Method for producing vegetalitas fulvic acid/potassium sulfate concentrated solution/vegetalitas organic bacterial manure by utilizing alcohol biologic wastewater

A kind of fulvic acid and plant-based technology, which is applied in the fields of alkali metal sulfite/sulfate purification, organic fertilizer, sewage/sludge fertilizer, etc. It can solve the problems of difficult treatment, waste of potassium resources, and low material utilization rate. , to achieve the effect of improving operation stability, improving product quality and broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

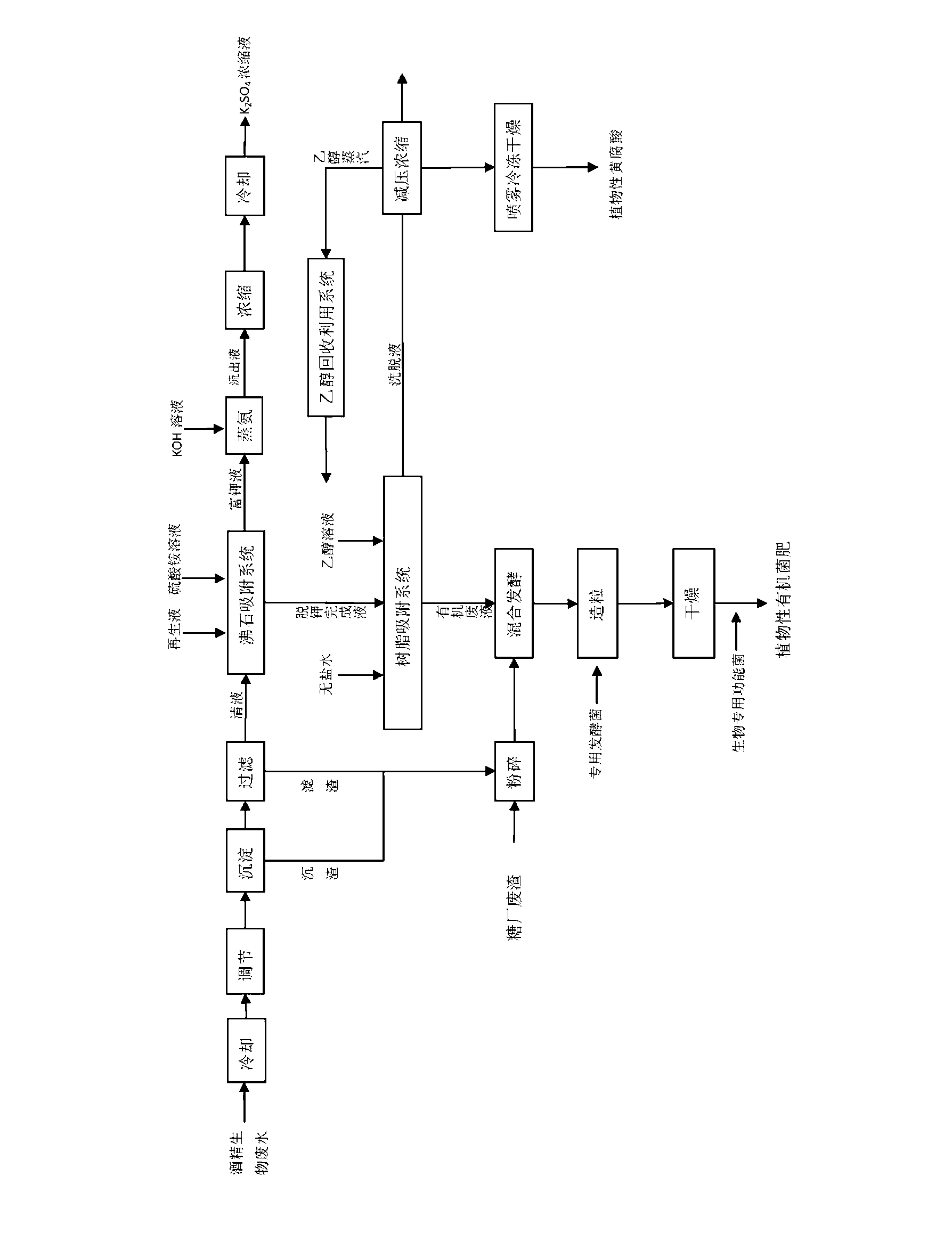

[0088] Such as figure 1 Shown, a kind of method that utilizes alcohol biological wastewater to produce plant-based fulvic acid / potassium sulfate concentrate / plant-based organic bacterial fertilizer.

[0089] The method of producing plant-based fulvic acid is to use alcohol biological wastewater as raw material, and then make plant-based fulvic acid after cooling, conditioning, precipitation, filtration, zeolite potassium extraction, resin adsorption, decompression concentration, and spray freeze-drying. , the process steps are as follows:

[0090] A. cooling

[0091] The alcohol biological wastewater is cooled in the cooling tower to cool the alcohol biological wastewater to 30°C;

[0092] B. to adjust

[0093] The cooled alcoholic biological wastewater enters the regulating tank to adjust the water quality and quantity, so that the wastewater quality and quantity are balanced, and it is convenient to enter the follow-up treatment equipment stably;

[0094] C. Precipit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com