Construction method for integral straight middle wall type double-arch tunnel

A construction method, the technology of straight middle wall, which is applied in tunnel, tunnel lining, earthwork drilling and mining, etc., can solve the problem of water leakage at the top of middle wall, poor stress at the connection point of straight middle wall, and increased land occupation of adjacent structures outside the tunnel, etc. problems, to achieve the effect of improving the force of the middle wall, avoiding water leakage, and reducing the infiltration of surface leakage and water infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

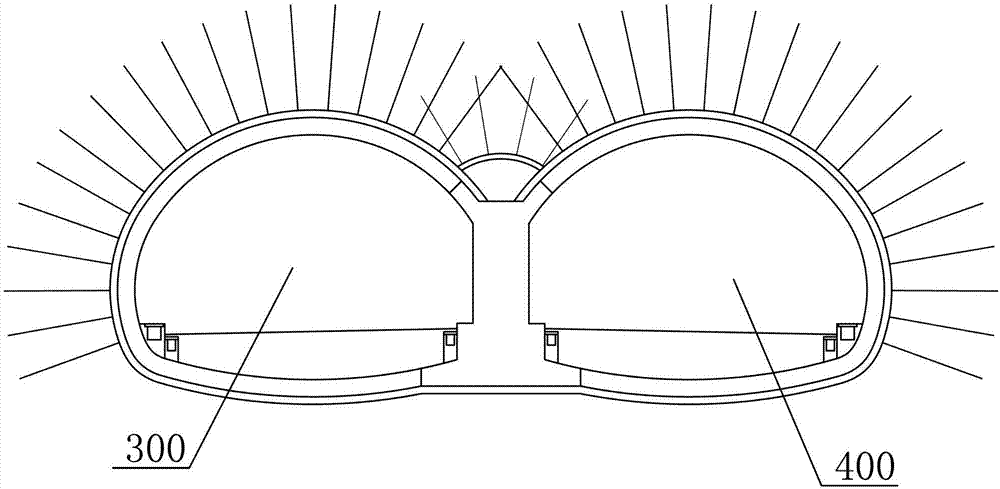

[0070] Such as Figures 1 to 18 As shown, a construction method for an overall straight mid-wall type double-arch tunnel comprises the following steps:

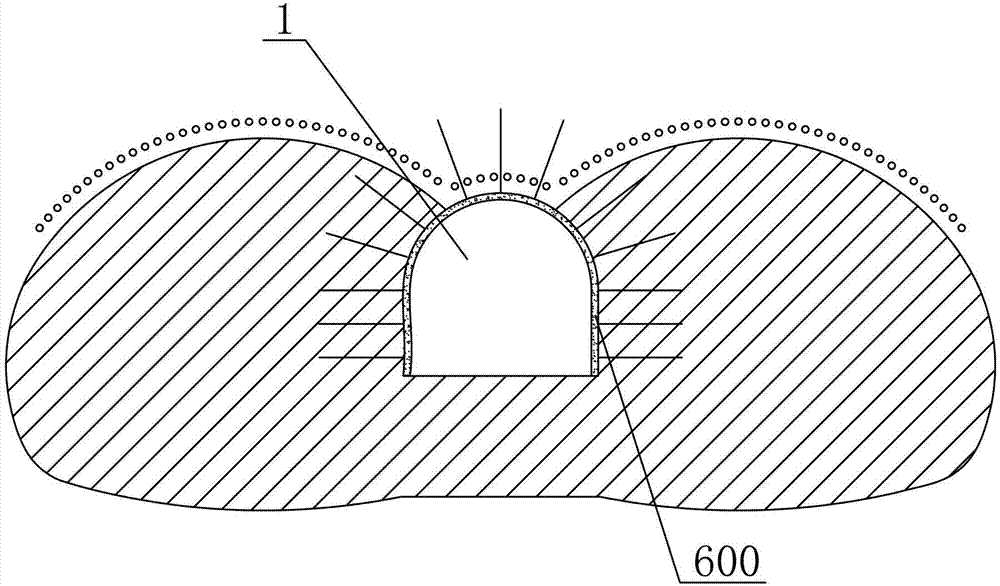

[0071] Ⅰ. Excavate the intermediate pilot tunnel according to the design requirements, and carry out the initial support of the intermediate pilot tunnel;

[0072] Step 1: Excavate the upper steps of the pilot tunnel according to the design requirements 1, carry out the initial support of the pilot tunnel 600;

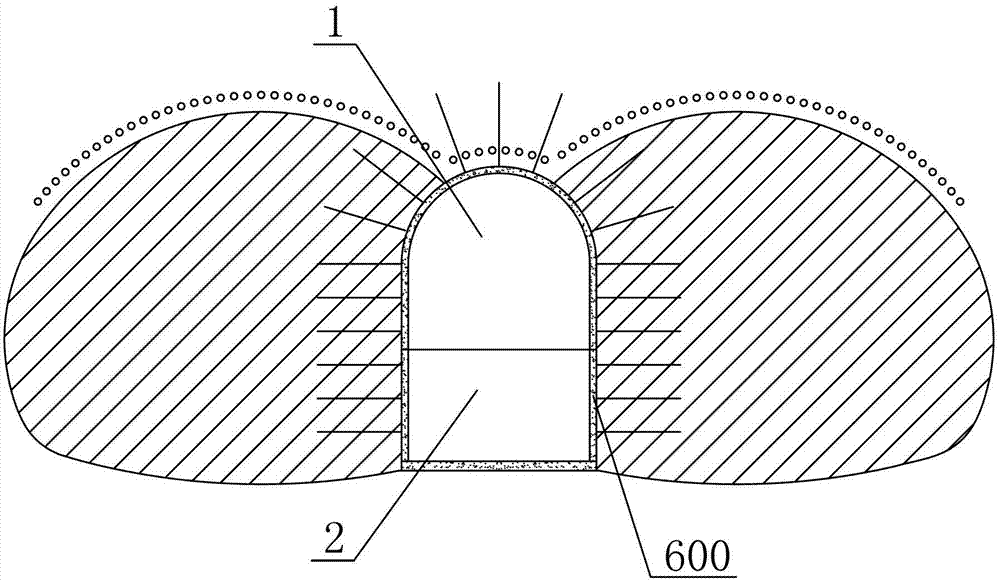

[0073] Step 2: Excavate the lower steps of the pilot tunnel according to the design requirements 2. Perform the initial support of the pilot tunnel 600;

[0074] Ⅱ. The middle wall of the double-arch tunnel is constructed in the middle pilot tunnel, and there is a hollow on the top of the middle wall between the top of the middle wall and the top wall of the middle pilot tunnel;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com