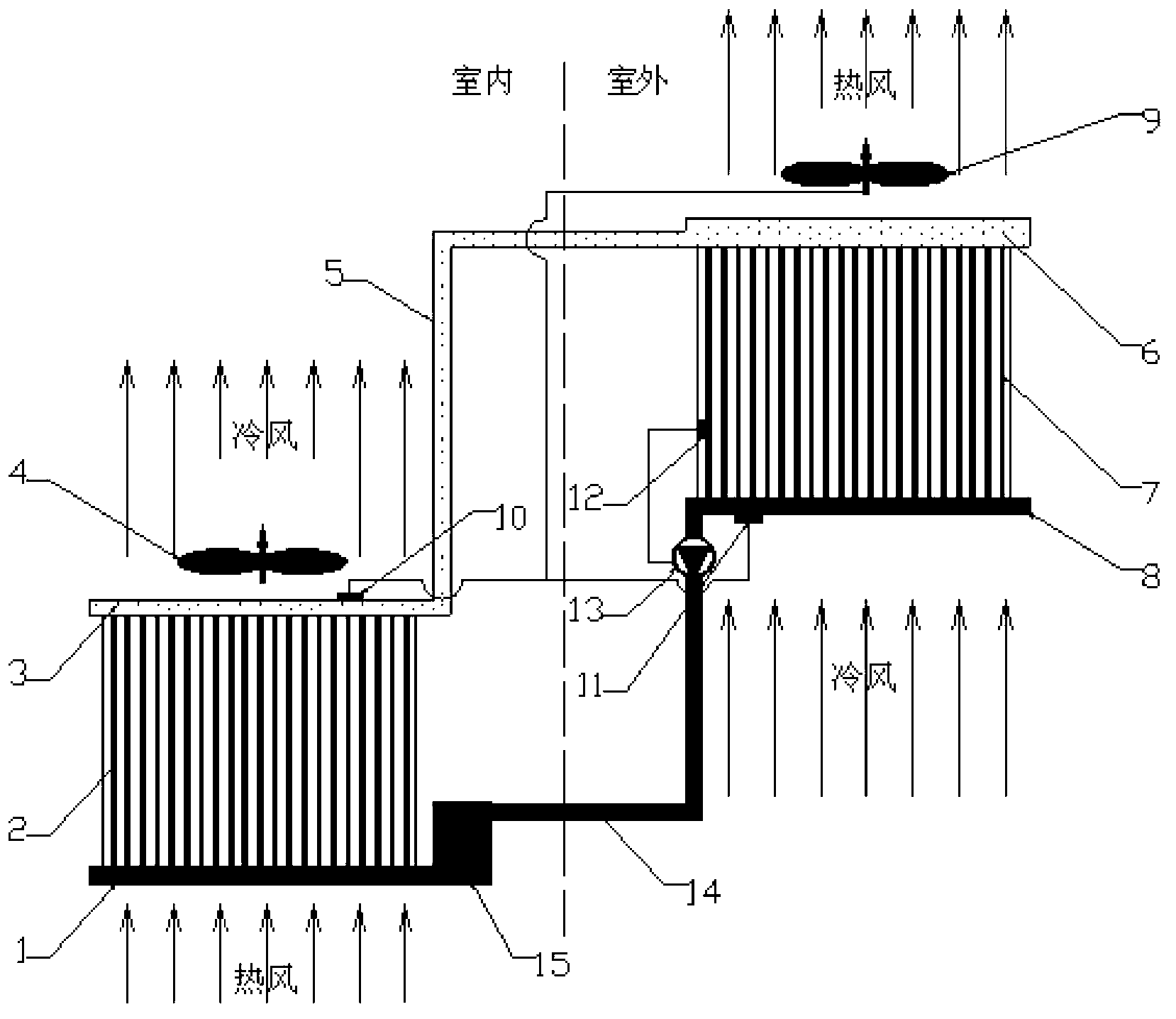

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] see figure 1 , figure 2 The cooling device for a large motor shown includes an evaporation mechanism, a condensation mechanism and a temperature sensor;

[0019] The evaporation mechanism is set at the fan inlet of the large indoor motor 4. The evaporation mechanism includes the evaporator heat pipe group 2. The upper end of the evaporator heat pipe group 2 is connected with the evaporator gas collection pipe 3, and the lower end of the evaporator heat pipe group 2 is separated from the evaporator. Tube 1 is connected;

[0020] The condensing mechanism is located outdoors, and the condensing mechanism includes a condenser heat pipe group 7, the upper end of the condenser heat pipe group 7 communicates with the condenser gas distribution pipe 6, the lower end of the condenser heat pipe group 7 communicates with the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com