Light guide plate

A technology of light guide plate and smooth surface, applied in the field of light guide plate, can solve the problem of poor quality of LED light entrance, and achieve the effect of avoiding the HotSpot phenomenon and increasing the divergence angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

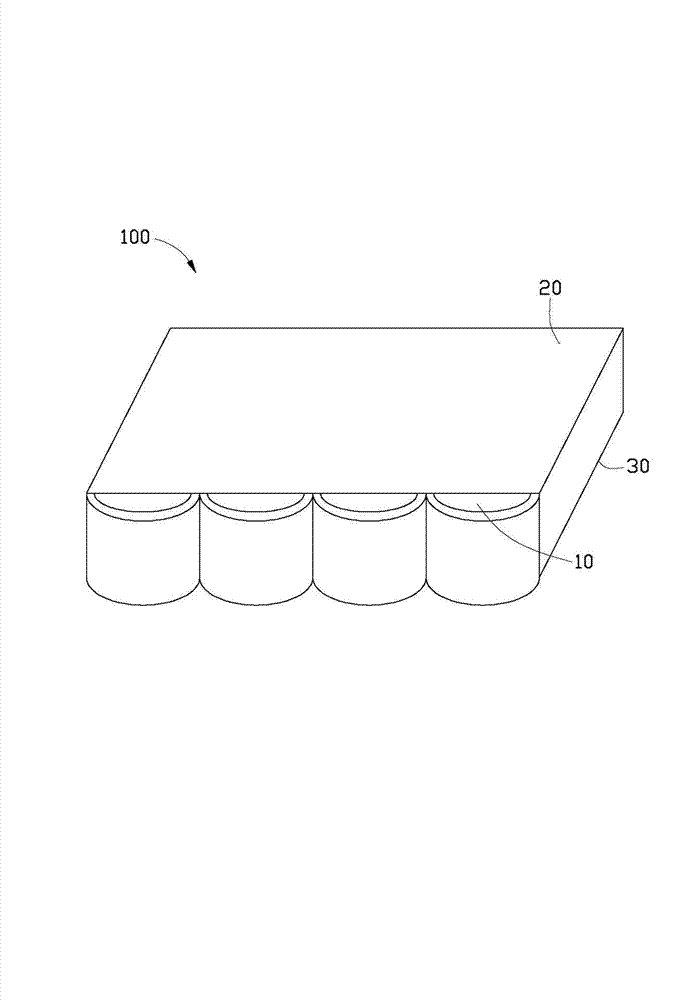

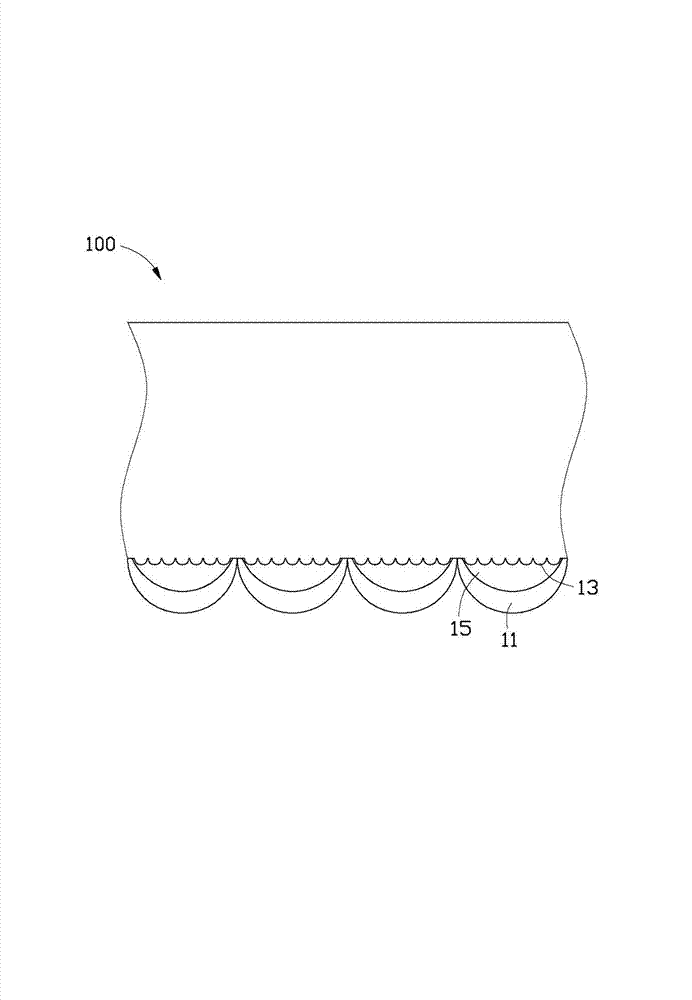

[0012] refer to figure 1 and figure 2 The light guide plate 100 includes a light incident surface 10 , a light exit surface 20 , and a bottom surface 30 opposite to the light exit surface 20 . In this embodiment, the light guide plate 100 is in the shape of a flat plate as a whole, which can be made of acrylic resin, polycarbonate or polyethylene resin and other materials. In other implementation manners, the light guide plate 100 can be set in other shapes as required, such as a wedge shape.

[0013] The light incident surface 10 is provided with a plurality of first microstructures 11 and a plurality of second microstructures 13, the first microstructures 11 are located outside the second microstructures 13, so that the light source needs to pass through the first microstructures 11 Then pass through the second microstructure 13 to enter the light guide plate 100 .

[0014] In this embodiment, the first microstructure 11 has an arc-shaped cross-section, which protrudes f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com