Shirt fabric

A technology for fabrics and shirts, applied in the field of shirt fabrics, can solve the problems of easy dyeing, poor air permeability, wear resistance, heat resistance, moisture absorption, poor air permeability, etc., and achieve the effect of wearing comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

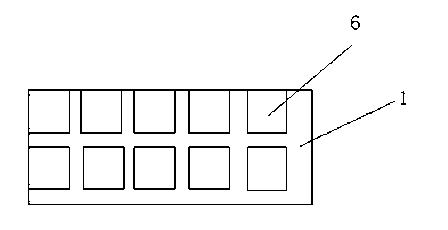

[0016] figure 1 A specific embodiment of a shirting fabric with the structure of the present invention is shown: the shirting fabric includes a fabric 1 body formed by interweaving warp yarns 2 and weft yarns 3, the warp yarns 2 and weft yarns 3 are made of cotton linter fibers 4, and the warp yarns 2 and weft yarns are 3 is added with flax fiber 5, which accounts for 30%-35% of the mass percentage of warp yarn 2 and weft yarn 3 respectively. The surface fabric of fabric 1 body is dyed, and several grids 6 are regularly distributed.

[0017] The beneficial effects of adopting the above technical scheme are: the shirt fabric of the structure of the invention is interwoven by warp and weft yarns, the warp and weft yarns are made of cotton linter fibers, flax fibers are added in the warp and weft yarns, and the shirt of pure cotton fabric is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com