Method for preparing carbon-coated lithium iron phosphate from basic lithium iron phosphate

A technology for carbon-coated lithium iron phosphate and lithium iron phosphate is applied in the field of preparation of lithium iron phosphate and basic lithium iron phosphate to prepare carbon-coated lithium iron phosphate, which can solve problems such as undisclosed specific methods and achieve stable product performance. , The process is simple and the controllability is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

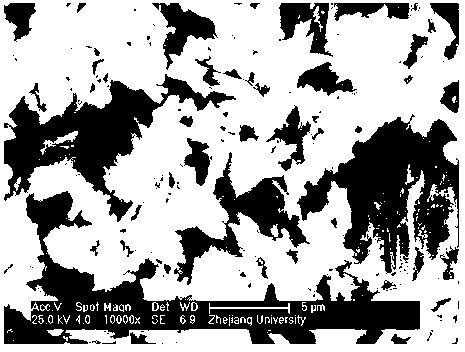

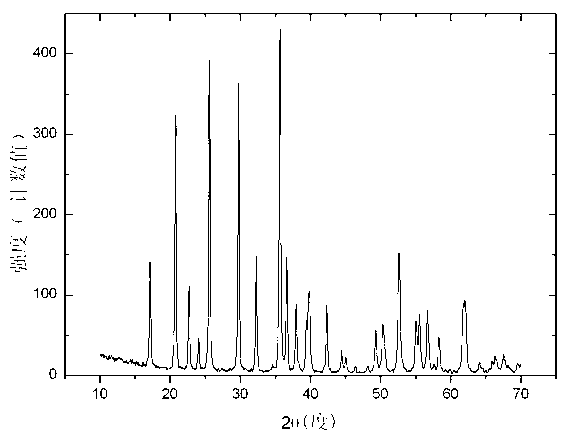

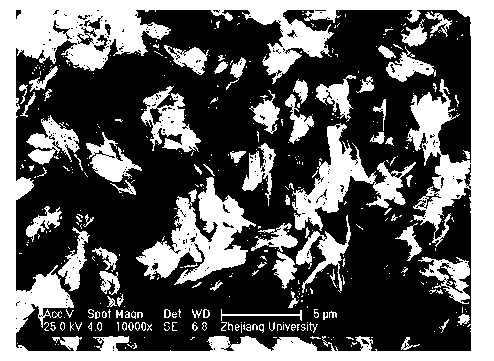

[0059] 1mol iron phosphate FePO 4 , 1mol lithium hydroxide LiOH and 4L deionized water were put into a ball mill and milled for 1 hour to obtain a mixture; then the mixture was added to the reaction kettle, reacted at 120°C for 32 hours, filtered, and dried to obtain the chemical formula LiFePO 4 (OH) basic lithium iron phosphate.

Embodiment 2

[0061] 1mol iron phosphate FePO 4 , 1.02mol lithium hydroxide LiOH and 4.5L deionized water were put into a ball mill and milled for 2 hours to obtain a mixture; then the mixture was added to the reactor, reacted at 200°C for 20 hours, filtered, and dried to obtain the chemical formula: LiFePO 4 (OH) basic lithium iron phosphate.

Embodiment 3

[0063] 1mol iron phosphate FePO 4 , 1.05mol lithium hydroxide LiOH and 5L deionized water were put into a ball mill and milled for 3 hours to obtain a mixture; then the mixture was added to the reactor, reacted at 250°C for 6 hours, filtered, and dried to obtain the chemical formula LiFePO 4 (OH) basic lithium iron phosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com