Preparation method and application of polyoxyethylene-based polymer filtrate reducer

A fluid loss control agent, allyl polyoxyethylene ether technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problem of poor drilling fluid rheological properties, high temperature resistance, high salinity resistance problems such as poor ability, to achieve the effect of good water loss reduction ability, mild synthesis conditions and easy polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0008] Example 1: Preparation method of polyoxyethylene-based polymer fluid loss reducer

[0009] First put 0.006mol of allyl polyoxyethylene ether into a three-neck bottle, add 20.0mL of deionized water, put it in a water bath and heat it to dissolve; add 0.029mol of 2 -Acrylamide-2-methylpropanesulfonic acid and 0.084mol of acrylamide, then add 82mL of deionized water to make a solution with a total monomer mass concentration of 15%, and use potassium persulfate and sodium bisulfite in a mass ratio of The 1:1 mixing system is the initiator, the addition amount is 0.2% of the total mass of the monomer, and the NaOH solution with a mass percent concentration of 50% is used to adjust its pH value to 9. After stirring and mixing evenly, the above mixed solution is mixed in The reaction was carried out at 60° C. for 3 hours. A gel-like product is obtained through the copolymerization reaction, which is purified and extracted with absolute ethanol, sheared and granulated, vacuum-...

Embodiment 2

[0010] Embodiment 2: the preparation of drilling fluid base slurry

[0011] According to the Petroleum and Natural Gas Industry Standard of the People's Republic of China SY / T5241-91 "Evaluation Procedures for Fluid Loss Control Agents for Water-based Drilling Fluids", prepare freshwater-based slurry, salt-water-based slurry and polymer-based slurry.

[0012] (1) Preparation of fresh water base slurry: add 40g calcium bentonite and 2g anhydrous NaCO to 1000mL water 3 , stirred at a high speed for 20 minutes, and sealed at room temperature for 24 hours to obtain a freshwater base slurry.

[0013] (2) Preparation of brine-based slurry: add 40g of calcium bentonite and 2g of anhydrous Na to 1000mL of distilled water 2 CO 3 , and then add a certain amount of NaCl, stir at high speed for 20 minutes, and keep in airtight storage at room temperature for 24 hours to obtain the brine-based slurry.

[0014] (3) Preparation of polymer slurry: put the prepared base slurry into a high s...

Embodiment 3

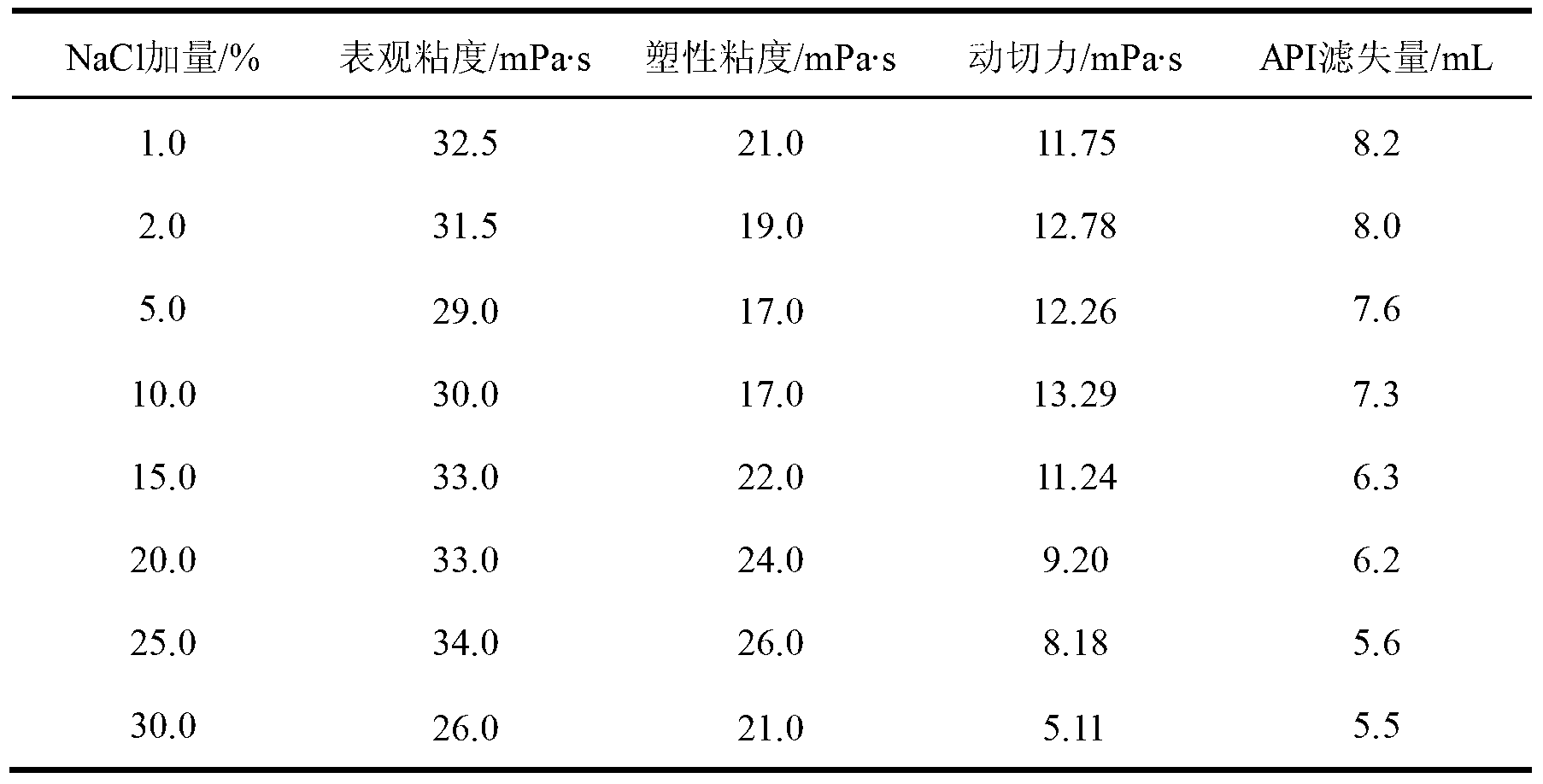

[0015] Example 3: Salt Resistance Performance of Polymer Fluid Loss Control Agent

[0016] Add polymer fluid loss reducer with a mass percentage concentration of 1.2% to the fresh water slurry, stir evenly, then add different amounts of NaCl, stir at high speed for 5-10 minutes, test the API fluid loss and rheological properties of the drilling fluid, Evaluation of its salt resistance performance, the results are shown in Table 1.

[0017] Table 1 Salt resistance of polymer-based pulp

[0018]

[0019] It can be seen from Table 1 that with the increase of NaCl content in the mud system, the water loss of the drilling fluid gradually decreases. When the salt content is 30%, the fluid loss is the lowest, reaching 5.5mL, indicating that the polymer fluid loss additive is salt-resistant Ability is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com