Intelligent LEDs lamp holder adjusting and controlling system for plant factory cultivation frame

A control system and a cultivation rack technology are applied in the field of automatic height adjustment systems for multi-layer lamp racks in cultivation racks in a plant factory, which can solve the problems of inconvenient operation, inaccuracy, and inability to automatically control and control the adjustment accuracy, and achieve the effect of low light source energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

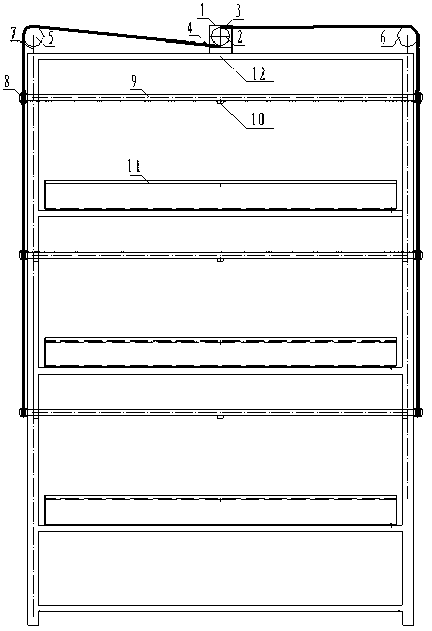

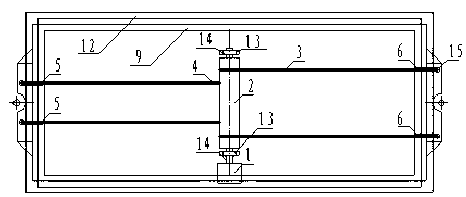

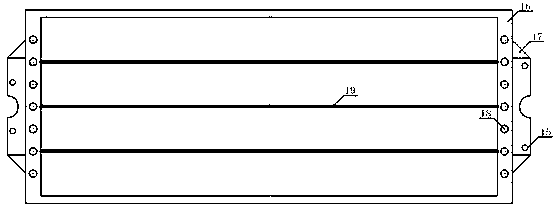

[0028] Such as figure 1 , figure 2 As shown, the plant factory cultivation frame intelligent LEDs light frame control system of the present invention mainly includes a drive group (stepper motor 1, drum 2, drum support bearing 13, drum shaft 14), a transmission group (left flexible suspension steel cable 3, right Flexible suspension steel cable 4, left support roller 5, right support roller 6, support roller support 7), light stand group (adjustable light stand suspension locking device 8, LEDs light stand 9, suspension locking device installation hole 15) , an ultrasonic sensor 10, a system controller, a cultivation frame 12, a cultivation tank 11 and other components.

[0029] The stepping motor 1 can realize positive and negative rotation, and adopts step subdivision technology to realize small-angle step displacement, and realize high-precision a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com