Vertical pile positioning landing stage

A floating wharf and piling technology, applied in climate change adaptation, coastline protection, jetty and other directions, can solve the problems of inconvenient hoisting and installation, high difficulty in operation, harsh construction environment, etc., and achieve strong ability to absorb waves, disassembly and installation. Easy, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

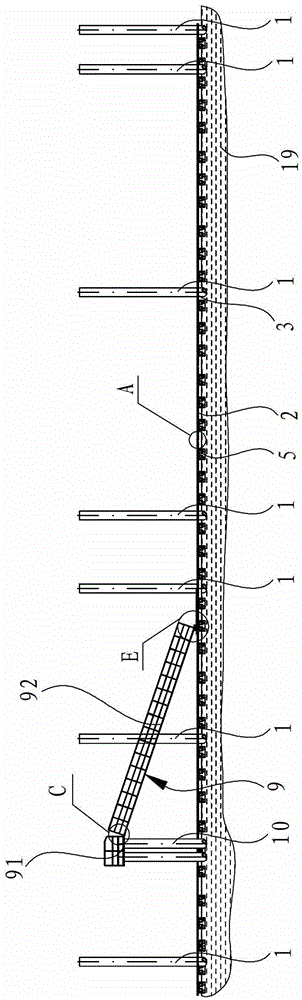

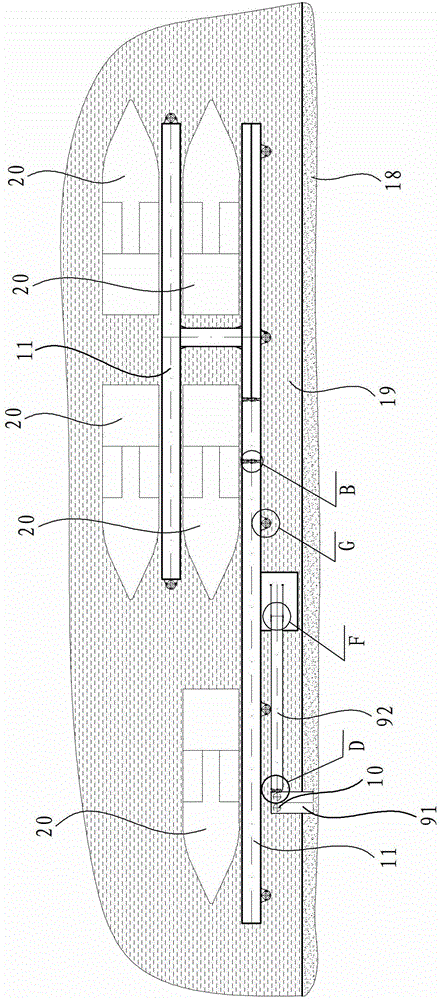

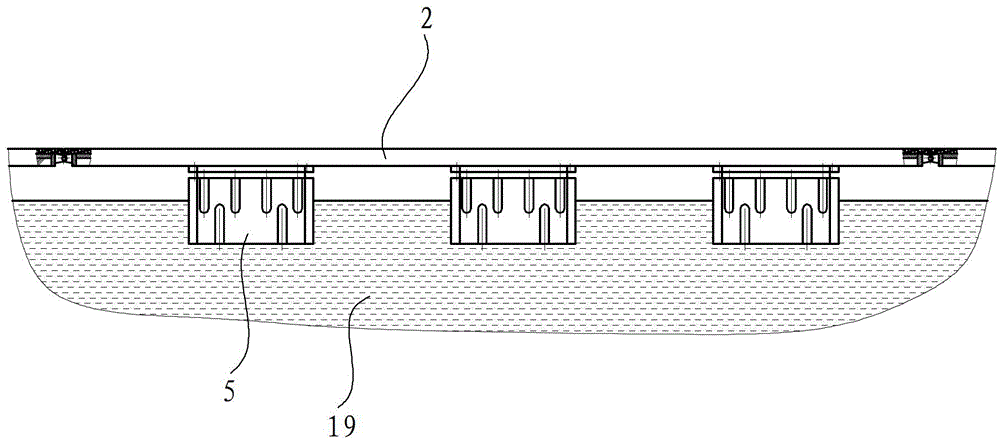

[0042] Such as figure 1 and figure 2 As shown, the piling positioning floating wharf in this embodiment includes components such as pilings 1, auxiliary pilings 10, bridge body skeleton body 6, positioning ring 3, pontoon 5, channel 9, bridge deck 11, and each module The components are fixedly connected by connecting pieces resistant to seawater and seawind erosion, and the yacht 20 is docked on the moored sea surface close to the bridge deck 11 . Wherein, the upright pile 1 and the auxiliary upright pile 10 are both arranged on the seabed and exposed to the sea surface, and can be further fixed with seawater erosion-resistant cement while being arranged on the seabed. The auxiliary pile 10 is close to the coast 18, and the channel 9 is arranged between the coast 18 and the bridge frame body 6.

[0043] Such as Figure 3 to Figure 5 As shown, the bridge skeleton body 6 is an integral structure, which is formed by connecting multiple unit frames 2, and each unit frame 2 use...

Embodiment 2

[0047] Such as Figure 11 to Figure 17 As shown, the floating pier of this embodiment is the same as the floating pier of Embodiment 1 except that the channel structure is different. The channel 9 of this embodiment includes a fixed section 91 and a movable section 92. Between the auxiliary pile 10 , the upper end of the movable section 92 is hinged to the fixed section 91 , and the lower end of the movable section 92 is slidably connected to the bridge deck 11 . Specifically, the movable section 92 specifically includes components such as an upper beam frame 92a, a lower beam frame 92b, a step pedal 92c, a first pulley 92d, and a second pulley 92e. There are two upper beam frames 92a, which are parallel to each other and obliquely arranged on both sides of the channel 9, and the top of the upper beam frame 92a is hinged with the fixed section 91 erected at the end of the auxiliary pile 10 through a hinge shaft 93, and the lower beam frame 92b The bottom end is equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com