Composite sandwich structure cable bridge

A technology of composite materials and cable trays, applied in the direction of pipeline supports, electrical components, pipes/pipe joints/pipe fittings, etc., can solve the problems of easy corrosion and cost increase, and achieve the effects of low cost, high production efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

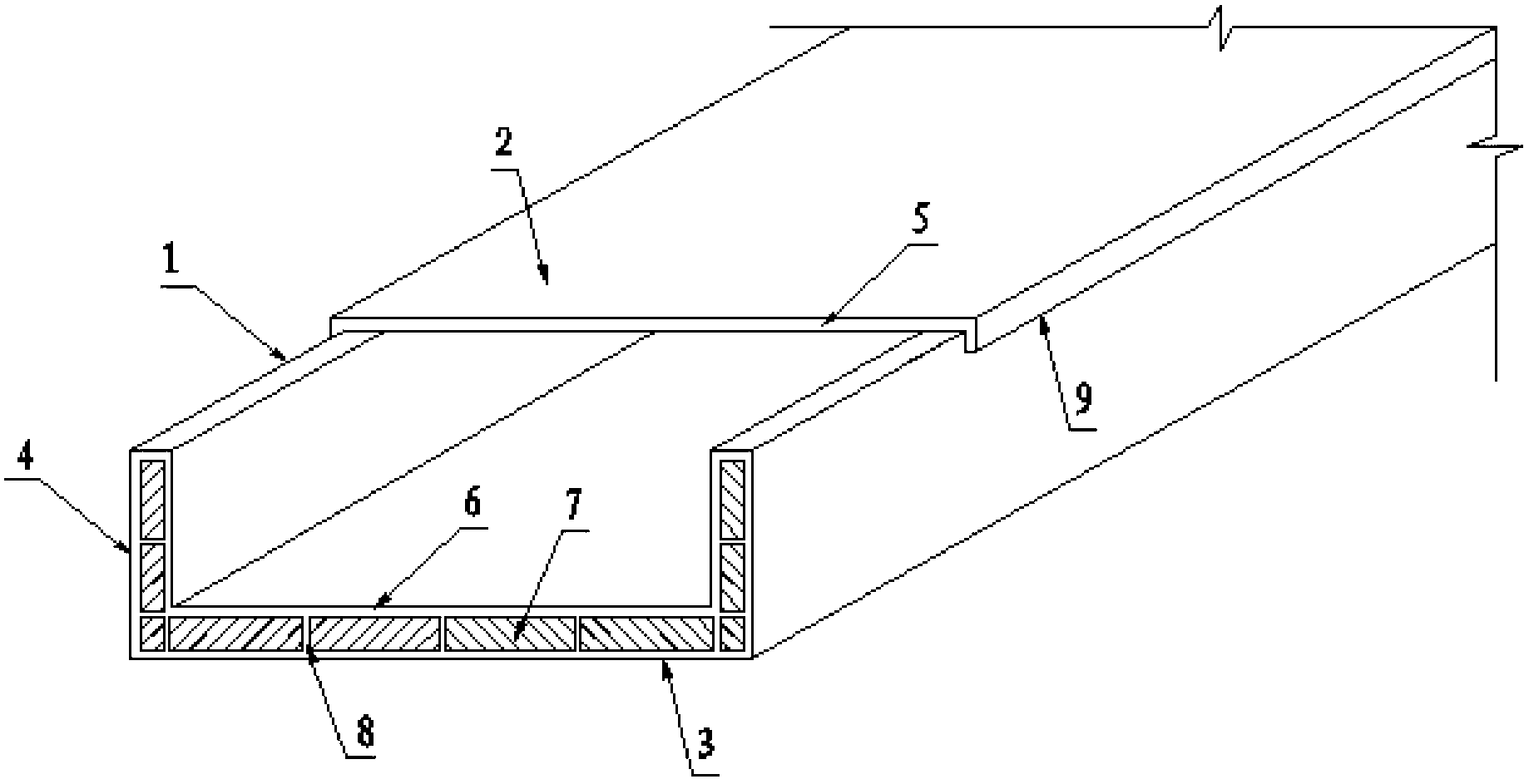

[0043] Such as Figure 8 As shown, a composite material sandwich structure cable tray, the structure is composed of a groove unit 1 and a cover unit 2. The trough unit 1 includes a side plate 4 and a bottom plate 3. The trough unit 1 is a sandwich entity composed of a composite material surface layer 6 and a sandwich material 7 filled in the surface layer and a lattice web 8. The composite material surface layer 6 It is a solid shell made of glass fiber and vinyl resin cured at high temperature; the sandwich filling material 7 in the composite surface layer 6 is made of Paulownia wood core material, and there is a lattice web 8 between the Paulownia wood core materials. The web 8 is formed by laying biaxial glass fiber cloth along multiple layers and directions, and then adopts a pultrusion process to integrally form the groove unit 1 . After the trough unit 1 is prepared in the factory, the cover unit 2 is directly pultruded by adding a layer of glass felt on the upper and l...

Embodiment 2

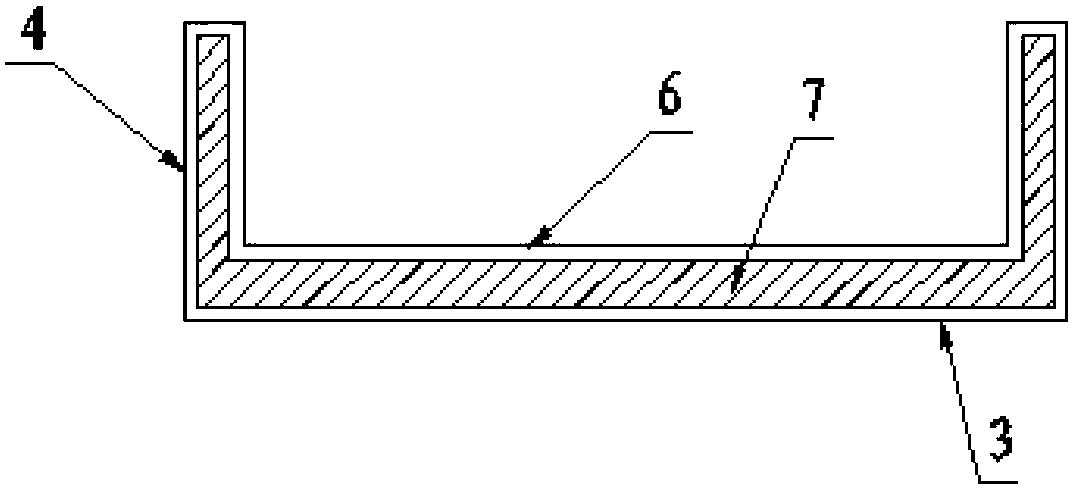

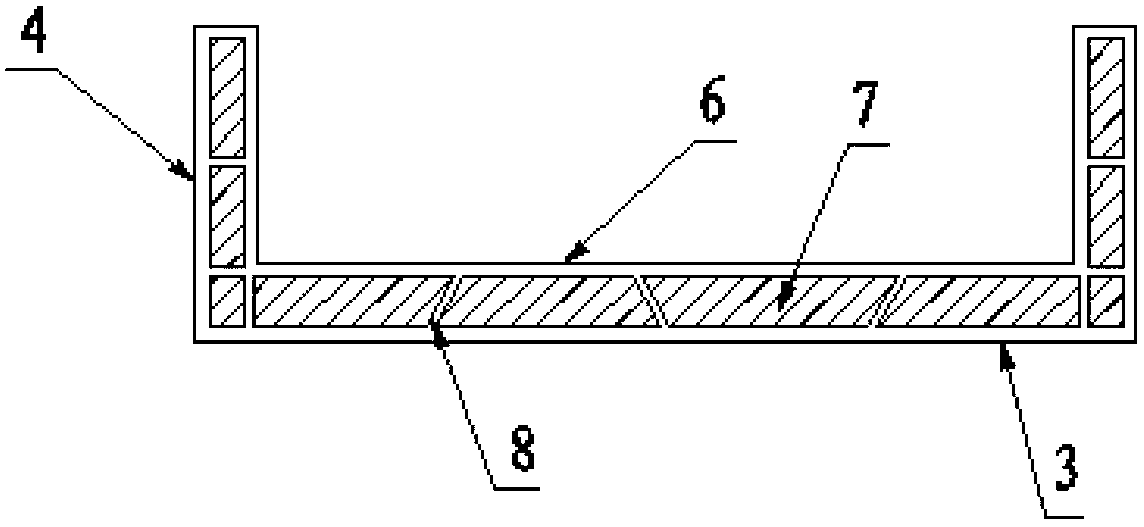

[0045] Such as Figure 9As shown, a cable bridge with a composite material sandwich structure, the bridge adopts a groove unit 1 with a bottom plate 3 as a sandwich structure and a side plate 4 as a laminated plate form, which can be used for heavy-duty pipeline transportation devices for new subways, bridges and tunnel structures. The structure is composed of a groove unit 1 , a cover unit 2 and a fastener 10 . The trough unit 1 is composed of a side plate 4 and a bottom plate 3. The side plate 4 is composed of a composite material surface layer 6, which is a solid shell made of glass fiber and vinyl resin cured at high temperature. The shape of the side plate 4 is an inverted "L" , Punch holes on the upper end for later assembly. The bottom plate 3 is composed of a composite material surface layer 6 and a sandwich material 7 filled in the surface layer, without lattice webs. The groove unit 1 is integrally formed by a pultrusion process. After the trough unit 1 is prepare...

Embodiment 3

[0047] Such as Figure 10 As shown, a cable tray with a composite material sandwich structure, the bridge uses a grooved unit 1 bottom plate 3 is a hollow shell structure with ribs and the side plate 4 is a laminated plate form, which can be used for heavy-duty pipelines in newly built subways, bridges and tunnel structures The delivery device can also be used to replace damaged bridge sections. The structure consists of a trough unit 1 and a cover unit 2. The trough unit 1 is composed of a side plate 4 and a bottom plate 3. The side plate 4 is a solid shell composed of a composite material surface layer 6 cured by glass fiber and vinyl high-temperature resin. Its shape is an inverted "I" shape, and the bottom plate 3 is a ribbed hollow shell structure, which is composed of a diagonal rib lattice web 8 and a composite material surface layer 6 . The groove unit 1 is integrally formed by glass fiber and vinyl resin solidified at high temperature through a pultrusion process. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com