Blended pulverized coal combustion control device and method

A technology of pulverized coal combustion and control device, which is applied in combustion method, block/powder fuel preparation, combustion chamber, etc., can solve the center deviation of furnace flame, combustion characteristics, combustion optimization control technology and its device. Problems such as few coal types, poor adaptability to changing coal types, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

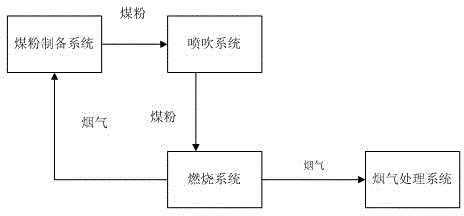

[0043] Example 1: The blended pulverized coal combustion control device includes a pulverized coal preparation system, an injection system, a combustion system, and a flue gas treatment system. The mixed pulverized coal is processed by the pulverized coal preparation system and then enters the combustion system from the injection system for blending combustion. The tail gas discharged after combustion is treated and discharged through the flue gas treatment system;

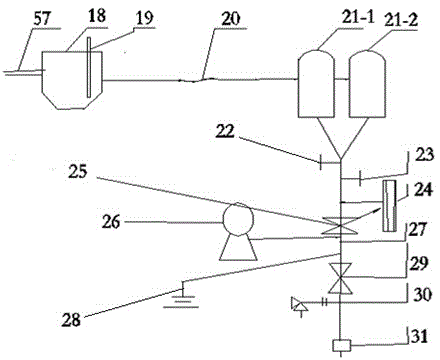

[0044] Wherein the pulverized coal preparation system includes a raw coal bunker 1, a loader 2, a raw coal meter 3, a belt conveyor 4, a coal mixing initial hopper 5, a disc feeder 6, a drying furnace 7, a steel ball coal mill 9, Primary fan 10, coarse powder separator 11, primary fine powder separator 12, secondary fine powder separator 13, circulating fan 14, bag filter 15, screw conveyor 16, impeller feeder 17, coal powder mixing bin 18. The belt conveyor 4 is connected through the raw coal metering 3, the lo...

Embodiment 2

[0054] Example 2 : The device structure of this embodiment is the same as that of Embodiment 1, the difference lies in the steel ball coal mill specification model Ф2700×4500, output: 12~90 (t / h), output granularity: 0.074~0.4 (mm), disc feeding Machine specification model 1000, feeding capacity 4.2 ~ 22 (m 2 / h). The conveying pipeline is made of steel, and the mixed coal pulverized coal has an appropriate particle size and is evenly mixed.

[0055] When using the device of this embodiment, the mixed coal raw material is prepared. The mixed coal raw material includes lignite with a mass percentage of 20%, bituminous coal with a mass percentage of 45%, and anthracite with a mass percentage of 35%. (The coal supply time is 620s, the delayed combustion time is 80s, and the furnace switching time is 20s). After drying in the drying furnace of the pulverized coal preparation system, the mixed coal raw material has a moisture content of 5%. The particle size is 100μm, and the t...

Embodiment 3

[0060] Example 3: The device structure of this embodiment is the same as that of Embodiment 1, except that the steel ball coal mill is GZM2135Ф2100×3500, output: 4.5-33 (t / h), and output granularity: 0.074-0.6 (mm). Disc feeder specification model 1000, feeding capacity 4.2 ~ 22 (m 2 / h), the conveying pipeline is made of steel, and the mixed coal powder has an appropriate particle size and is evenly mixed.

[0061] When using the device of this embodiment, the mixed coal raw material is prepared. The mixed coal raw material includes lignite with a mass percentage of 10%, bituminous coal with a mass percentage of 80%, and anthracite with a mass percentage of 10%. (The coal supply time is 550s, the delayed combustion time is 80s, and the furnace switching time is 20s). After drying in the drying furnace of the pulverized coal preparation system, the mixed coal raw material has a moisture content of 4%. The particle size is 60 μm, and the temperature is ≤70°C; the mixed coal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com