Heat insulation type spontaneous combustion testing equipment

A test equipment, adiabatic technology, applied in the field of coal sample spontaneous combustion test equipment, to achieve the effects of reliable process, simple and compact structure, and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

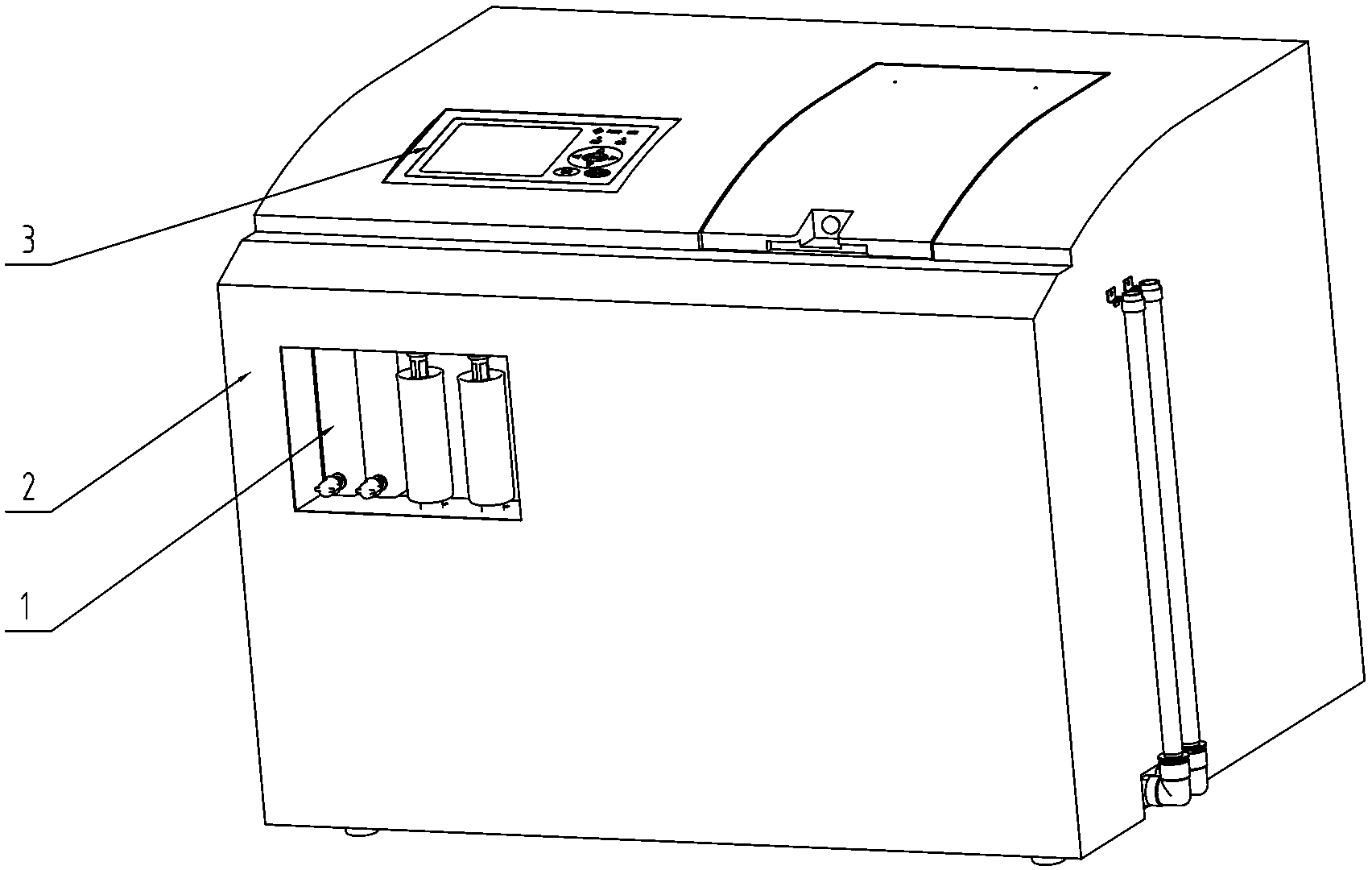

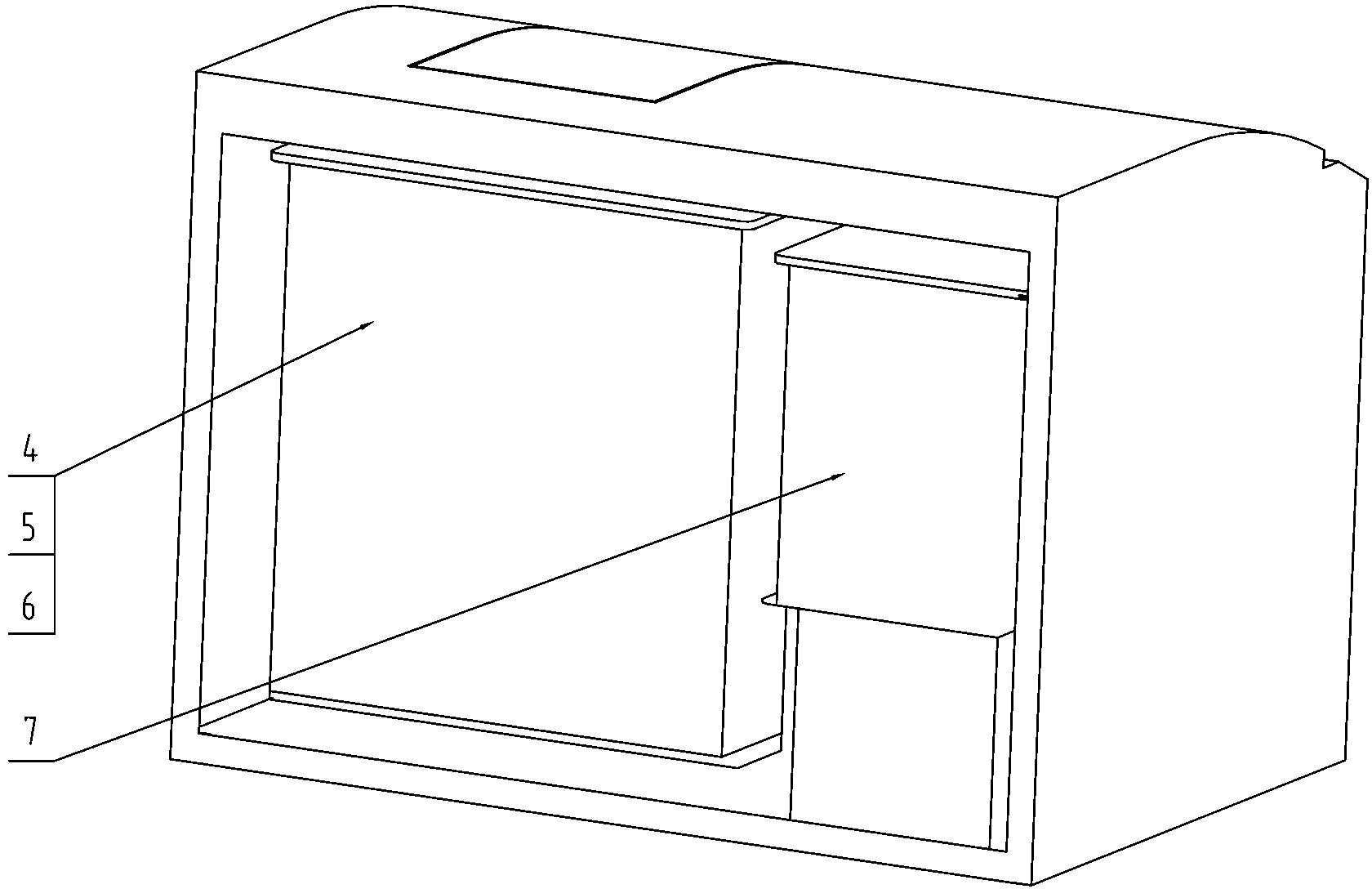

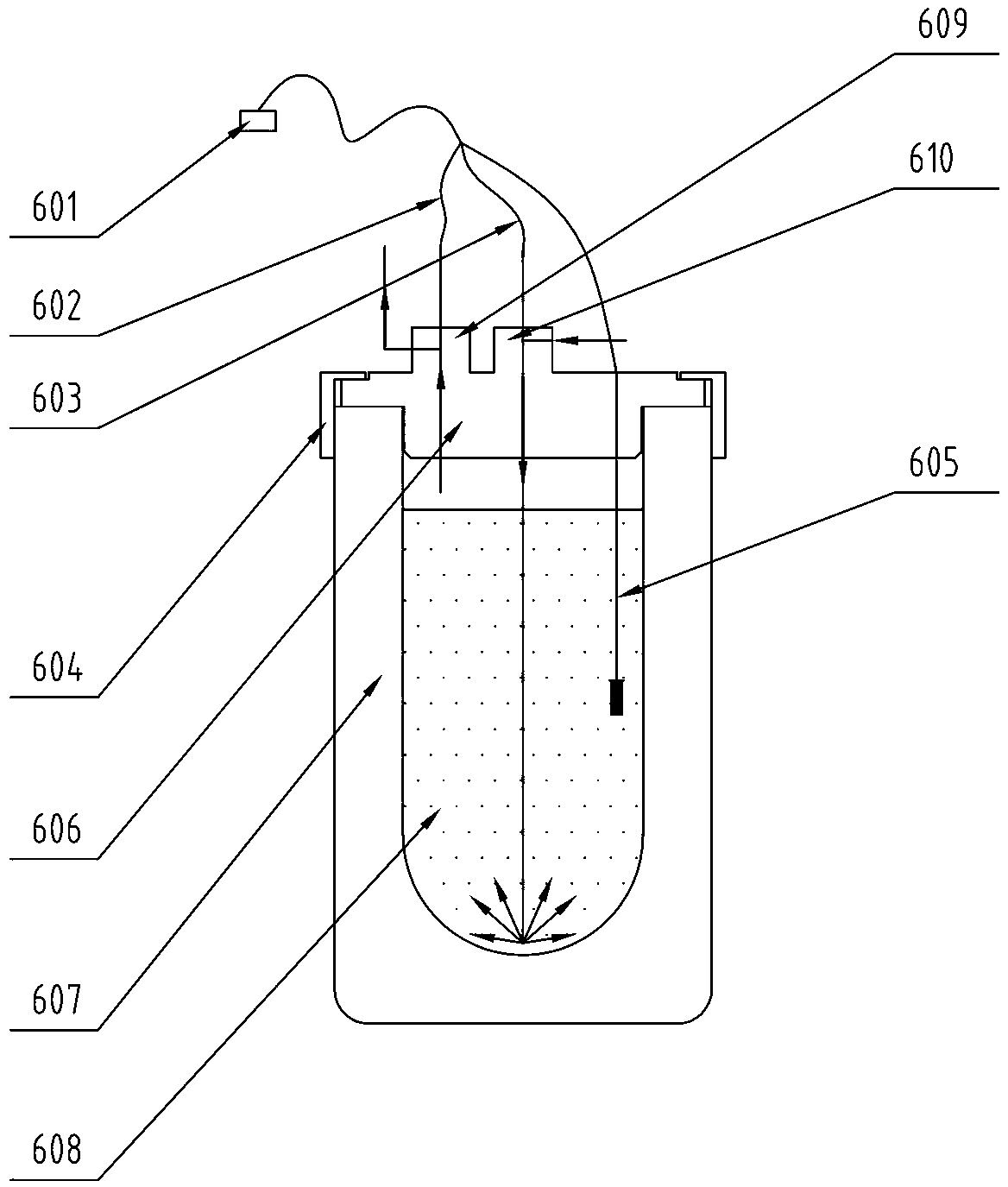

[0024] Such as figure 1 and figure 2 As shown, the adiabatic spontaneous combustion test equipment of the present invention includes a water bath assembly 4, a heating assembly 7, a preheating assembly 5, a reactor 6, a gas path system 1, a control system 3 and an outer frame 2, and the reactor 6 is used to contain the For the detected coal sample, the reactor 6 is placed in the water bath assembly 4, and the heating assembly 7 is used to heat the water environment in the water bath assembly 4, so that the temperature difference between the temperature of the water in the water bath assembly 4 and the temperature of the coal sample in the reactor 6 is maintained. within a very small range. The reactor 6 communicates with the external gas supply part through the gas circuit system 1, and the external gas supply part is an oxygen sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com