High concrete face rockfill dam seismic strengthening structure and construction method thereof

A technology for face rockfill dam and reinforcement structure, which is applied in fill, dam, barrage, etc., can solve the problems of rusting and aging of steel bars, restricting construction progress, affecting reinforcement effect, etc., so as to improve seismic capacity, ensure construction progress, and avoid The effect of reducing the shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] H=200m, rockfill body 2m, cemented coarse-grained soil material 1m, reinforced steel with a diameter of 4cm.

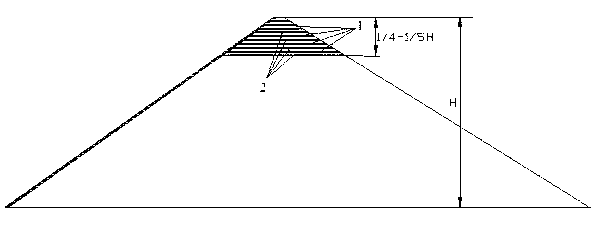

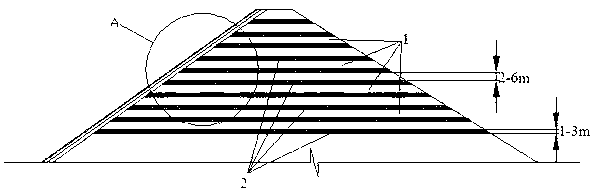

[0020] (a) When the dam body is filled to a height of 40-50m from the dam crest, lay a layer of cemented coarse-grained soil material 2 with a thickness of 1m on the rockfill body 1;

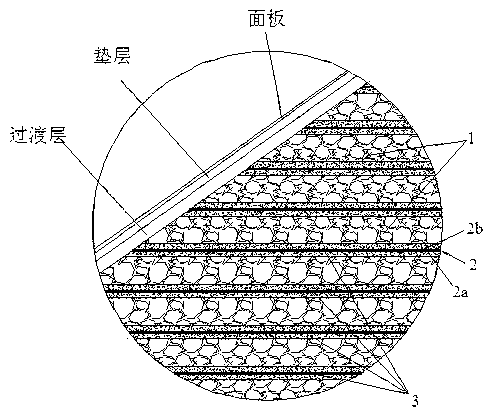

[0021] (b) The laying of each layer of cemented coarse-grained soil material 2 is carried out in two steps. First, the lower layer of cemented coarse-grained soil 2a is laid to run through the upper and lower reaches of the entire dam crest rockfill body, and rolled to a specified density. The thickness after compaction is It is 0.5m; On the lower layer of cemented coarse-grained soil, the steel mesh 3 with a diameter of 4cm is laid. Carry out rolling to the specified density, and the thickness after compaction is 0.5m;

[0022] (c) Fill the dam body rockfill body 1 and carry out layered rolling to the specified density and specified thickness of 2m;

[0023] (d) Repeat steps b...

Embodiment 2

[0025] H=250m, rockfill body 4m, cemented coarse-grained soil material 2m, steel bar with diameter 5cm rebar.

[0026] (a) When the dam body is filled to a height of 50-60m from the dam crest, lay a layer of cemented coarse-grained soil material 2 with a thickness of 2m on the rockfill body 1;

[0027] (b) The laying of each layer of cemented coarse-grained soil material 2 is carried out in two steps. First, the lower layer of cemented coarse-grained soil 2a is laid to run through the upper and lower reaches of the entire dam crest rockfill body, and rolled to a specified density. The thickness after compaction is It is 1.0m; On the lower layer of cemented coarse-grained soil, the steel mesh 3 with a diameter of 5cm is laid. Carry out rolling to the specified density, and the thickness after compaction is 1.0m;

[0028] (c) Fill the rockfill body 1 of the dam body, and carry out layered rolling to the specified density and the specified thickness of 4m;

[0029] (d) Repeat s...

Embodiment 3

[0031] H=300m, the rockfill body is 6m, the cemented coarse-grained soil material is 3m, and the steel bar is rebar with a diameter of 6cm.

[0032] (a) When the dam body is filled to a height of 60-75m from the dam crest, lay a layer of cemented coarse-grained soil material 2 with a thickness of 3m on the rockfill body 1;

[0033] (b) The laying of each layer of cemented coarse-grained soil material 2 is carried out in two steps. First, the lower layer of cemented coarse-grained soil 2a is laid to run through the upper and lower reaches of the entire dam crest rockfill body, and rolled to a specified density. The thickness after compaction is It is 1.5m; On the lower layer of cemented coarse-grained soil, lay a steel mesh 3 with a diameter of 6cm. Carry out rolling to the specified density, and the thickness after compaction is 1.5m;

[0034] (c) Fill the rockfill body 1 of the dam body and carry out layered rolling to the specified density and specified thickness of 6m;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com