Fermented milk with suppressed sourness and production method thereof

A production method and technology for fermented milk, which are applied in the directions of bacteria, lactobacilli, and dairy products used in food preparation, and can solve problems such as stronger acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Mix 42.0kg of raw milk, 8.0kg of skimmed milk powder (Meiji Milk Industry), and 5.0kg of sugar (Meiji Food Raw Materials Co., Ltd.) with 45.0kg of water. This is how you get raw milk (yogurt mix). This raw material milk was heat-sterilized at 95 degreeC for 5 minutes, and then cooled to 43 degreeC.

[0025] To achieve a content of 2% by weight, lactic acid bacteria fermented powder (a mixed culture of Lactobacillus bulgaricus JCM1002T and Streptococcus thermophilus ATCC19258) was added to raw milk. A 0.15% by weight aqueous solution of phytic acid (50% by weight Tsukino Food Industry) was added to 100% by weight of the raw material milk (fermented raw material) to which lactic acid bacteria fermented powder was added. These raw milks were then fermented in tanks at a temperature of 43°C. When the acidity (acidity) of lactic acid reaches about 0.85%, fermented milk is prepared (made) by cooling the yogurt curd to below 10°C while crushing it. In addition, the acidity ...

Embodiment 2

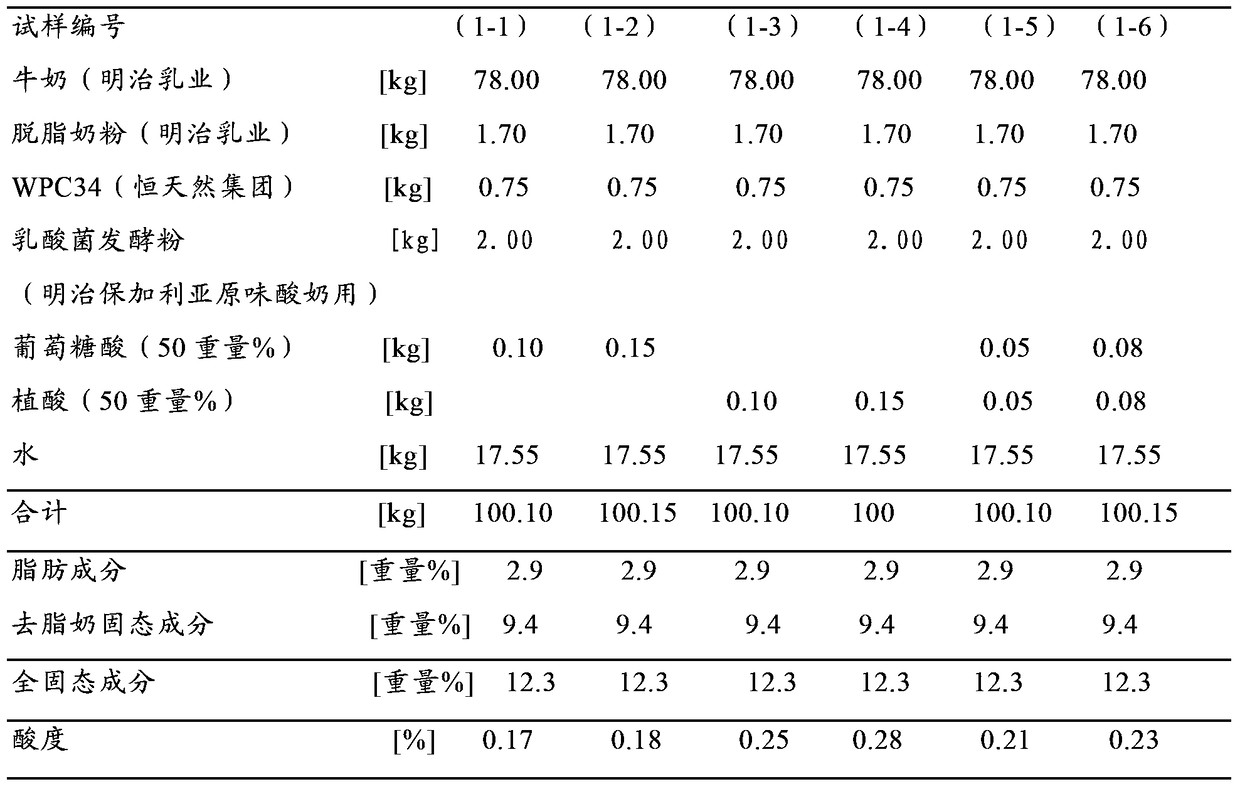

[0030] Raw material milks with different sour components were prepared according to the recipe in Table 1A, and samples 1-1 to 1-6 were obtained.

[0031] [Table 1A]

[0032] Table 1A Formula table of fermented milk (raw milk) with the type of sour material changed

[0033]

[0034]As shown in Table 1A, Sample 1-1 and Sample 1-2 contained gluconic acid as an acid component. Samples 1-3 and 1-4 contained phytic acid as an acid component. Samples 1-5 and 1-6 contained gluconic acid and phytic acid as acid components. These obtained samples 1-1 to 1-6 were fermented at a temperature of 43°C. The fermentation time and the change in the acidity of the fermented milk (raw material milk) are shown in Table 1B.

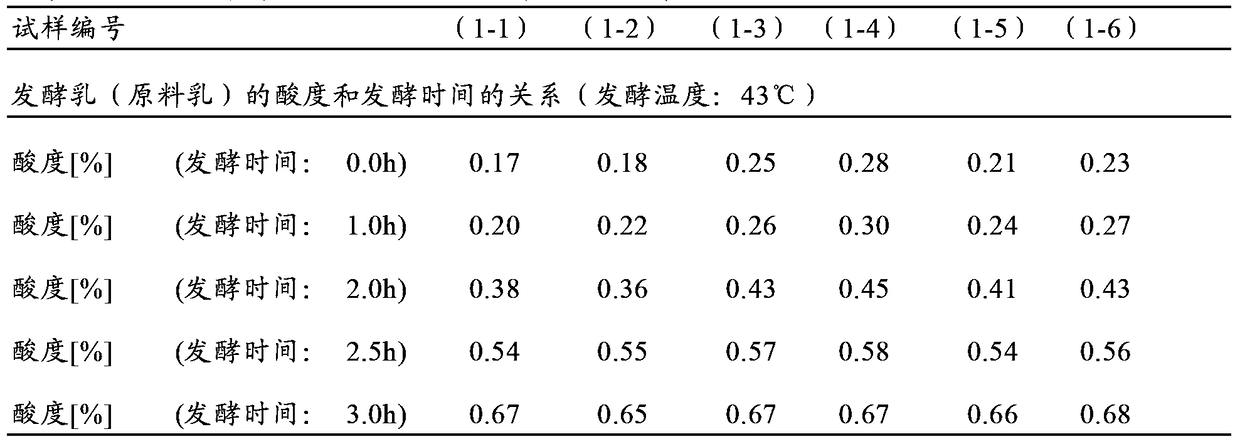

[0035] [Table 1B]

[0036] Table 1B Changes in acidity during fermentation (43°C) of fermented milk (raw milk) with different types of sour ingredients

[0037]

[0038] As can be seen from Table 1B, in any of the above samples 1-1 to 1-6, when the fermentation ti...

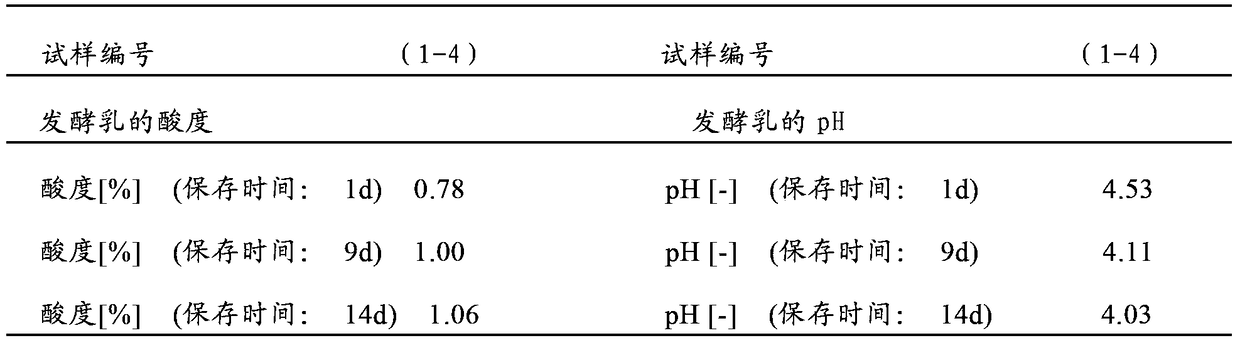

Embodiment 3

[0048] Raw material milks with different sour components were prepared using the recipe in Table 2A, and samples 2-1 to 2-2 were obtained. Sample 2-1 is a sample of an existing product, and sample 2-2 is a sample for a control experiment. Comparing sample 2-2 with sample 2-3, it can be seen that although the amount of acid component added in sample 2-3 is more, the pH of sample 2-3 is also lower than that of sample 2-2. This is considered to be due to the fact that gluconic acid is an acid with a lower pH than lactic acid. These obtained samples 2-1 to 2-3 were fermented at a temperature of 43°C. The fermentation time, the acidity of fermented milk (raw material milk), and the change in pH are shown in Table 2B.

[0049] [Table 2A]

[0050] Table 2A Formula table of fermented milk (raw milk) that changes the type of sour material

[0051]

[0052] [Form 2B]

[0053] Table 2B Changes in acidity and pH during fermentation (43°C) of fermented milk (raw milk) with differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com