Perforating machine for refrigerated berries and production process of dried berries

A technology for piercing machines and berries, which is applied in the field of fruit processing methods and equipment, and can solve the problems of unsuitable small berry piercing holes, automatic falling off, irregular fruit shape, peel rupture, etc., and achieves simple structure, strong applicability, and economical labor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

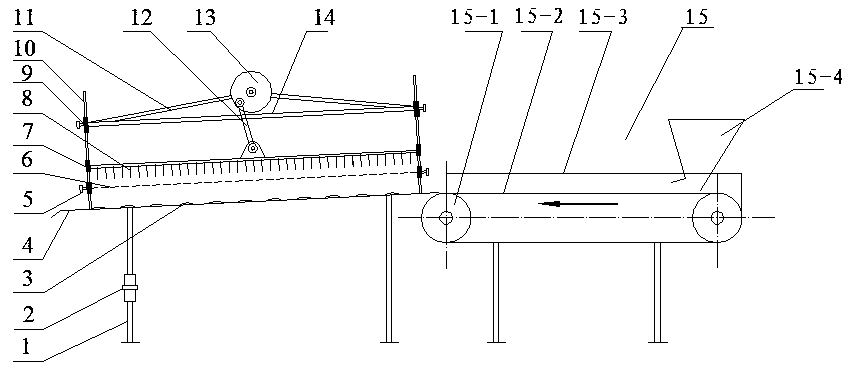

[0019] See figure 1 , 2 , 4, the frozen berry piercing machine is provided with a conveyor 15, and the conveyor 15 is provided with a pulley 15-1 driven by power, and the conveyor belt 15-2 is assembled on the pulley 15-1, and both sides are provided with side plates 15-3, and its front end A hopper 15-4 is arranged at the top;

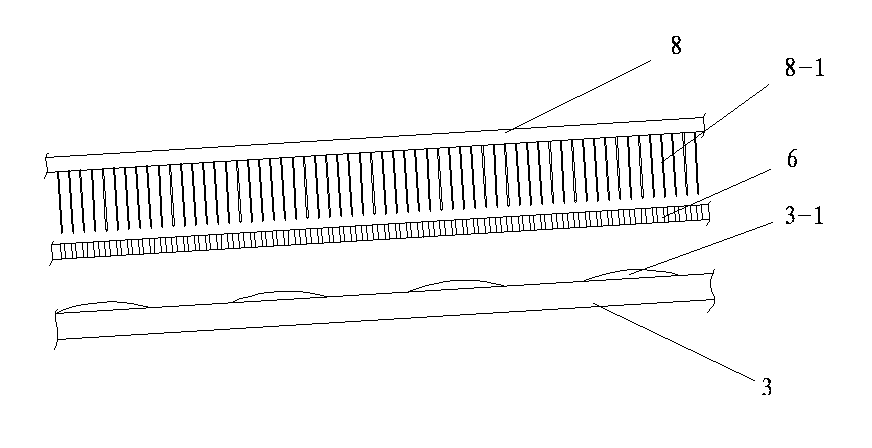

[0020] Connect the bottom plate 3 at the rear end of the belt conveyor 15, and many arc-shaped protrusions 3-1 are set on the bottom plate 3; see image 3 , the arc-shaped protrusion 3-1 starting point tangent on the bottom plate 3 is less than 5° from the bottom plate, and the arc length is 20-40mm;

[0021] The bottom plate 3 is arranged on the bottom bracket 1, wherein the bottom bracket 1 at the rear end can be designed as a telescopic structure, that is, the bottom bracket 1 at the rear end is divided into the upper section 1-1 of the bottom bottom bracket at the rear end and the lower section 1-2 of the bottom bottom bracket at the rear end, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com