Thixotropic slurry anti-drag material for pipe jacking and preparation method thereof

A thixotropic mud, effective technology, applied in the field of concrete materials, can solve problems such as polluting the environment, affecting traffic, and high project cost, achieving broad application prospects and reducing jacking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

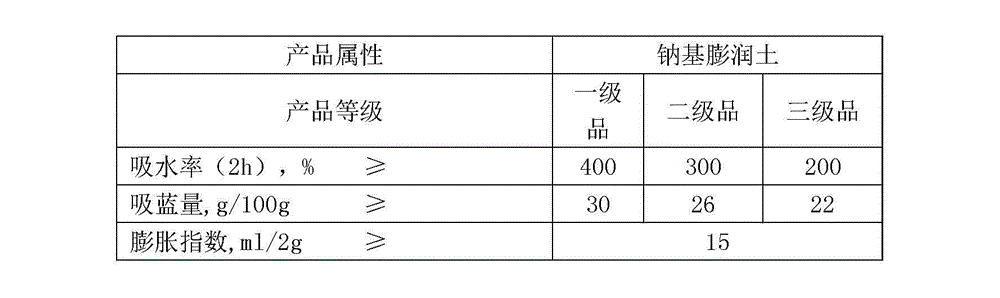

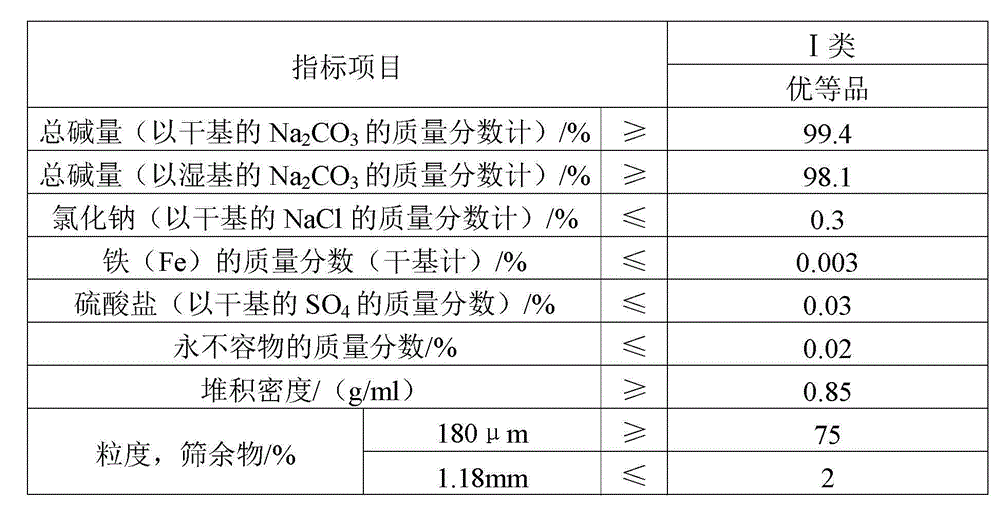

[0017] The bentonite described in the present invention is a third-class product of sodium bentonite, the pH of water is 7, and the degree of substitution of CMC is 0.9. Experiments have found that the degree of substitution has little influence on the effect of frictional resistance; soda ash is Class I.

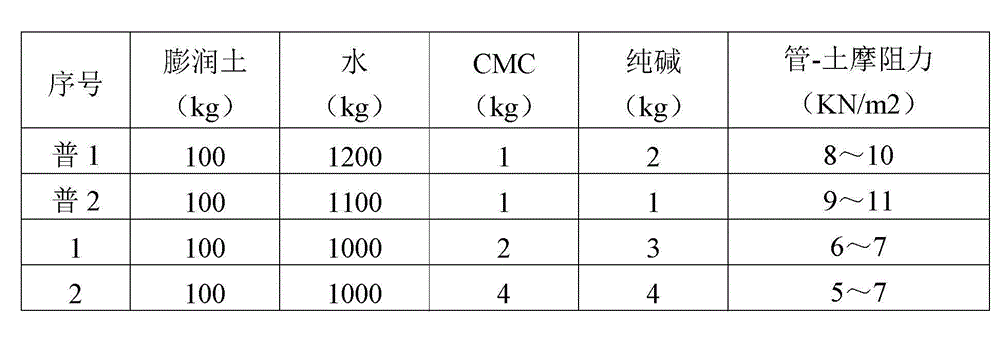

[0018] The present invention will be specifically described below in conjunction with the examples, but the present invention is not limited to the following examples. The present invention provides 2 embodiments, respectively numbered 1-2, and their matching ratios and measured frictional resistance are shown in Table 1. In order to illustrate the effect, 2 comparisons of ordinary mud ratios are listed, numbered respectively as Pu 1-2.

[0019] The pipe-soil friction resistance is measured by the on-site pre-embedded steel bar stress gauge.

[0020] Table 1 Proportion of thixotropic mud

[0021]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com