Getter chamber structure of front-end Dewar flask for superconducting receiver

A getter and receiver technology, applied in electrical components, transmission systems, etc., can solve the problems of inability to activate the getter, reduce the reliability of the system, increase the number of series components, etc., to improve reliability and environmental adaptability, improve The effect of vacuum life and reliability, easy operation and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

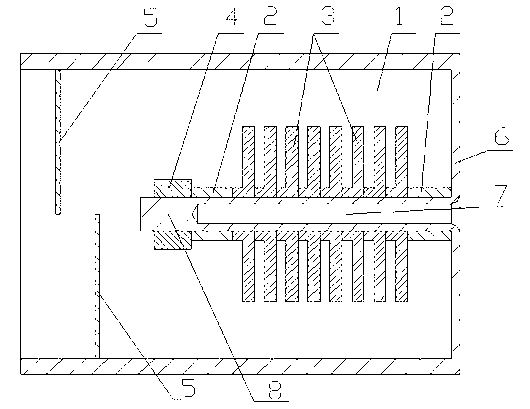

[0017] like figure 1 , figure 2 As shown, the structure of the getter chamber of the Dewar for the front end of the superconducting receiver of the present invention includes a cylindrical getter chamber 1 composed of a stainless steel getter chamber wall, and the upper wall 6 of the getter chamber 1 is directed toward A cavity 7 for installing a heating rod is formed by the depression in the getter chamber, the lower end is provided with a cover 8 and the upper end is open; a plurality of getters 3 are arranged around the upper wall of the getter chamber 1, which is open at the upper end. A heat insulating tube 2 made of titanium alloy or high temperature resistant ceramic material is arranged between a plurality of getters 3 and the upper wall of the getter chamber which is not recessed. A heat insulating tube 2 made of titanium alloy or high temperature-resistant ceramic material is also arranged between the getters 3; each getter 3 is a disc-shaped porous sintered getter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com