Motor-driven hydraulic power assisted steering pump

A hydraulic power steering and motor-driven technology, which is applied in the direction of fluid steering mechanism, etc., can solve the problems of electric vehicles, limited life, poor safety, etc., achieve real-time fault detection and processing, reduce maintenance costs, and reduce fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The structural features of the present invention will be further described below in conjunction with the accompanying drawings.

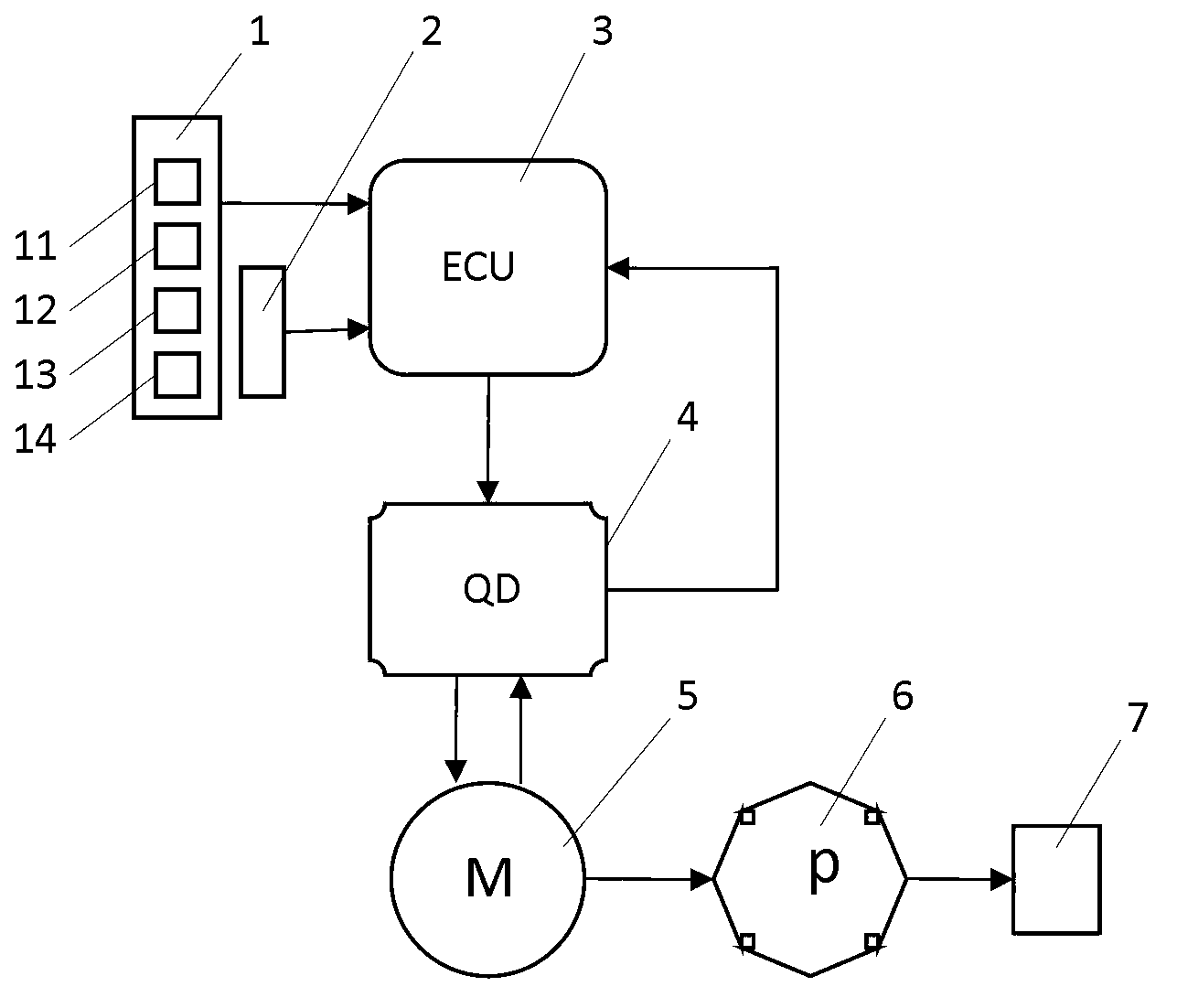

[0023] Such as figure 1 As shown, the hydraulic power steering pump of the present invention includes an electrical interface 1, a temperature sensor 2, an electronic control unit 3 connected to the electrical interface 1 and the temperature sensor 2, a drive circuit 4 connected to the electronic control unit 3, and a drive circuit 4 connected The motor 5, the gear pump 6 connected with the motor 5, the output of the gear pump 6 is connected to the hydraulic circuit interface 7. Further, the electrical interface 1 includes a power interface 11 , an ignition signal input interface 12 , a CAN bus interface 13 and a steering angular velocity signal input interface 14 . The ignition signal input interface 12 inputs the ignition signal to the electronic control unit 3 to control the start of the electronic control unit 3; the electronic control u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com