Height measurement control system of cutting machine and working process of height measurement control system

A control system and cutting machine technology, applied in metal processing and other directions, can solve the problems of no signal, dangerous economy, unstable signal, etc., and achieve the effect of preventing cutting of the worktable and the blade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0016] The technical scheme of concrete implementation of the present invention is:

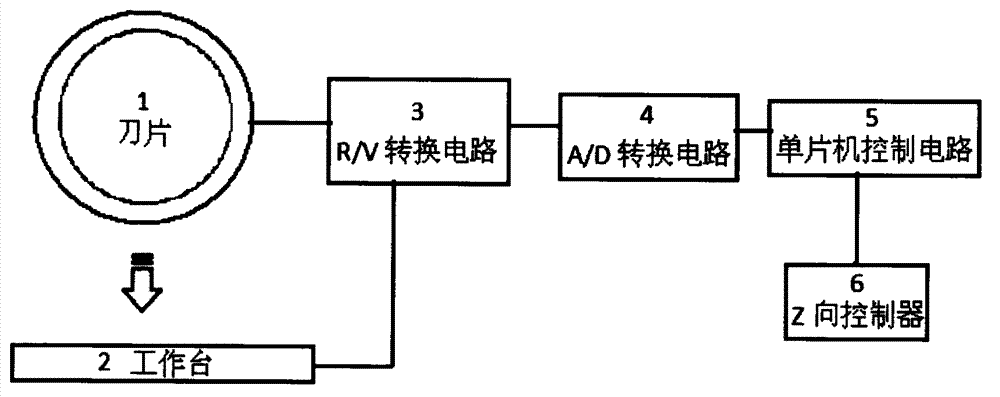

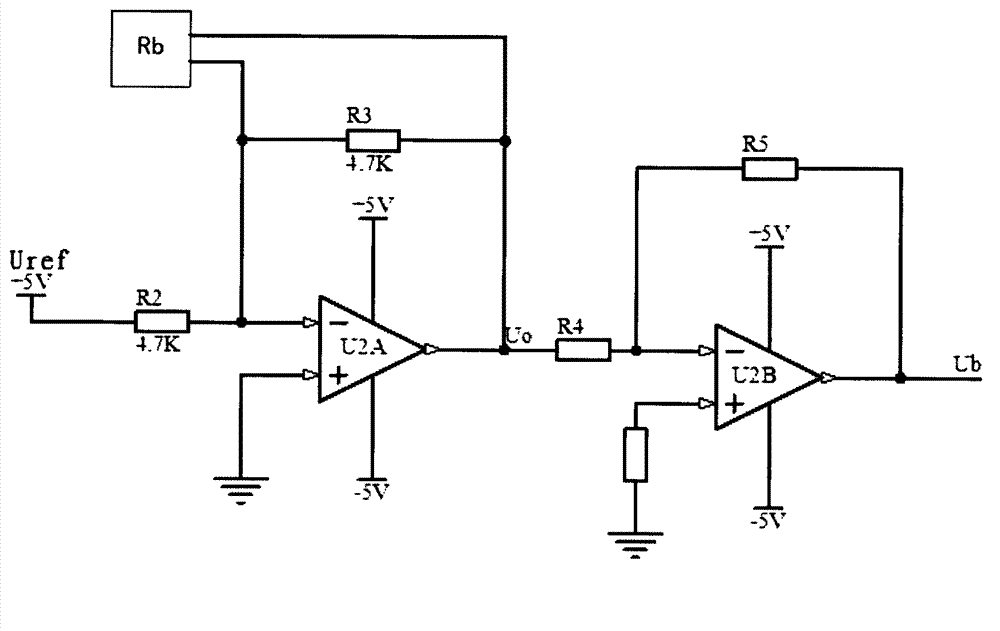

[0017] like figure 1 As shown, a cutting machine height measurement control system includes a blade 1, a workbench 2, an R / V conversion circuit 3, an A / D conversion circuit 4, a single-chip microcomputer control circuit 5 and a Z-direction controller 6; the R / V conversion circuit 3 includes two stages of inverse proportional operational amplifier circuits, each of which contains an operational amplifier; the voltage output terminal of the first stage inverting proportional operational amplifier circuit is connected to the voltage of the second stage inverting proportional...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com