An industrial gas data acquisition and monitoring device

A technology of data acquisition and monitoring device, applied in gas/liquid distribution and storage, pipeline system, mechanical equipment, etc., can solve the problem that gas data acquisition is not easy to lay a wired communication network, the user points of gas pipe network are scattered widely, and the judgment of dispatchers is affected. and other problems, to achieve the effect of good monitoring and management, reasonable structure, and ensuring completeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

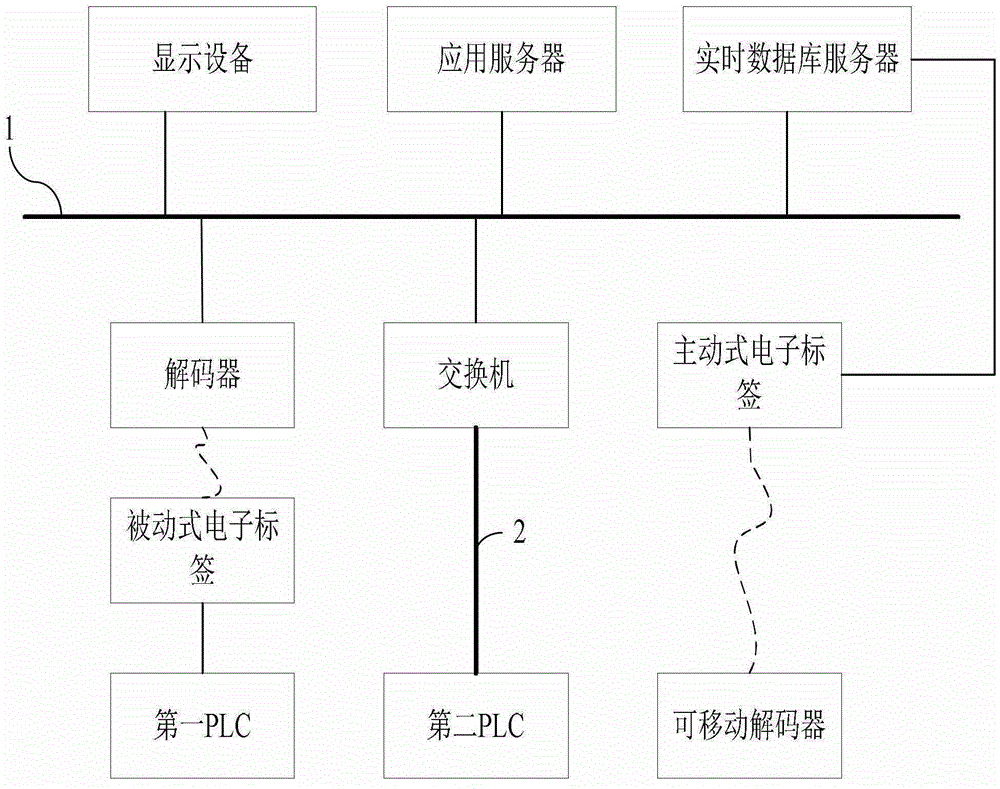

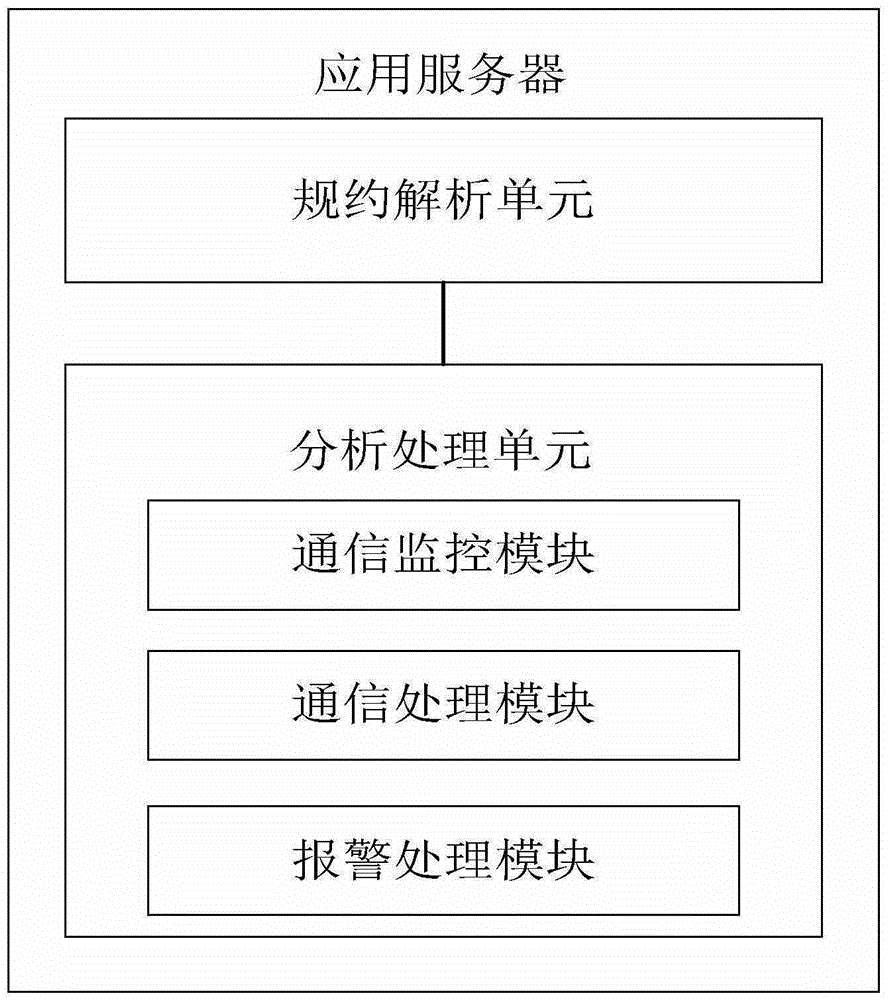

[0014] see figure 1 and figure 2 , an embodiment of the present invention provides an industrial gas data collection and monitoring device, including a first data collection system, a second data collection system, a data transmission network 1, an application server, a real-time database server, a first information collection device, a second Information collection device, active electronic label, mobile reader and display device. The first data acquisition system, the second data acquisition system, the application server, the real-time database server and the display device are respectively connected to the data transmission network 1 . The active electronic tag is connected with the real-time database server. The following further introduces the structure of the industrial gas collection and monitoring device provided by the embodiment of the present invention:

[0015] see figure 1 , the first data collection system includes: a first PLC, a first information collecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com