Wetting and ironing method for spinning fiber bundle and PTC ironing device used in the method

An ironing device and fiber bundle technology, applied in textiles and papermaking, etc., can solve the problems that the heating wire is prone to open fire, the heating wire is prone to fire, and is difficult to accurately control, and achieves good evenness and uniformity. The effect of reducing hairiness and heating power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

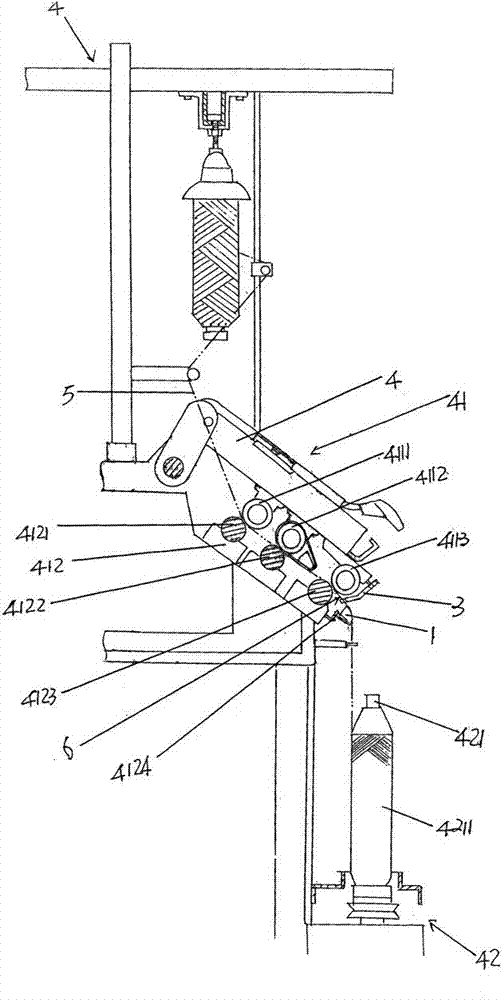

[0026] See figure 1 with figure 2 ,in figure 1 The ring spinning frame 4 is shown in the structural system of the well-known technology. The ring spinning frame 4 has a twisting device 41 and a winding device 42. The twisting device 41 includes a cradle 411 and a roller seat 412. The rear and middle top rollers 4111, 4112 and the front top roller 4113 are pivoted on the cradle 411, and the rear, middle roller 4121, 4122 and the front roller 4123 are pivoted on the roller seat 412 to figure 1 The position state shown is an example. The right side of the front top roller 4113 and the front roller 4123, that is, the direction in which the spinning fiber bundle 5 travels as shown in the figure, constitutes a twisting triangle region 6 known in the industry. The rear, middle and front top rollers 4111, 4112, 4113 correspond to the rear, middle and front rollers 4121, 4122, 4123 respectively.

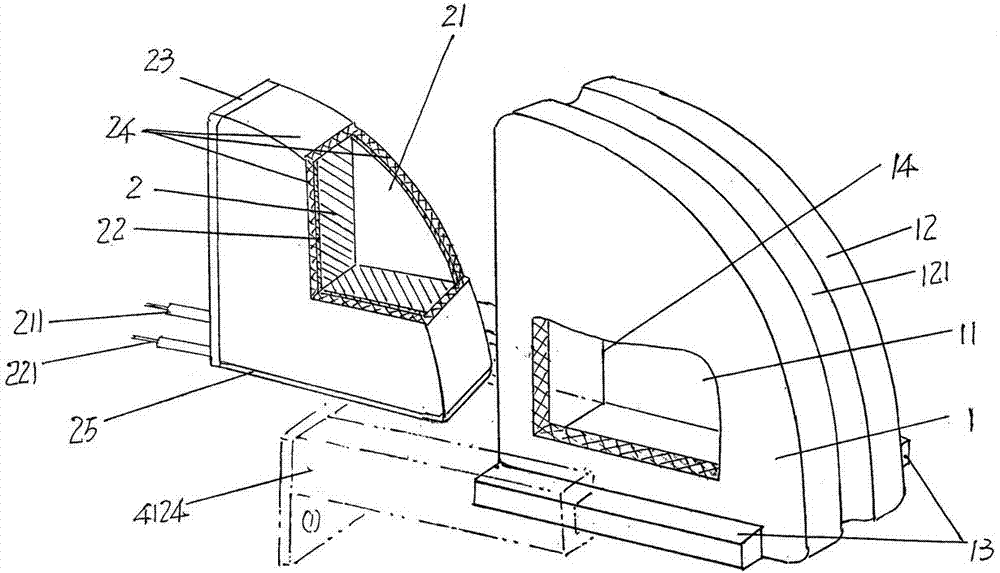

[0027] in figure 2 The PTC ironing device used in the wetting and ironing method for spinni...

Embodiment 2

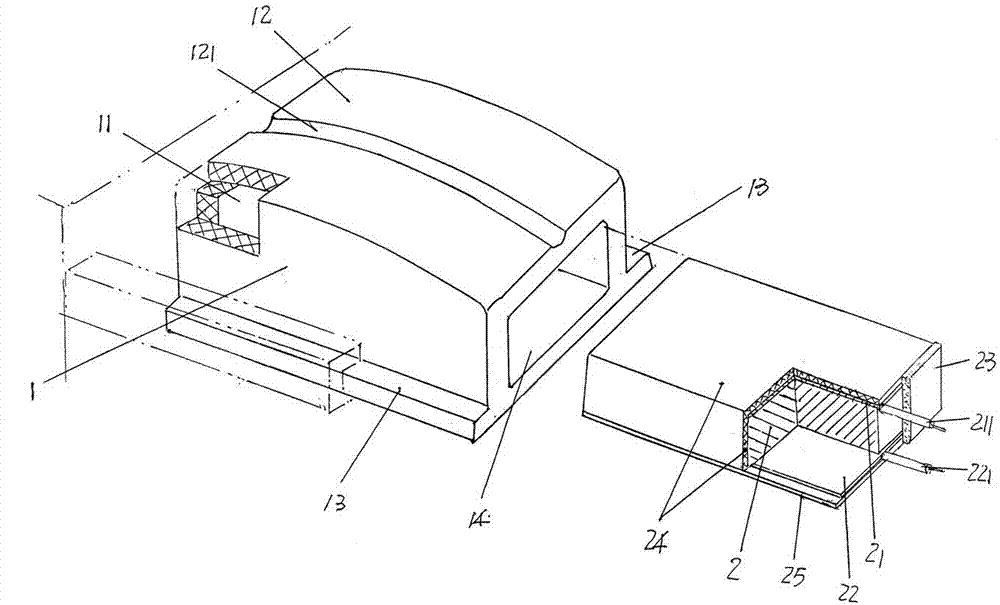

[0032] Please see image 3 ,will figure 2 Replace the PTC ironing device of the structure shown with image 3 The structure shown and assembled with the ironing head fixing seat 4124, where: image 3 The yarn guide surface 12 of the ironing head 1 of the PTC ironing device of the structure shown is designed as a parabolic surface, and the positive temperature coefficient thermal element 2 is in the shape of a rectangular body. The raw material of the spinning fiber bundle 5 is changed to cotton fiber and acrylic fiber in a weight ratio of 1:1, the traveling speed of the textile fiber bundle 5 is changed to 60m / min, and the moisture content after wetting by the wetting device 3 is 6 -10%, the ironing temperature of the PTC ironing device, that is, the temperature of the ironing head 1 is changed to 150-170℃, the Curie point temperature of the positive temperature coefficient thermal element 2 is changed to 190℃, the working voltage of the PTC ironing device That is, the working ...

Embodiment 3

[0034] See Figure 4 And combine figure 1 , The fiber of the spinning fiber bundle 5 is changed to pure cotton fiber, the traveling speed is changed to 125m / min, the moisture content after wetting is changed to 24-32%, and the ironing temperature of the PTC ironing device is the ironing head 1. The ironing temperature is changed to 150-220℃, the Curie point temperature of the positive temperature coefficient thermal element 2 is changed to 300℃, the working voltage of the PTC ironing device, that is, the working voltage of the positive temperature coefficient thermal element 2 is changed to 240V, Will be by figure 1 The structure of the PTC ironing device shown is changed to Figure 4 The structure shown in Figure 4 The middle ironing head 1 is changed to a tubular body, and an inner sleeve 111 is formed in the center of the tubular positive temperature coefficient thermal element cavity 11. The inner sleeve cavity of the inner sleeve 111 is formed as a tubular yarn guide sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com