Method for preparing L-glutamic acid by fermentation

A technology of glutamic acid and hydrochloride, applied in the biological field, can solve problems such as inability to be directly applied, restricted use, etc., to achieve great application value, increase growth rate and acid production rate, and increase the effect of oxygen consumption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

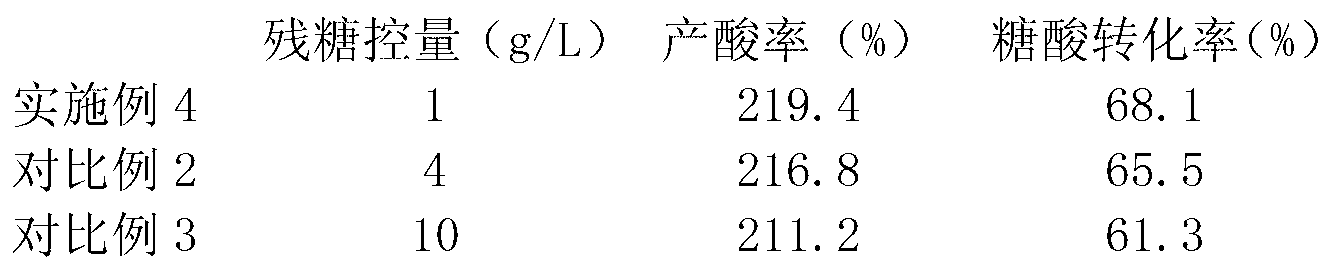

Examples

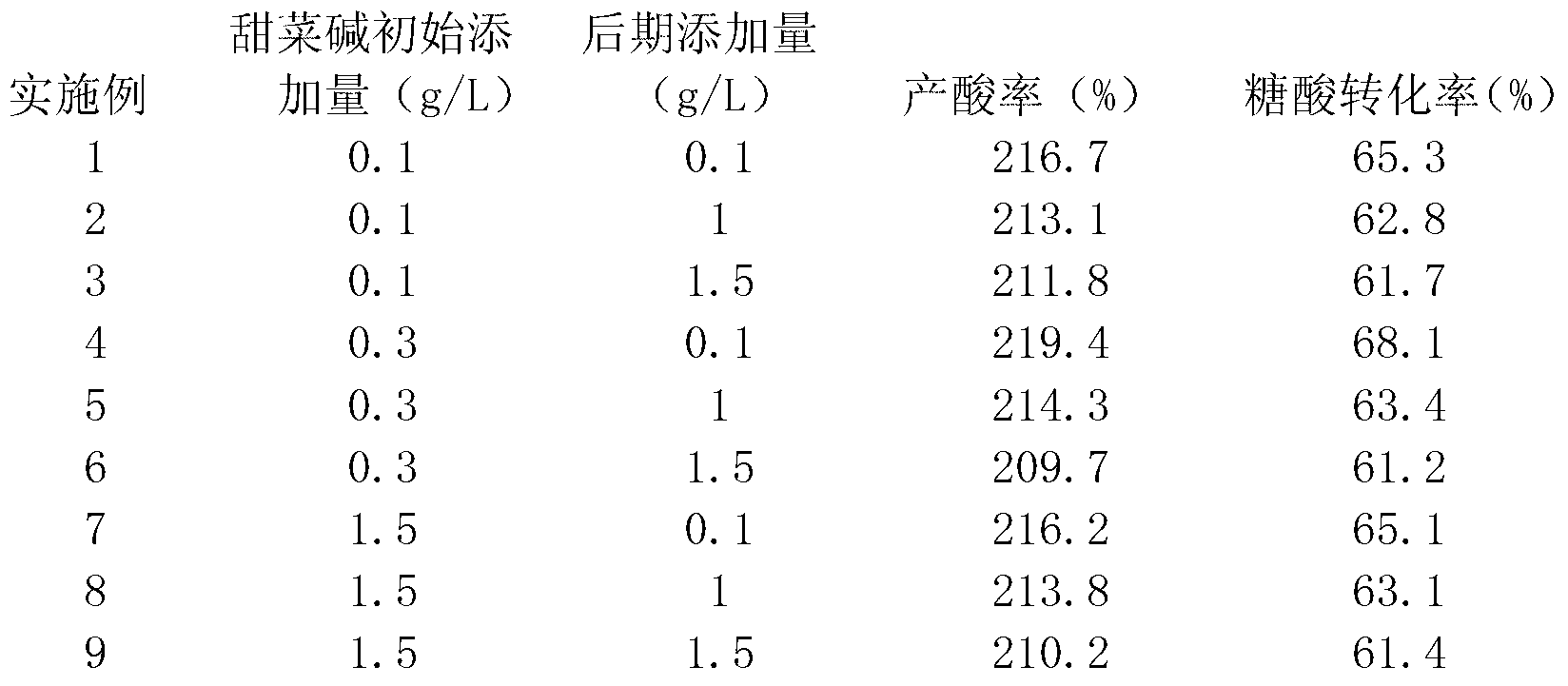

Embodiment 1

[0021] The strain used is a temperature-sensitive glutamate producer: Brevibacterium glutamicum

[0022] Seed medium ( / L):

[0023] Glucose 15g, corn steep liquor 20g, K2HPO 4 3g, MgSO4 7H 2 O1g, VB1200μg / L, DL-methionine 50μg / L, FeSO 4 ·7H 2 O, MnSO 4 ·H 2 O each 2mg / L, urea 0.55 (divided), pH 7.0-7.2, sterilized at 121°C for 15 minutes;

[0024] Seed culture method: Wash the slant bacteria with 10ml of sterile water, transfer to a 5000mL seed bottle with 1200mL of seed medium, culture at 32°C, 160rpm, and shake for 14-16 hours;

[0025] Fermentation medium ( / L):

[0026] Glucose 20g, corn steep liquor 20g, betaine hydrochloride 0.1g, K 2 HPO 4 7.5g, MgSO 4 ·7H 2 O1.5g, VB1200μg / L, VH600μg / L, FeSO 4 ·7H 2 O, MnSO 4 ·H 2 O each 30mg / L, urea 0.55 (divided), pH 7.0-7.2, sterilized at 121°C for 15 minutes;

[0027] Fermentation culture method: according to the inoculum amount of 12%, put all the seed liquid into a 15L fully automatic control fermenter containing f...

Embodiment 2

[0031] The strain used is a temperature-sensitive glutamic acid-producing bacterium: Corynebacterium glutamicum; when the conversion temperature reaches 37° C., 1 g / L betaine hydrochloride is added at the same time; other conditions and cultivation methods are the same as in Example 1. When the tank was released, the output of L-glutamic acid was 213.1g / L, and the sugar-acid conversion rate was 62.8%.

Embodiment 3

[0033]The bacterial strain adopted is a temperature-sensitive glutamic acid-producing bacterium: Brevibacterium glutamicum; when the conversion temperature reached 37°C, 1.5g / L of betaine hydrochloride was added simultaneously; other conditions and cultivation methods were the same as in Example 1 . When put into the tank, the output of L-glutamic acid was 211.8g / L, and the sugar-acid conversion rate was 61.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com