Latent single-component LCD (liquid crystal display) packaging adhesive

A latent, one-component technology, applied in adhesives, epoxy resin glue, adhesive types, etc., can solve the problems of poor compatibility between curing agent and substrate, reduce large-scale production, troublesome use, etc., and achieve saturated water absorption Low rate, good latency, and the effect of preventing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Take 1 mol of dicyandiamide and 1 mol of formaldehyde, adjust the pH of the system to 9 with NaOH solution, and then heat it to 80°C to react until the formaldehyde content of the system is lower than 3%; then add 0.9 mol of propylene oxide, Heat the reaction at 130°C for 3h, and distill off low molecular weight substances at 70°C under reduced pressure to obtain a latent liquid curing agent for use.

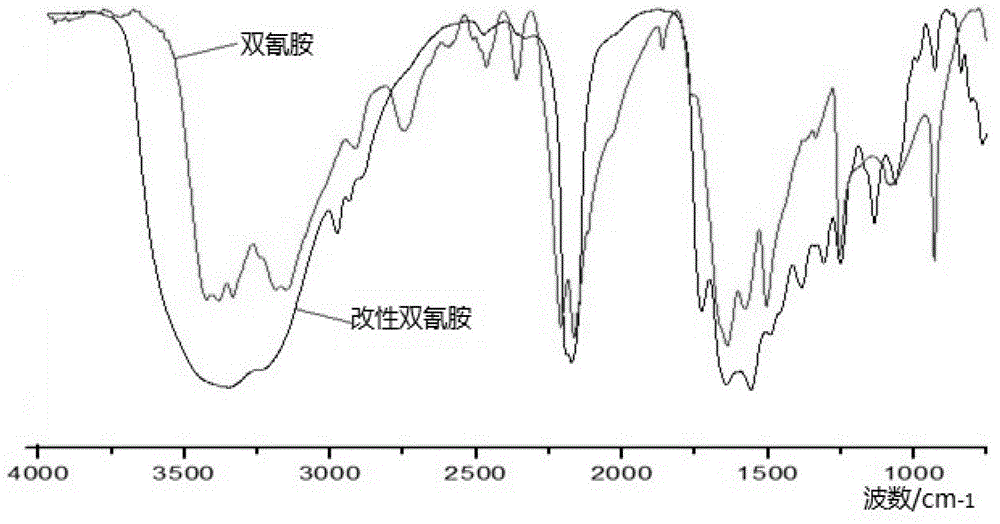

[0026] The infrared spectrogram (IR) of the latent liquid curing agent that makes is as figure 1 shown, from figure 1 It can be seen that the prepared latent liquid curing agent is at 1064cm ‐1 -1384cm ‐1 There are many characteristic absorption peaks between, and at 3000cm ‐1 -3250cm ‐1 There are characteristic peaks, indicating that the reaction generates ‐OH; at 2976cm ‐1 Appeared near-CH3 characteristic absorption peak, explained the introduction of methyl group in the modified dicyandiamide after reaction; ‐1 NH at 2 The doublet becomes only at 3349cm in t...

Embodiment 2

[0032] (1) Take 1 mol of dicyandiamide and 1.2 mol of formaldehyde, adjust the pH of the system to 9.5 with triethanolamine solution, and then heat to 75°C to react until the formaldehyde content of the system is lower than 3%; then add 1.3 mol of propylene oxide, Heat the reaction at 110°C for 5h, and distill off low molecular weight substances under reduced pressure at 80°C to obtain a latent liquid curing agent for use.

[0033] (2), based on the percentage of the total mass of raw materials, weigh E-44 epoxy resin accounting for 60% of the total mass of raw materials, 12% random carboxylated nitrile rubber, 15% self-made curing agent, and 1% KH- 560 silane coupling agent, 1% of KH‐570 silane coupling agent, 1% of DMF were added to a 500ml beaker, stirred evenly with a glass to obtain mixture A;

[0034] (3), then take 0.2% of the total mass of raw materials BYK‐066N defoamer, 0.1% of KLE‐42 leveling agent, 0.2% of BYK‐110 wetting and dispersing agent, 12% of calcium carbon...

Embodiment 3

[0037](1) Take 1 mol of dicyandiamide and 1.1 mol of formaldehyde, adjust the pH of the system to 10 with NaOH solution and dimethylethanolamine solution, heat to 80°C for reaction, and wait until the formaldehyde content of the system is lower than 3%; then add 1.0 mol propylene oxide, heated at 120°C for 4 hours, and distilled off low molecular weight substances at 80°C under reduced pressure to obtain a latent liquid curing agent for use.

[0038] (2), based on the percentage of the total mass of raw materials, take by weighing E-44 epoxy resin accounting for 69% of the total mass of raw materials, 5 parts of random carboxylated nitrile rubber, 3% carboxyl-terminated nitrile rubber, 11% of homemade Curing agent, 1% KH‐550 silane coupling agent, 0.5% DMF, added to a 500ml beaker, stirred evenly with a glass to obtain mixture A;

[0039] (3), then take 0.3% of the total mass of raw materials BYK-066N defoamer, 0.1% of TG-440 leveling agent, 0.1% of BYK-110 wetting and dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com