Silk-screen printing ink and application thereof

A technology of screen printing ink and weight percentage, applied in screen printing ink and its application field, can solve problems such as degumming, breakage, light leakage, etc., achieve good leveling, excellent performance, and meet the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

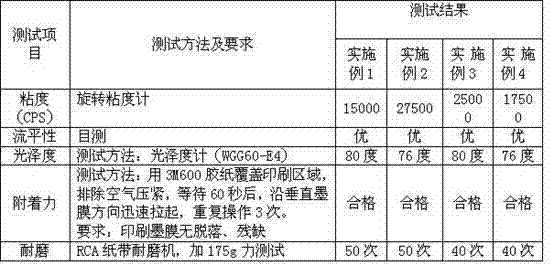

Examples

preparation example Construction

[0043] The preparation method of the TPU material screen printing ink is as follows: mix PU resin, ketone solvents, benzene solvents, and additives evenly, stir at high speed until completely dissolved, and then filter through 200-mesh gauze to obtain the finished product.

[0044] The TPU material screen printing ink, by weight percentage, can also include the following components:

[0045] Pigment 10-20.

[0046] Described TPU material screen printing ink, wherein, by weight percentage, is most preferably made up of following components:

[0047] PU resin 35;

[0048] Pigment 10;

[0049] Ketone solvents 36;

[0051] Auxiliary 4.

[0052] The preparation method of the TPU material screen printing ink is as follows: PU resin, ketone solvent, and benzene solvent are fully mixed and then stirred evenly at high speed, then adding additives and pigments, grinding 5 times by a three-roller machine, and stirring evenly at high speed.

[0053] Spec...

Embodiment 1

[0062] 35 parts (weight) of PU resin, 41 parts (weight) of ketone solvent, 20 parts (weight) of benzene solvent, 4 parts (weight) of additives (including 1 part of defoamer, 2 parts of thickener, and 1 part of catalyst ) after mixing evenly, stir at high speed until completely dissolved, and then filter through 200-mesh gauze to get the finished product.

Embodiment 2

[0064] 35 parts (weight) of PU resin, 36 parts (weight) of ketone solvent, 15 parts (weight) of benzene solvent, after fully mixing, stir at high speed, then add 2 parts (weight) of dispersant, 10 parts (weight) of pigment, thickener 1 part (by weight), grind 5 times with a three-roller machine, add 1 part (by weight) of defoamer, and stir evenly at high speed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com