Novel environment-friendly high-energy alcohol-based industrial fuel and preparation method thereof

An environmentally friendly and high-energy technology, which is applied in the fuel, petroleum industry, liquid carbon-containing fuel, etc., to achieve the effect of safe storage and transportation, convenient configuration, and prevention of swelling of rubber parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

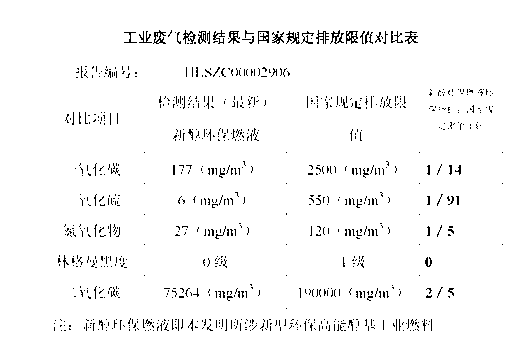

Image

Examples

Embodiment 1

[0018] Take the percentage by weight:

[0019] Methanol: 65% Sugar extraction waste liquid: 8.45%

[0020] Pine perfume: 8% Hydrogen peroxide with a content of 27.5%: 3%

[0021] Xylene: 3% Phytate: 3%

[0022] Benzotriazole: 2% Acetone: 5%

[0023] Ferrocene: 0.05% Lavender oil: 0.5%

[0024] Rubber swelling inhibitor: 2%.

[0025] First inject the fixed weight of methanol into the mixing tank, and then inject the rosin water, hydrogen peroxide, xylene, phytate, benzotriazole, acetone, ferrocene and rubber swelling inhibitor in sequence in proportion, and stand still for 30- After 60 minutes, add sugar extraction waste liquid and lavender oil, stir for about 10-20 minutes, cover, let the mixture stand at room temperature for 2-4 hours, and serve.

Embodiment 2

[0027] Take the percentage by weight:

[0028] Methanol: 70% Sugar extraction waste liquid: 13.39%

[0029] Pine perfume: 7% Hydrogen peroxide with a content of 27.5%: 1%

[0030] Xylene: 1.5% Phytate: 1%

[0031] Benzotriazole: 1.5% Acetone: 3%

[0032] Ferrocene: 0.01% Lavender oil: 0.1%

[0033] Rubber swelling inhibitor: 1.5%.

[0034] First inject the fixed weight of methanol into the mixing tank, and then inject the rosin water, hydrogen peroxide, xylene, phytate, benzotriazole, acetone, ferrocene and rubber swelling inhibitor in sequence in proportion, and stand still for 30- After 60 minutes, add sugar extraction waste liquid and lavender oil, stir for about 10-20 minutes, cover, let the mixture stand at room temperature for 2-4 hours, and serve.

Embodiment 3

[0036] Take the percentage by weight:

[0037] Methanol: 66.45% Sugar extraction waste liquid: 10%

[0038] Pine perfume: 5% Hydrogen peroxide with a content of 27.5%: 3%

[0039] Xylene: 3% Phytate: 3%

[0040] Benzotriazole: 2% Acetone: 5%

[0041] Ferrocene: 0.05% Lavender oil: 0.5%

[0042] Rubber swelling inhibitor: 2%.

[0043] First inject the fixed weight of methanol into the mixing tank, and then inject the rosin water, hydrogen peroxide, xylene, phytate, benzotriazole, acetone, ferrocene and rubber swelling inhibitor in sequence in proportion, and stand still for 30- After 60 minutes, add sugar extraction waste liquid and lavender oil, stir for about 10-20 minutes, cover, let the mixture stand at room temperature for 2-4 hours, and serve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com