Slurry balance pipe jacking construction method

A mud-water balance and construction method technology, applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as poor results, and achieve the effect of reducing jacking force and friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

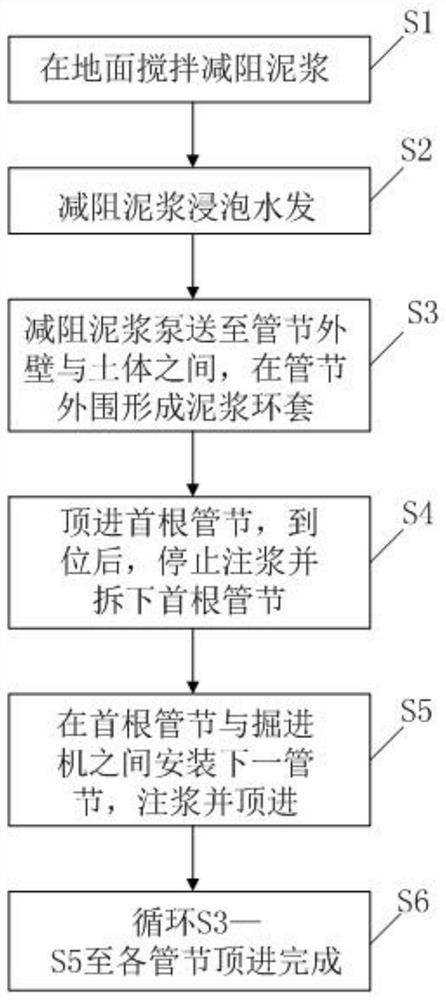

[0032] This embodiment provides a mud-water balance pipe jacking construction method, and the mud-water balance pipe jacking includes a plurality of pipe joints, such as figure 1 As shown, the method includes the following steps:

[0033] S1: Stir the drag reducing mud on the ground; the drag reducing mud includes bentonite, soda ash, sodium carboxymethylcellulose and water, bentonite is 17% by weight, soda ash is 1% by weight, sodium carboxymethylcellulose is 0.3% by weight, and water is wt81.7%;

[0034] S2: Soak water in drag-reducing mud;

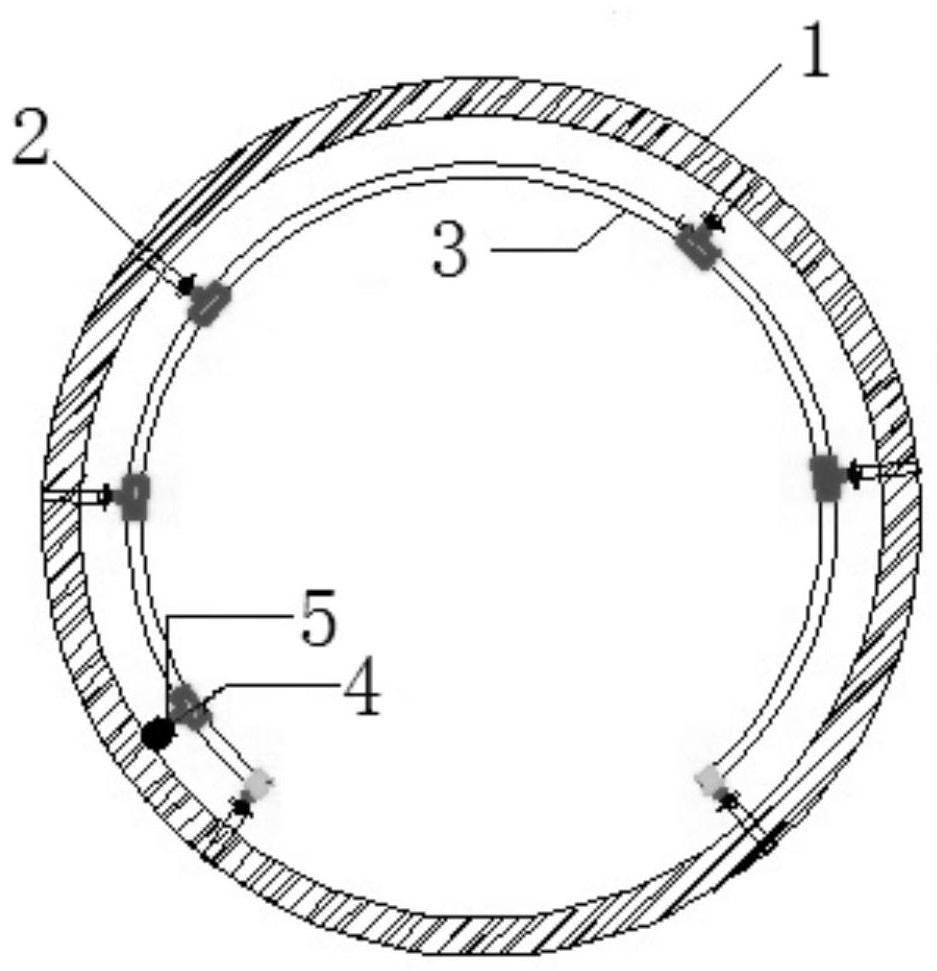

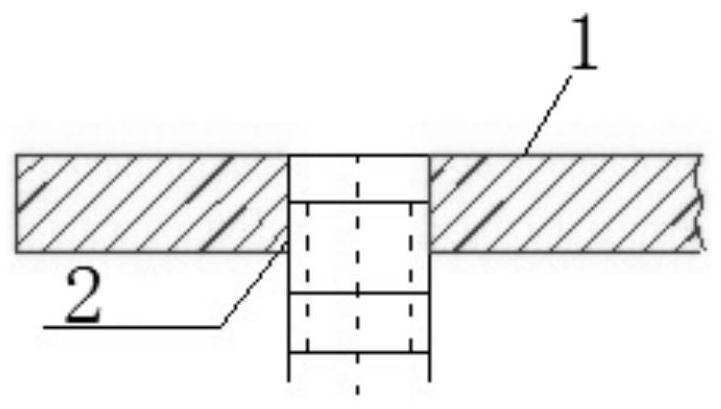

[0035] S3: The drag reducing mud is pumped between the outer wall of the pipe joint 1 and the soil, and a mud ring is formed around the pipe joint 1;

[0036] S4: The first pipe section 1 is jacked in, and when it is in place, stop grouting and remove the first pipe section 1;

[0037] S5: install the next pipe section 1 between the first pipe section 1 and the roadheader, inject grout and jacking;

[0038] S6: Cycle S3-S5 until the...

Embodiment 2

[0046] This embodiment provides a mud-water balance pipe jacking construction method. The difference from Embodiment 1 is that bentonite is wt13%, soda ash is wt0.5%, sodium carboxymethylcellulose is wt0.1%, and water is wt86. 4%.

Embodiment 3

[0048]This embodiment provides a mud-water balance pipe jacking construction method. The difference from Embodiment 1 and Embodiment 2 is that bentonite is wt15%, soda ash is wt0.8%, and sodium carboxymethylcellulose is wt0.2%. Water is wt84%.

[0049] The following table has provided the relationship between the slurry proportioning and the coefficient of friction in Embodiment 1, Embodiment 2, Embodiment 3 and other situations, as can be seen from it, bentonite is 13wt%-17wt%, and soda ash is 0.5wt%- 1 wt%, sodium carboxymethyl cellulose 0.1 wt%-0.3 wt%, and the balance being water, the drag reduction effect is better.

[0050] Serum ratio

[0051]

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com