Rear smoke channel of biomass boiler and biomass boiler

A biomass boiler and tail flue technology, which is applied in the direction of combustion product treatment, combustion method, exhaust gas device, etc., can solve the problems of reducing boiler output, easy ash accumulation, safety accidents, etc., and achieve the effect of solving ash accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

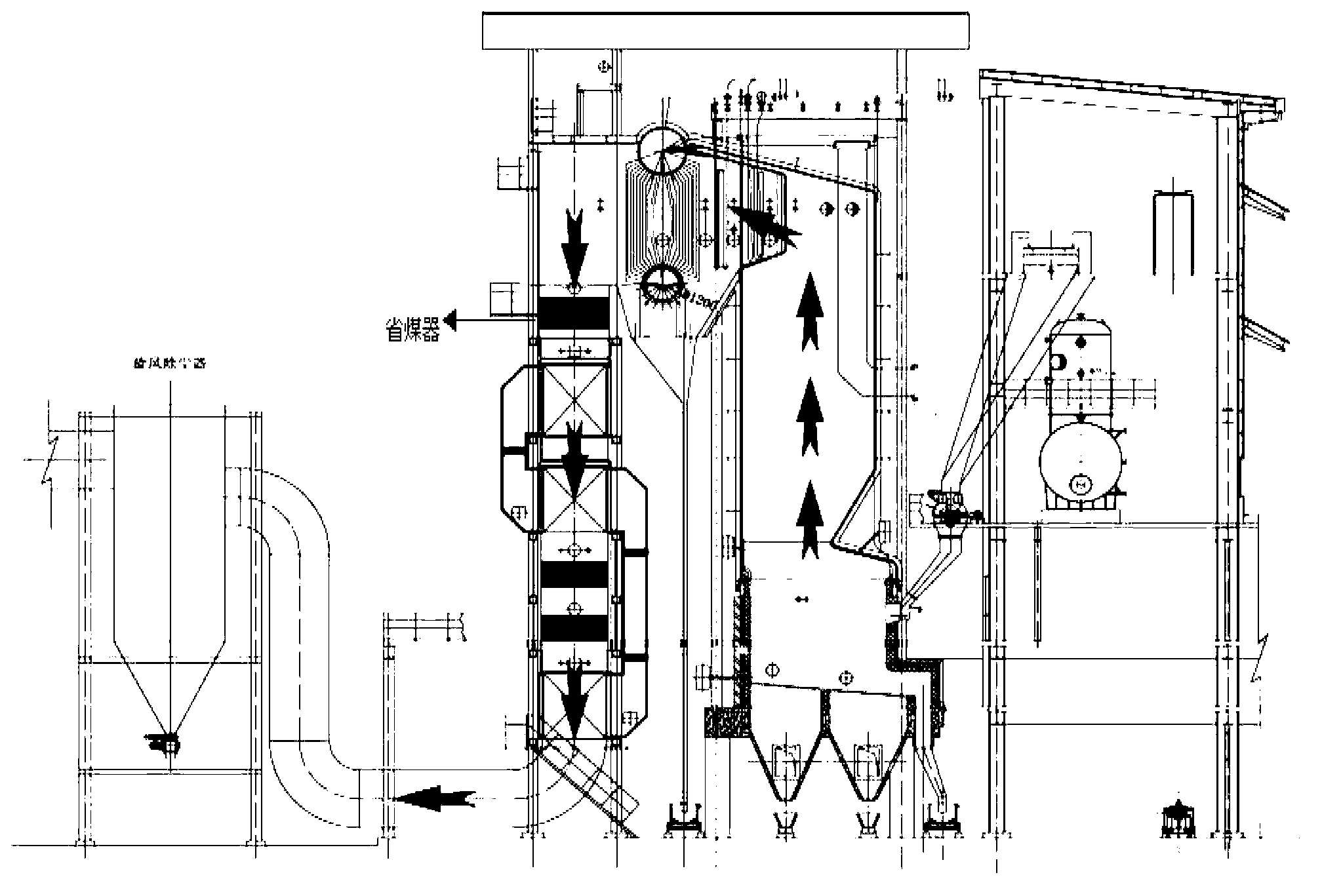

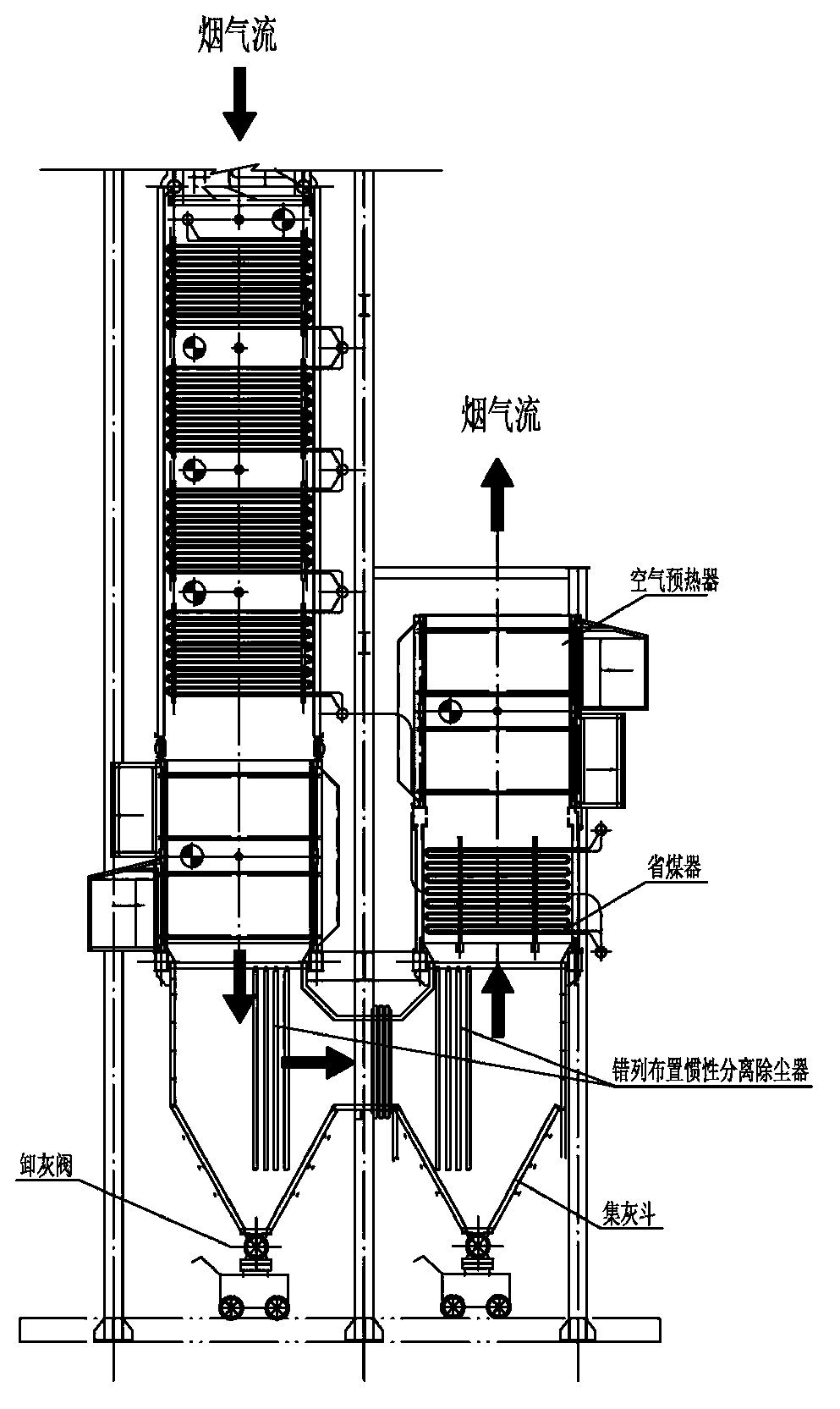

[0029] In order to make the structure, characteristics and advantages of the present invention clearer, prior to the detailed description below in conjunction with specific embodiments, the prior art mentioned in the background art section will be described in conjunction with the accompanying drawings.

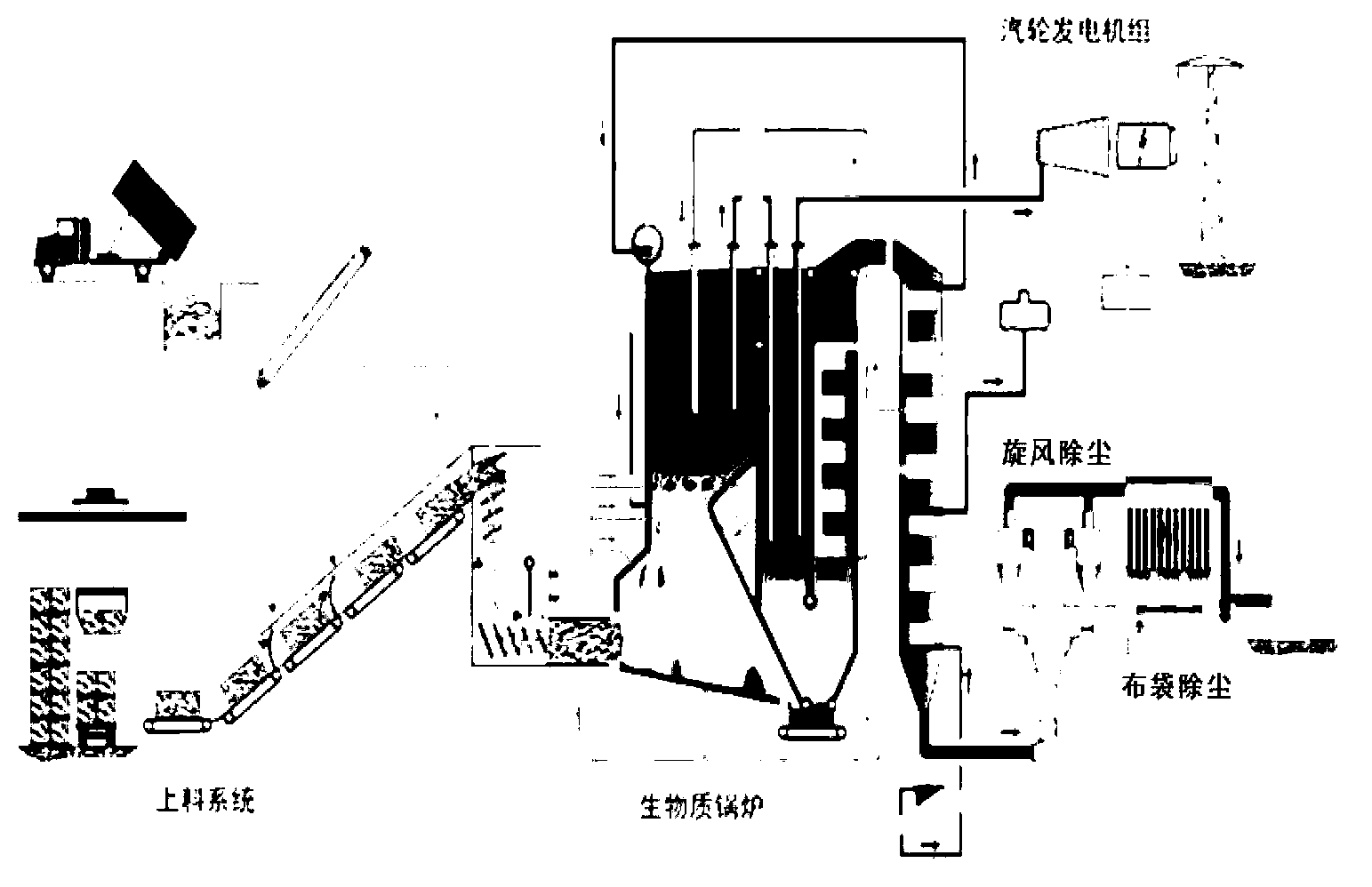

[0030] figure 1 and figure 2 It is respectively a schematic diagram of a common boiler and its dust removal device in the prior art.

[0031] refer to figure 1 Shown is a schematic diagram of a typical layer combustion plus suspension combustion biomass boiler and dust removal system in the prior art. This typical layer combustion plus suspension combustion biomass boiler and dust removal system is generally composed of the feeding system indicated in the figure , a biomass boiler connected to the feeding system, and an external dust removal device, specifically, the external dust removal device includes: cyclone dust collector and bag dust removal equipment. The fuel rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com