Liquid level sensor with simulating function

A technology of liquid level sensor and analog function, applied in the direction of liquid level indicator, instrument, engine lubrication, etc., can solve the problems of voltage threshold drift, inconvenient operation for users, inability to simulate liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

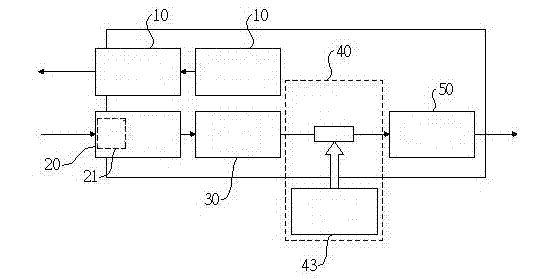

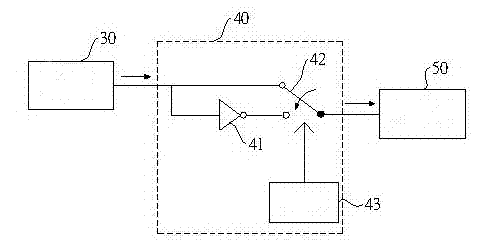

[0050] see figure 1 , the liquid level sensor includes a light emitting module 10, a light receiving module 20, a signal processing module 30, an analog module 40 and an output module 50, wherein:

[0051] The light emitting module 10 can emit light to the material or liquid to be measured. In this embodiment, the light emitting module 10 is further provided with a light modulation unit 11 for adjusting the intensity and phase of the light emitted by the light emitting module 10. , luminous field type, etc., so as to be used in different materials or liquids, and the light emitting module 10 can be a wide-band spectrum light source such as LED or neon (Ne) lamp, or a narrow-spectrum light source such as a laser diode (Laser Diode) , and the optical modulation unit 11 can be a pinhole (Pin Hole), a photointerrupter, a frequency multiplier (Etalon), a grating (Grating), or an optical amplifier (Amplifier).

[0052] The light receiving module 20 has an output end, and the light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com