Forced flow cooling low-temperature section directly overlapped with high-temperature superconductor stack

A high-temperature superconducting and low-temperature section technology, applied in the direction of superconducting magnets/coils, magnetic objects, electrical components, etc., can solve problems such as improper operation, leakage, and difficult repair, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

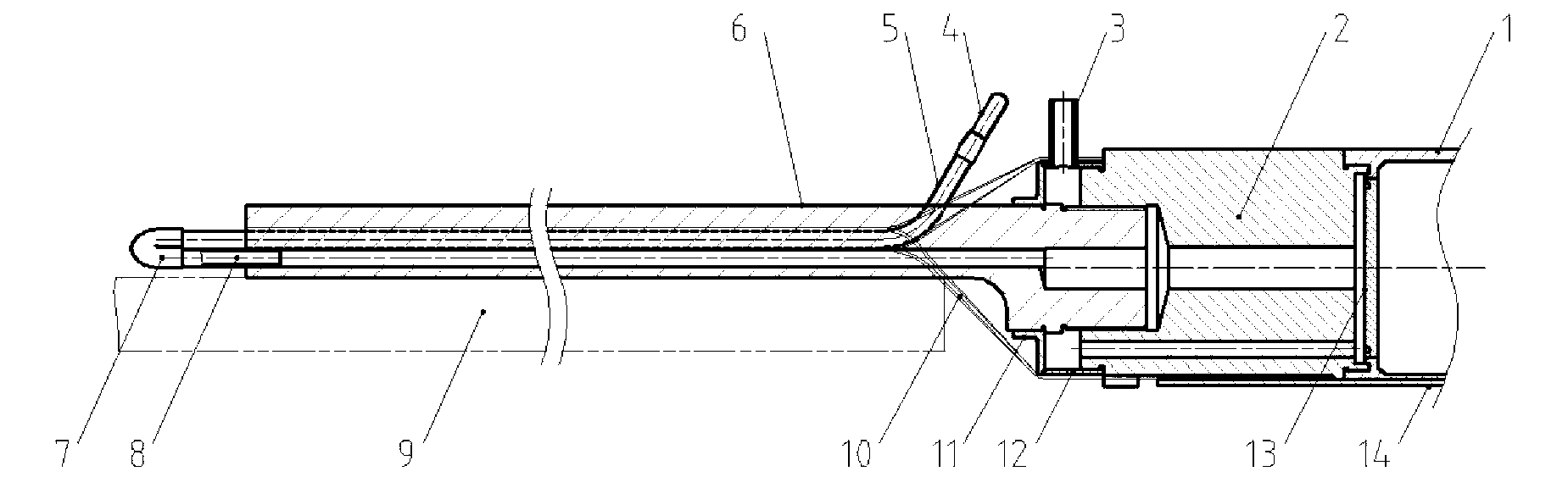

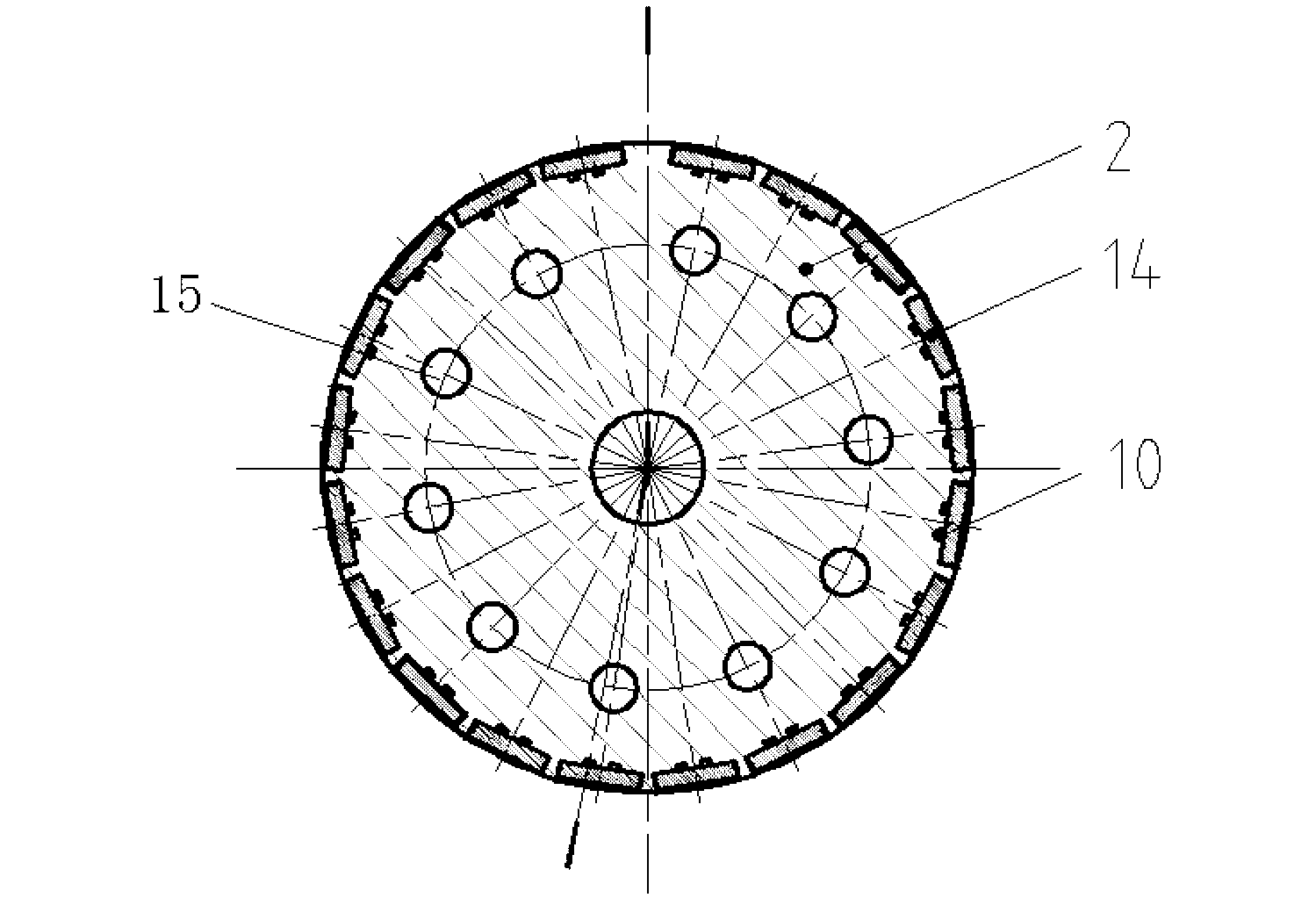

[0016] like figure 1 , figure 2 shown. A forced-flow cooling low-temperature section directly overlapped with a high-temperature superconducting stack, including a cold-end copper structure 2, a stainless steel shunt 1 brazed at one end of the cold-end copper structure 2, and a brazed cold-end copper structure 2 The stainless steel sleeve 12 at the other end, the side wall of the stainless steel sleeve 12 is provided with a helium outlet 3, a stainless steel blind plate 13 is sealed and welded between the stainless steel shunt 1 and the end face of the cold-end copper structural part 2, and the cold-end copper after brazing The structural part 2 and the stainless steel shunt 1 constitute the carrier, and the side wall of the carrier is integrally processed with grooves distributed in a circumferential array, and also includes a copper joint 6 that passes through the stainless steel sleeve 12 at one end and is threaded into the copper structural part 2 at the cold end, The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com