Rapid filling mechanism for filling coal mining conveyor

A technology of filling coal mining and conveyors, which is applied in the direction of filling materials, mining equipment, earth cube drilling and mining, etc. It can solve the problems of prolonged mining time, reduced coal mining work efficiency, and difficulty in compacting the compaction mechanism quickly, and achieves a reasonable improvement. High performance, improved filling efficiency, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

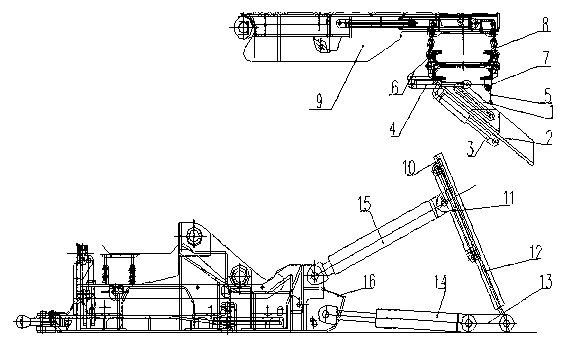

[0010] The fast filling mechanism used for filling the coal mining conveyor in the present invention is mainly composed of an inner tank 1, an outer tank 2, an inclined hydraulic jack 3, a horizontal hydraulic jack 4, a steel wire rope 5, a fixed steel plate 6, a pulley 7, an adjusting push plate 10, and a pushing hydraulic jack. Jack 11, push plate 12, sliding base 13, frame hydraulic jack 14, swing hydraulic jack 15 constitute. It includes a filling coal mining conveyor 8 arranged on the back top beam 9 of the hydraulic support, a hydraulic support base 16, and a material guide mechanism is arranged at the lower part of the filling coal mining conveyor 8, and the material guiding mechanism includes a The fixed steel plate 6 on the outer side of the conveyor 8, and the pulley 7 on the inner side of the filling coal mining conveyor 8, the bottom of the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com