A transmission nut with high transmission precision

A technology of transmission nut and transmission accuracy, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of increased cost, inconvenient assembly, easy damage of transmission nut, etc., and achieves meticulous position movement and structural design saving. , the effect of easy installation and connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

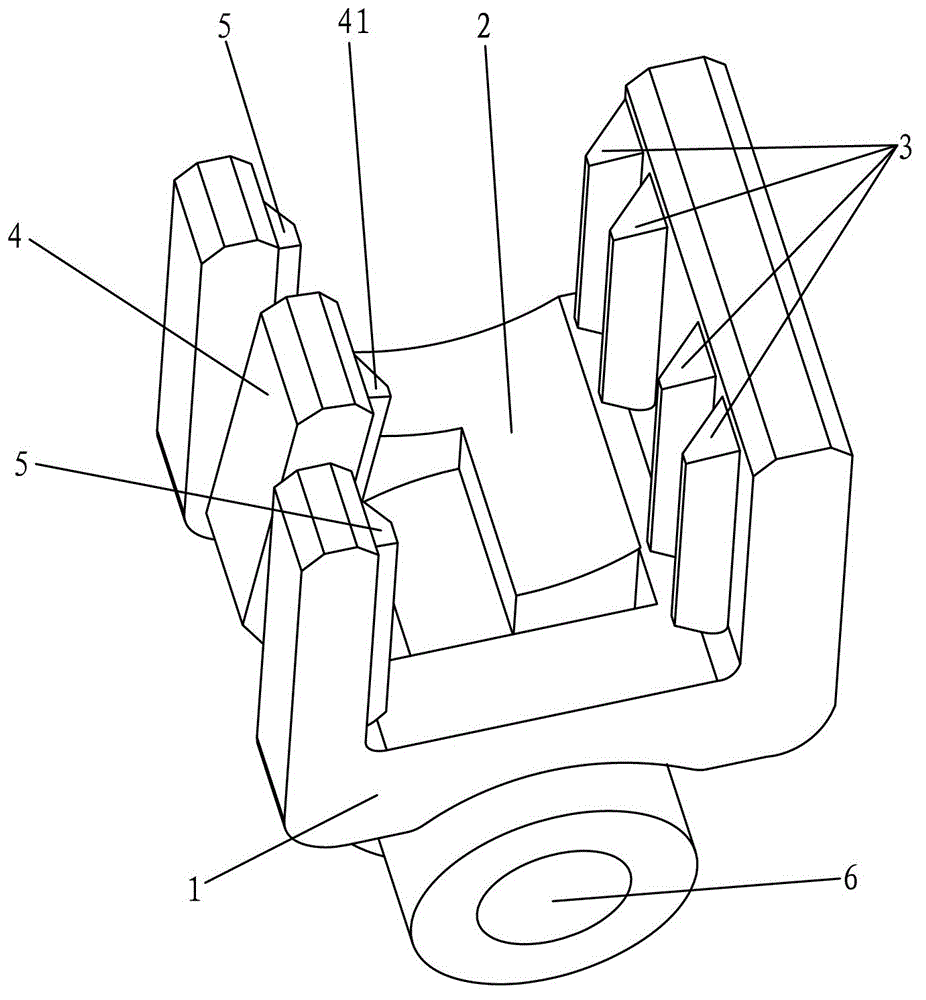

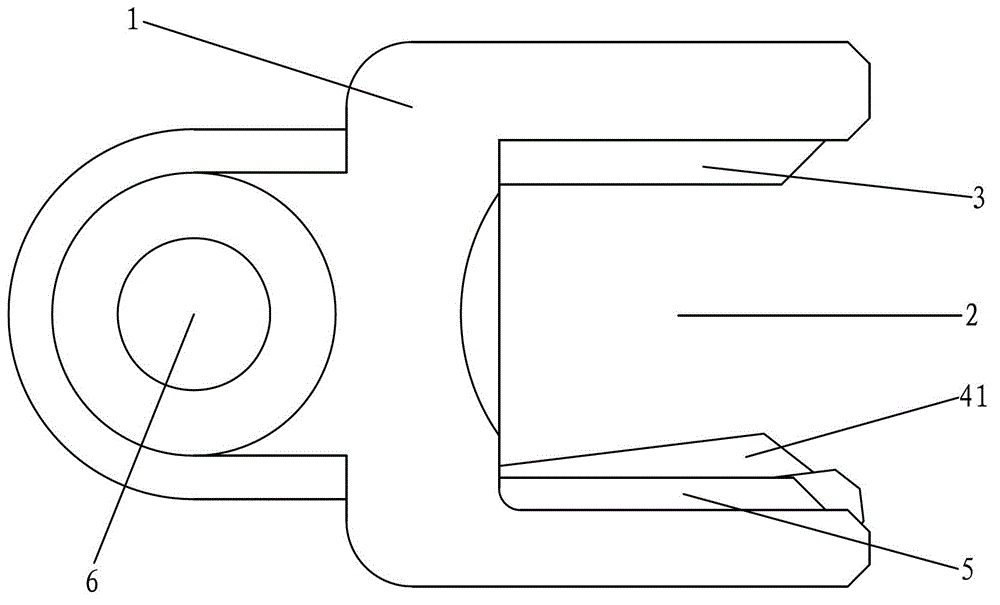

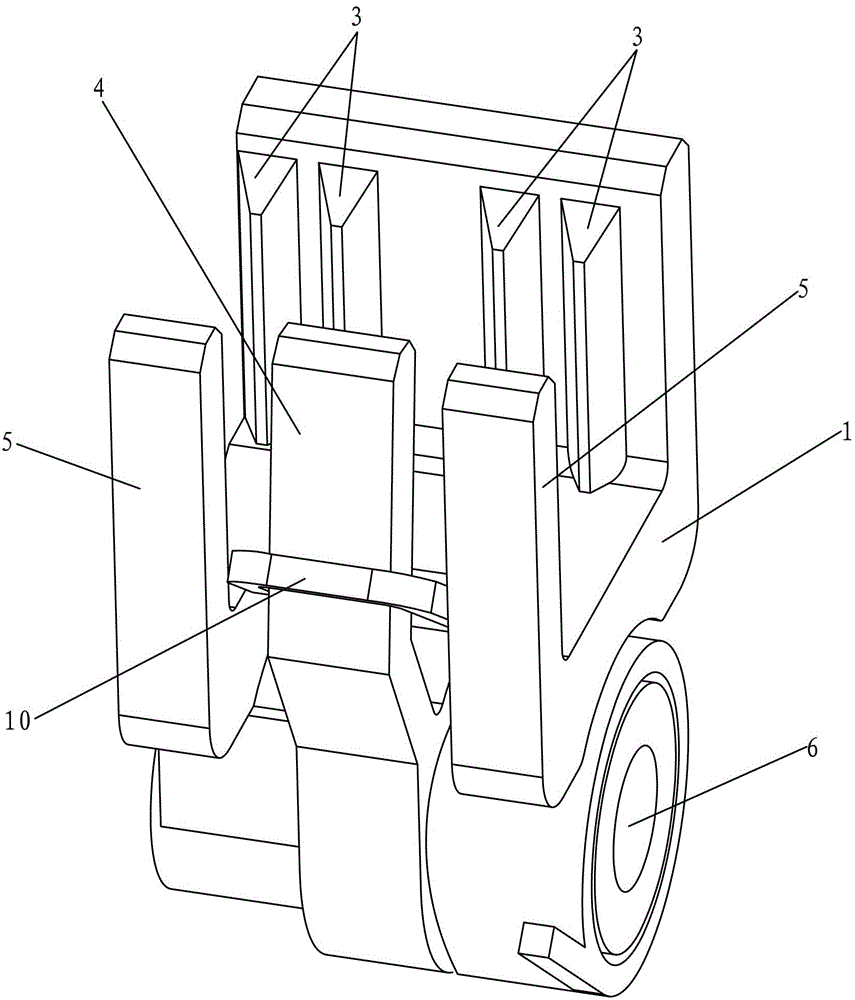

[0022] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] The present invention is a transmission nut with high transmission precision, which is made of plastic material, and includes a nut body 1. The nut body 1 is provided with a U-shaped opening 2 for cooperating with a transmission screw 8. One side of the U-shaped opening 2 There is a main thread 3 for cooperating with the screw thread on the drive screw 8 , and the other side of the U-shaped opening 2 is an elastic pressing block 4 .

[0024] The elastic pressing block 4 is provided with an elastic thread 41 for cooperating with the thread on the drive screw 8 .

[0025] The two sides of the elastic pressing block 4 are provided with auxiliary screw teeth 5 for correction, and the auxiliary screw teeth 5 and the elastic screw teeth 41 are not on the same plane.

[0026] A spring leaf 10 for pressing the elastic pressing block 4 is provided on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com