Instant thick film heater

A thick-film heater, instant heating technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problem of low space utilization in the heater shell, easy damage to the solder at the outer contact point, and utilization of thermal efficiency. Low efficiency and other problems, to achieve the effect of shortening the heating time, optimizing the installation process, and improving the heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

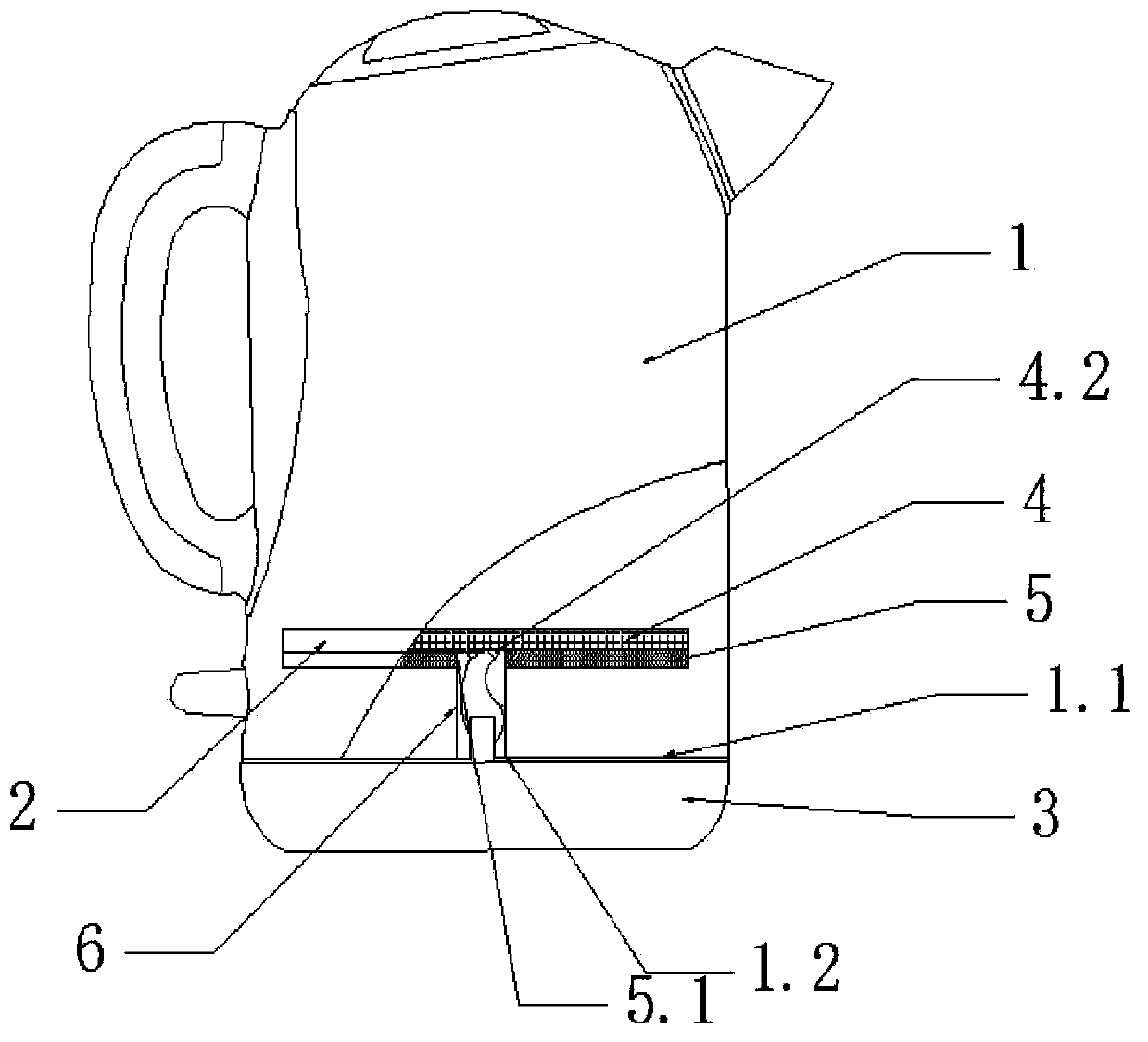

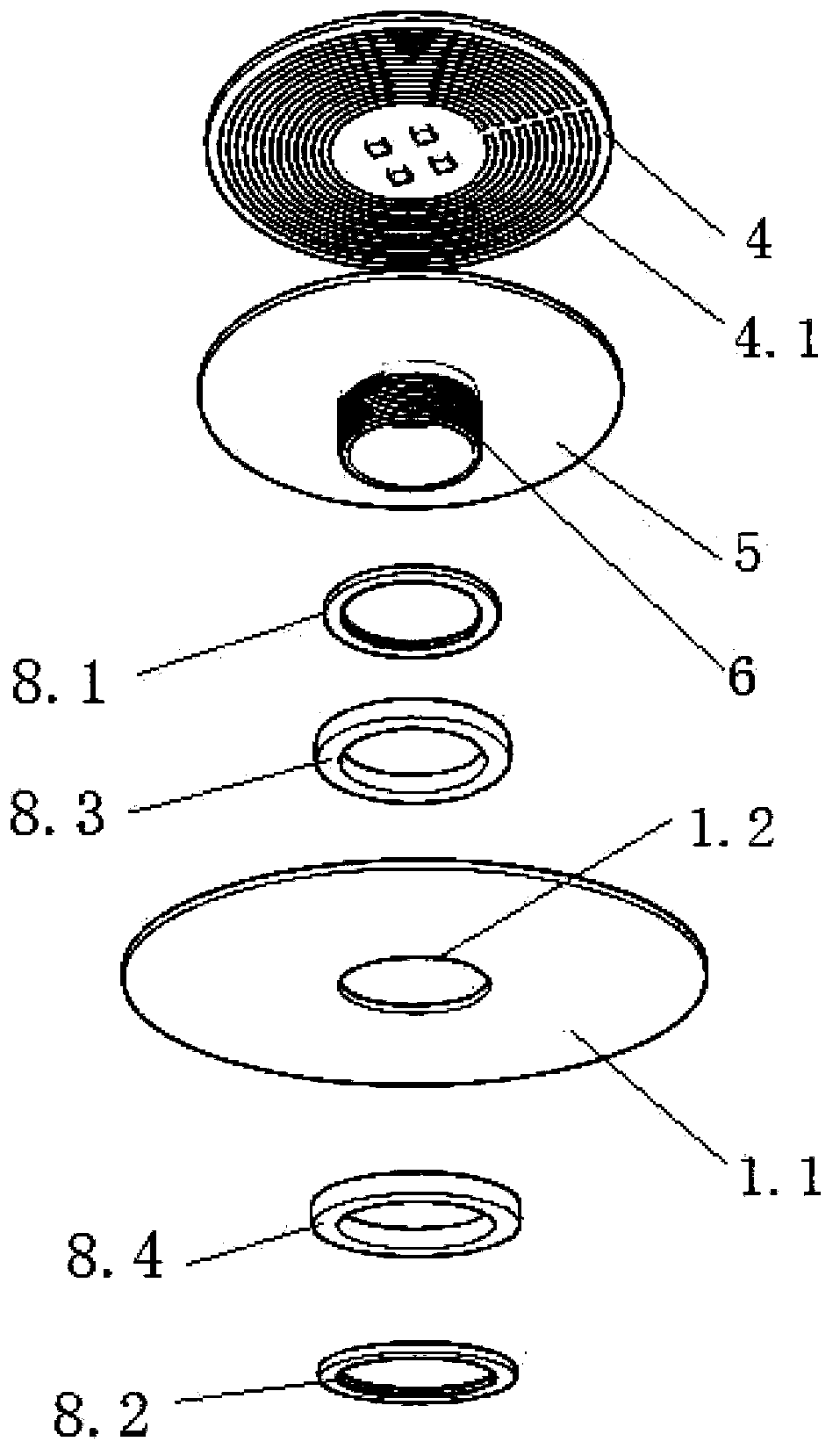

[0025] refer to figure 1 , the instant thick-film heater of the present embodiment includes a container for storing water and a thick-film heater 2 installed in the container. The container is the kettle body 1 of an electric kettle, and the material of the container can be selected from stainless steel and aluminum alloy. Material manufacturing can also be molded with food-grade organic polymer materials, mainly to achieve direct connection or indirect connection with the thick film heater 2 . The kettle body 1 includes the bottom plate 1.1 of the kettle body, and the thick film heater 2 is installed on the cross section of the kettle body 1. It is matched with the kettle body 1, and is also provided with a power supply base 3, and a temperature sensing tube and an anti-dry device are arranged in the container , The temperature sensing tube, the anti-dry heating device and the thick film heater 2 are all installed in the kettle body 1, and the thick film heater 2 is electrica...

Embodiment 2

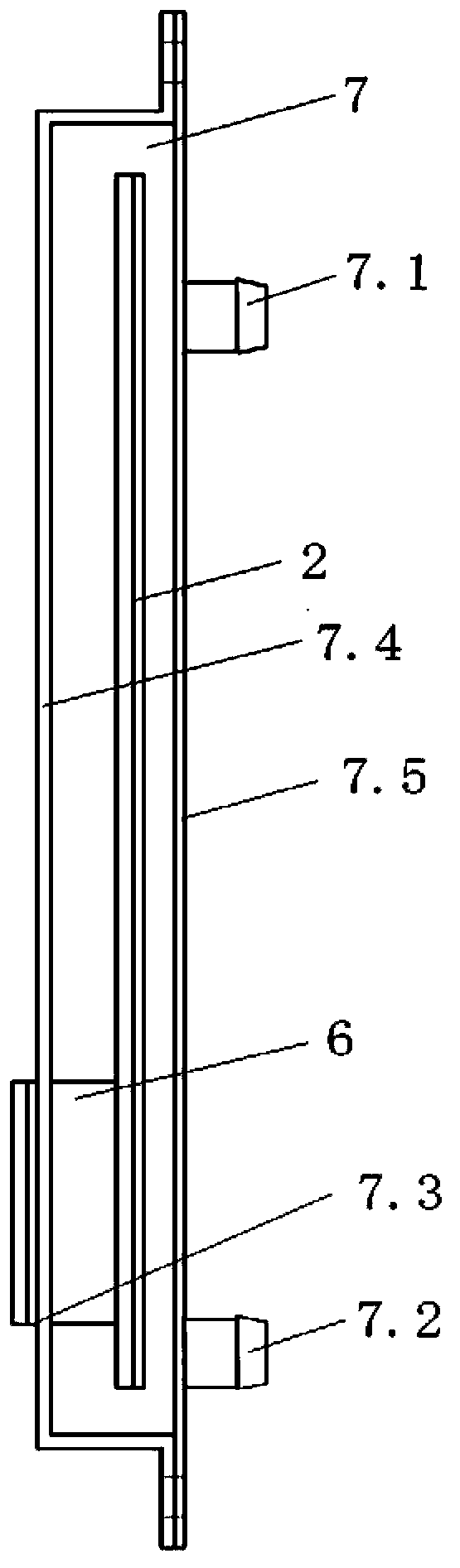

[0031] refer to Figure 3-4 , the instant thick-film heater of the present embodiment is a water heater or a water dispenser, wherein the container is the outer wall 7 of the water heater or water dispenser, and the material of the container can be made of stainless steel or aluminum alloy, or can be made of food-grade organic polymer materials Molding manufacturing mainly depends on realizing the direct connection or indirect connection with the thick film heater 2 . The outer wall 7 is assembled by the front plate 7.4 and the back plate 7.5 to form a closed cavity, which is generally in the shape of a regular cuboid, but it can also be tightened on the container at the end of the hot water outlet as required, so that the upper part of the container The volume of the part is smaller than that of the lower part, which is similar to a triangular shape. If the upper part of the container is tightened, it will help the water heater or drinking fountain to quickly produce hot wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com