A batching equipment for producing rice noodles on an industrial scale

A batching equipment and rice noodle technology, applied in the field of rice noodle batching equipment, can solve the problems of large manual operation error, inability to large-scale production, low efficiency, etc., and achieve the effect of increasing production capacity, reducing differences between batches, and improving overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following, the technical solution of the present party will be further explained through specific implementation methods in conjunction with the accompanying drawings.

[0029] In this embodiment, the air jet pump and the rice pump are all known devices, and each control system of the batching equipment is automatically controlled by existing means.

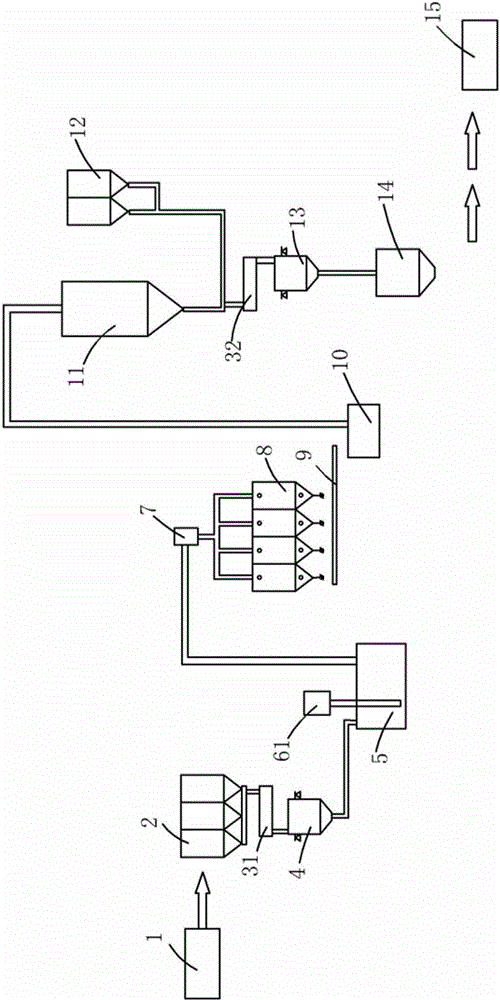

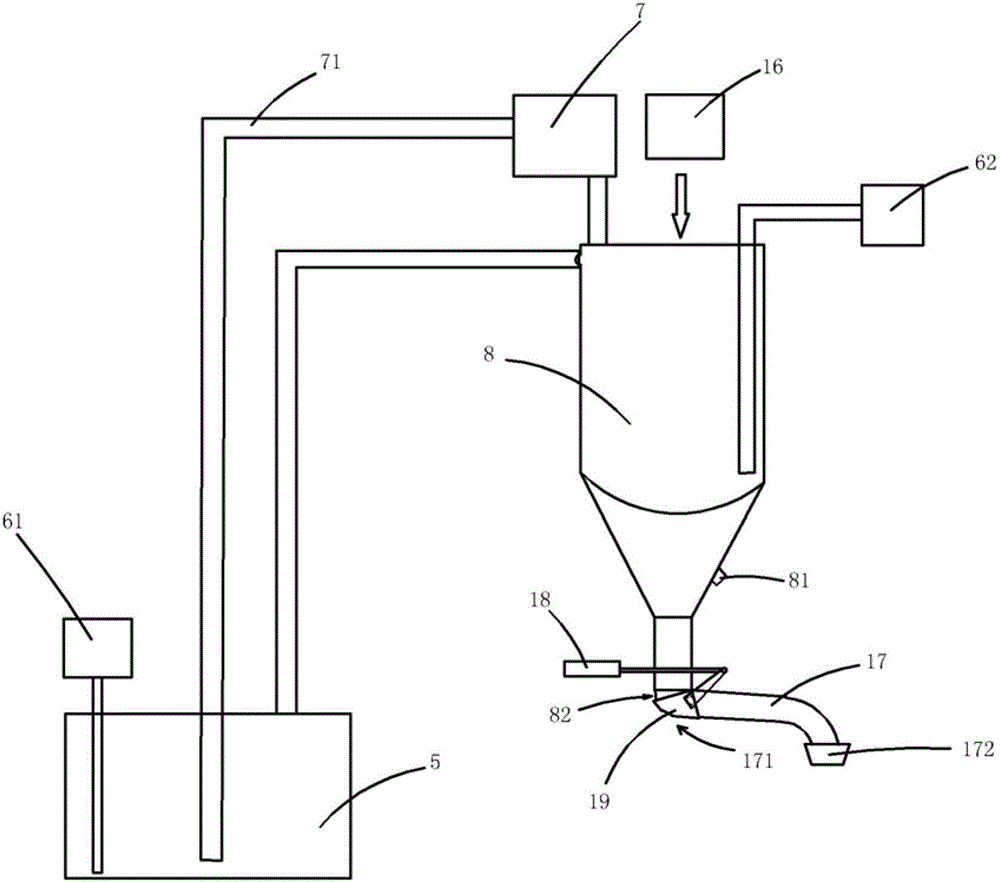

[0030] As shown in the figure, the rice noodle batching equipment is composed of a control system and the equipment body. The equipment body mainly includes a primary batching system, a rice soaking and washing system, a pulverizer and a secondary batching mixing system.

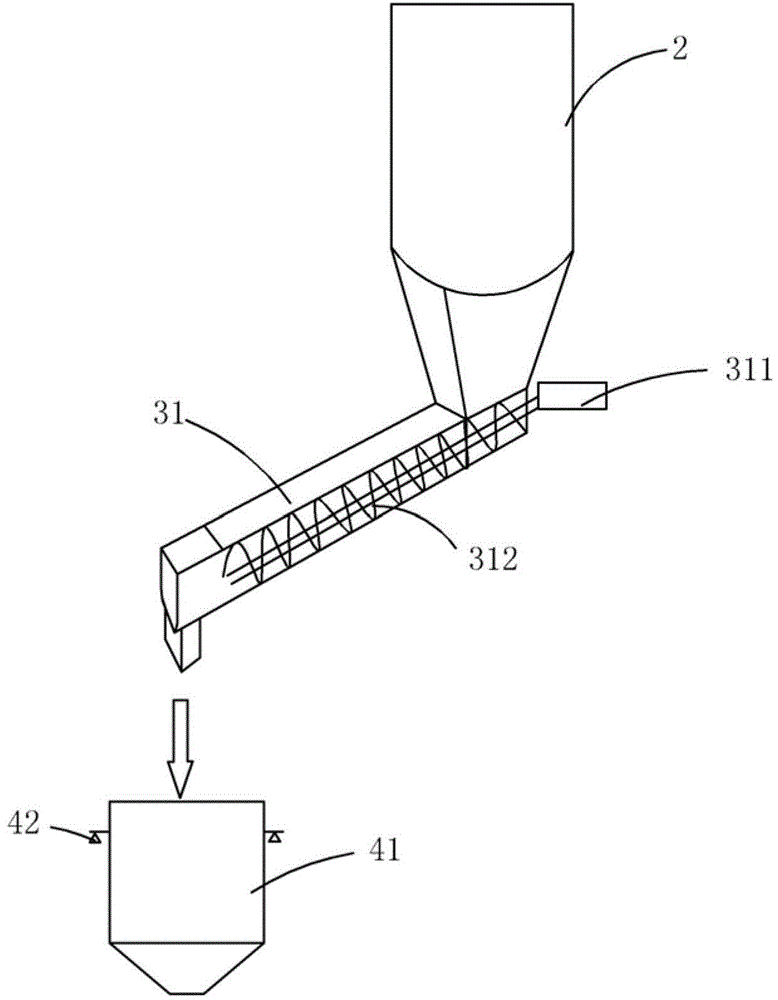

[0031] The main body of the primary batching system includes a main silo 2, a screw conveyor 3 and an automatic weighing device 4; the main silo 2 is used to temporarily store raw materials to be processed from the raw material conveying mechanism 1; the outlet of the main silo 2 passes through A horizontally arranged screw conveyor 31 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com