Shallow mud foundation treatment method

A technology for silt foundation and treatment method, which is applied in basic structure engineering, soil protection, construction, etc., can solve the problems of large deformation of drainage board, long construction period, and large use of sea sand, etc., to achieve convenient laying, shorten construction period, and facilitate mechanization. construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with example

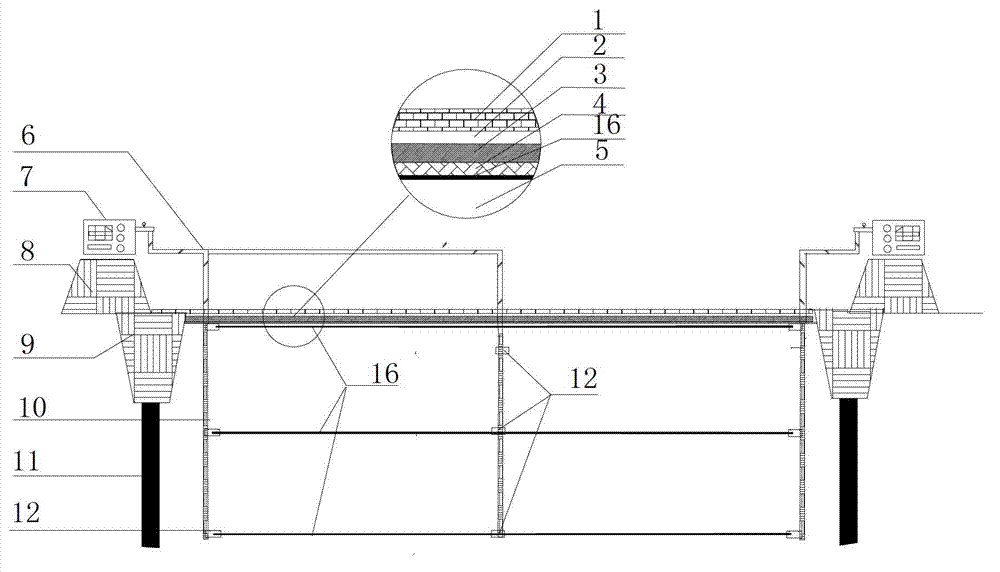

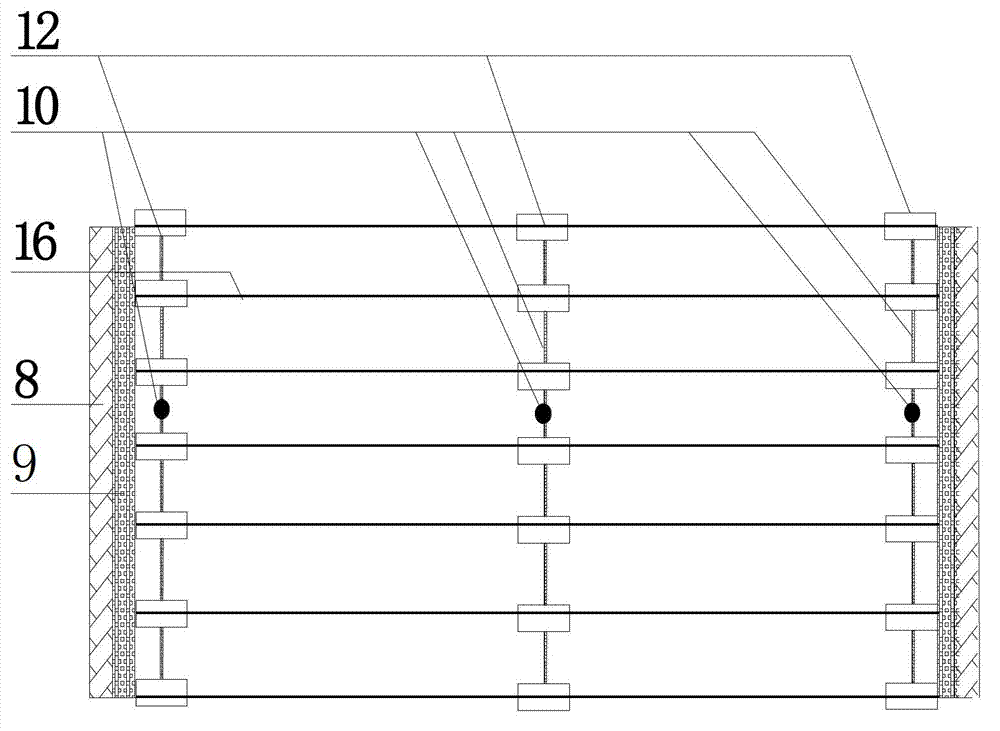

[0021] Such as figure 1 and figure 2 Shown, the present invention, concrete implementation method step is as follows:

[0022] Put up floating bridge: build floating bridge 8 with bamboo pole, steel pipe in conjunction with lightweight material, floating bridge can be used as construction access road, can place vacuum equipment simultaneously.

[0023] Zoning: along the periphery of the pontoon, color steel plates are used to divide the area, and plastic films are laid on the inner side of the color steel plates to form water storage enclosures.

[0024] Seal wall 11 (seal ditch 9) construction.

[0025] Water storage on the site: inject water into the divided area with a water pump, and the water depth should be such that the floating raft can float and move during construction.

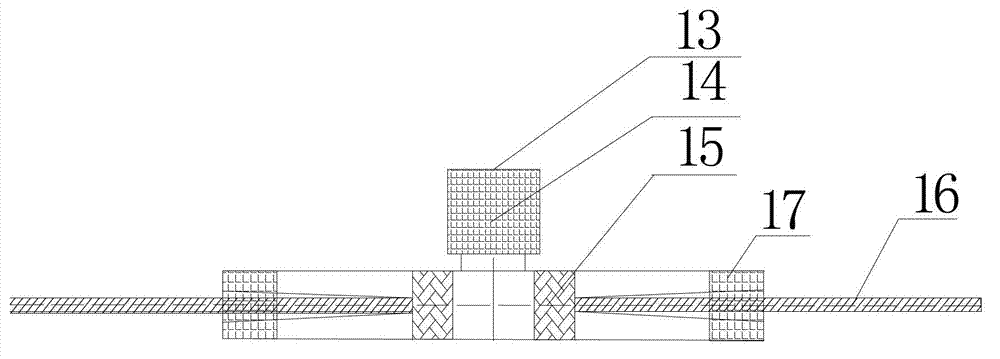

[0026] Laying of drainage boards: use floating rafts to lay plastic drainage boards 16 from bottom to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com