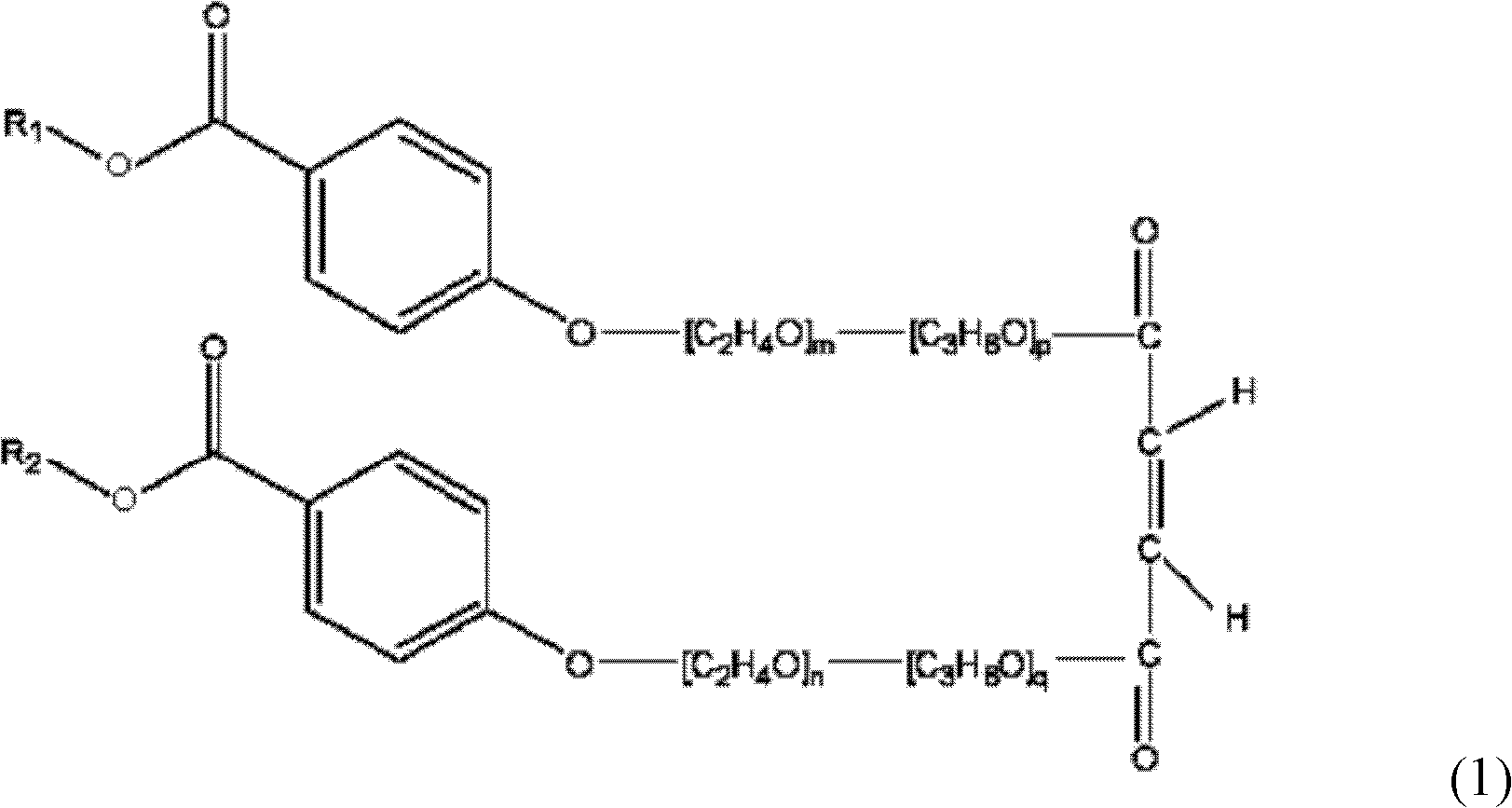

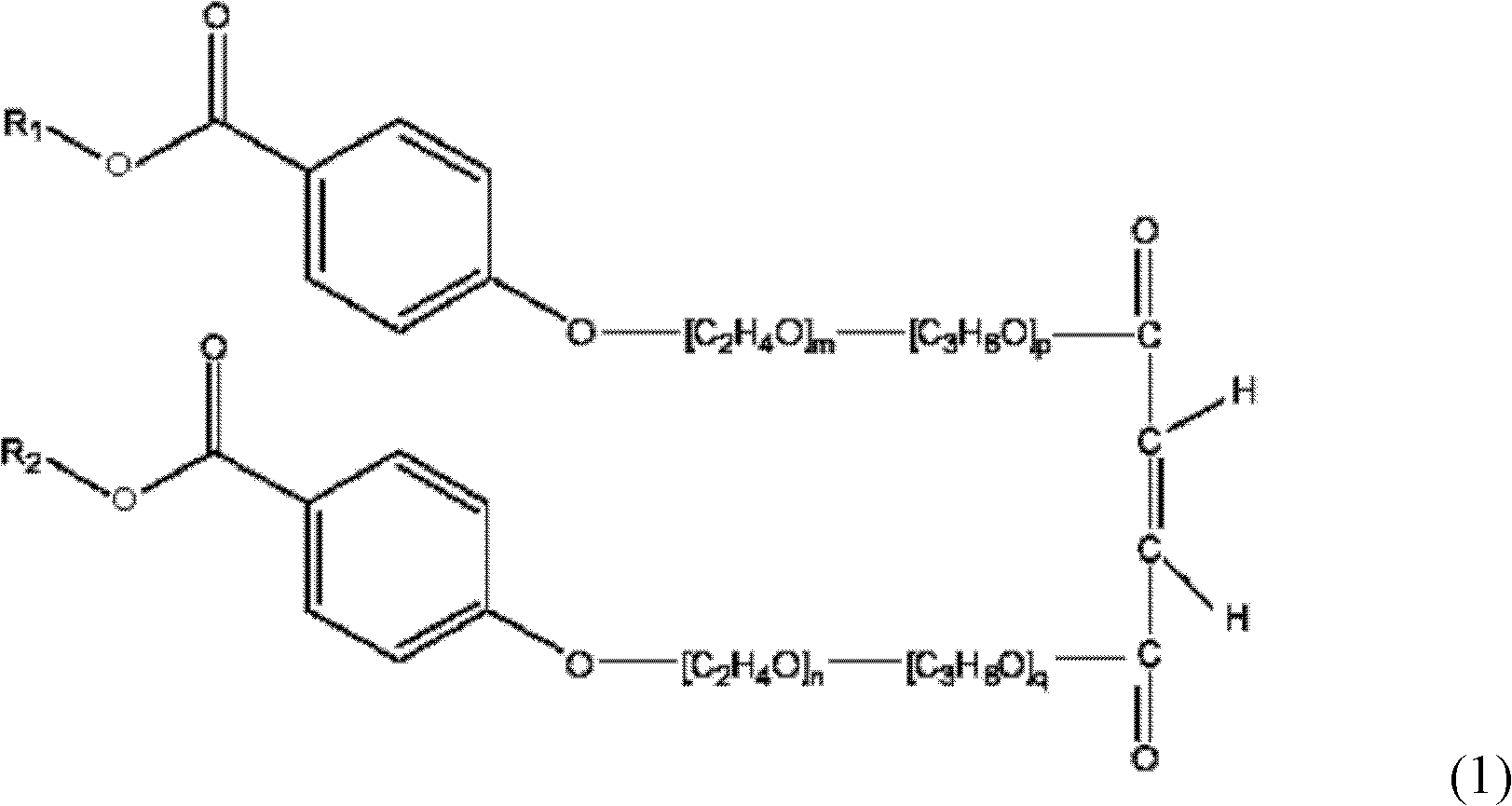

Low molecular weight polyether water reducing agent, its preparation method and application

A low-molecular-weight polyether and polyether technology, applied in the field of low-molecular-weight polyether and its preparation, can solve the problems of weakening the adsorption of polycarboxylate water-reducers, reducing the working performance of polycarboxylate water-reducers, and reducing slump The effect of degree loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

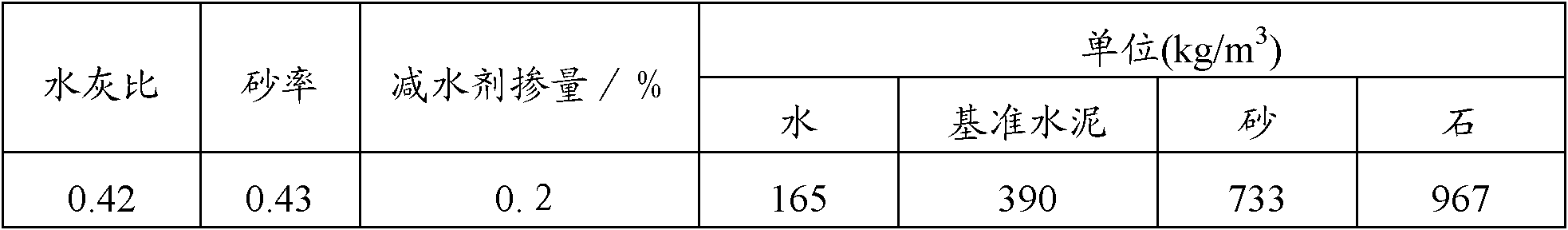

Examples

Embodiment 1

[0031] Under negative pressure conditions, add 131 grams of methyl p-hydroxybenzoate and 2.9 grams of catalyst KOH in the autoclave, then carry out nitrogen replacement to the autoclave, start stirring, and the reactor material is heated, when the temperature is 80~100 At ℃, add 10 grams of alkyl ethylene oxide to initiate the polymerization reaction. After the temperature continues to rise and the pressure drops, a total of 1310 grams of alkyl ethylene oxide is continuously and stably added to the reactor. During continuous feeding, the polymerization reaction temperature is controlled at 120 ~ 130°C, after the continuous feeding, carry out the aging reaction at 120-130°C, when the pressure of the kettle no longer drops, start to cool down the reactor material, the temperature drops to 80-90°C, and neutralize it to pH 6 with glacial acetic acid ~7 discharges.

[0032] The samples obtained in the above steps were distilled under reduced pressure to remove low boiling substance...

Embodiment 2

[0034] Under negative pressure conditions, add 166 grams of ethyl p-hydroxybenzoate and 3.86 grams of catalyst KOH to the autoclave, then replace the autoclave with nitrogen, start stirring, and heat the materials in the autoclave. At 100°C, add 10 grams of alkyl ethylene oxide to initiate the polymerization reaction. After the temperature continues to rise and the pressure drops, continuously and stably add a total of 1750 grams of alkyl ethylene oxide to the reactor. During continuous feeding, the polymerization reaction temperature is controlled at 120 ~130°C, after the continuous feeding, carry out the aging reaction at 120~130°C, when the pressure of the kettle no longer drops, start to cool down the reactor material, the temperature drops to 80~90°C, and neutralize it to pH with glacial acetic acid 6~7 discharge.

[0035] The samples obtained in the above steps were distilled under reduced pressure to remove low boiling substances. Then all proceed to esterification uni...

Embodiment 3

[0037]Under negative pressure conditions, add 131 grams of methyl p-hydroxybenzoate and 2.9 grams of catalyst KOH in the autoclave, then replace the autoclave with nitrogen, start stirring, and heat the materials in the autoclave. At 100°C, add 10 grams of alkyl ethylene oxide to initiate the polymerization reaction. After the temperature continues to rise and the pressure drops, continuously and stably add a total of 1310 grams of alkyl ethylene oxide to the reactor. During continuous feeding, the polymerization reaction temperature is controlled at 120 ~130°C, after the continuous feeding, carry out the aging reaction at 120~130°C, when the pressure of the kettle no longer drops, add 10 grams of alkyl propylene oxide to initiate the polymerization reaction, after the temperature continues to rise and the pressure drops, continue Add a total of 48 grams of alkyl propylene oxide to the reactor stably. During the continuous feeding, control the polymerization reaction temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com