Fiberglass pipe sealing sleeve joint and its processing method

A technology of pipe sealing and FRP, which is applied in the direction of pipes/pipe joints/fittings, passing components, mechanical equipment, etc., which can solve the problems of unsuitable ordinary FRP pipes, easy to pull and loose in the axial direction, and easy to pull and loose, so as to achieve construction Simple and convenient, reduce jacking resistance, reliable connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

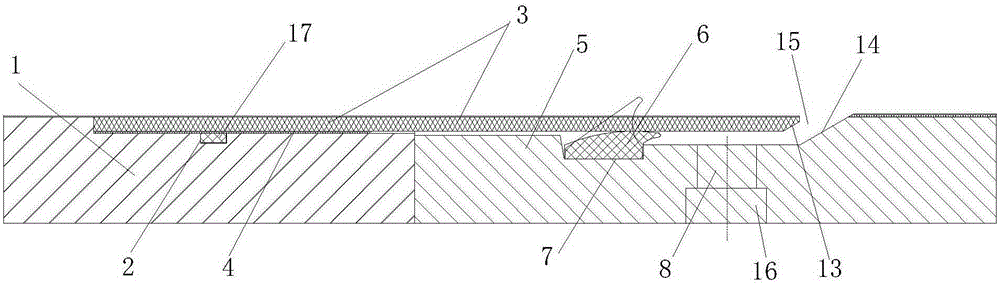

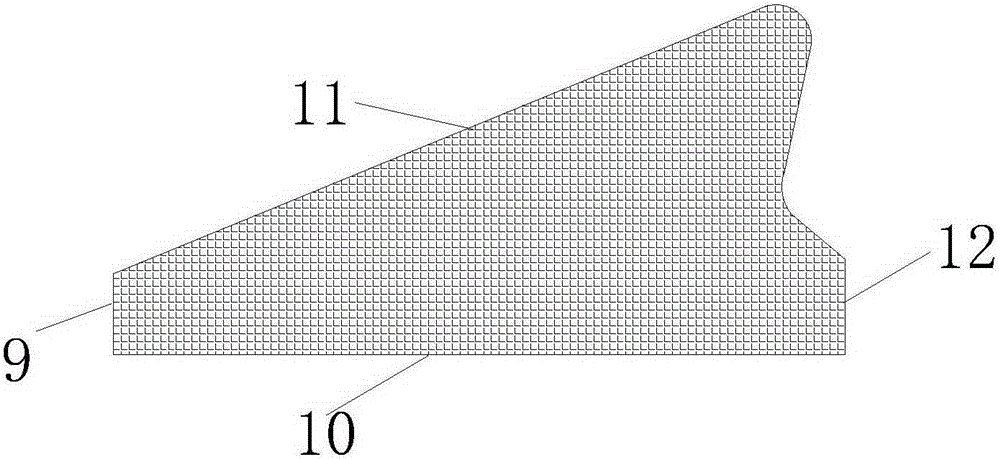

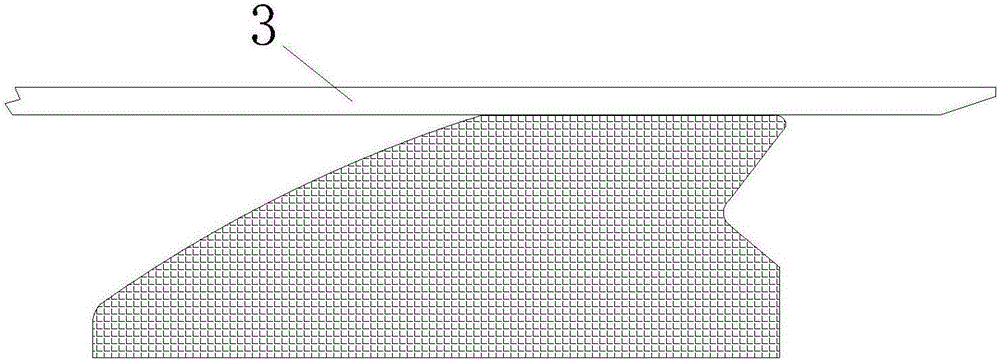

[0025] This embodiment provides a sealing collar interface for FRP pipes, which is used to connect FRP pipes on the left and right sides, wherein the connection end of the FRP pipe on one side is a socket end, and the connection end of the FRP pipe on the other side is a socket end, and the connection end of the FRP pipe on the other side is a socket end. The outer wall of the pipe is concaved to form the socket inner ring 1, the outer diameter of the socket inner ring is smaller than the outer diameter of the FRP pipe, and an annular groove 2 is provided in the middle of the socket inner ring 1 to accommodate the water-expandable rubber ring 17, and the socket inner ring 1 is covered The stainless steel collar 3 is installed, and the inner ring of the socket and the stainless steel collar are bonded together through the bonding layer 4; the outer wall of the pipe at the socket end is concave to form the inner ring 5 of the socket, and the outer diameter of the inner ring of the...

Embodiment 2

[0039] The present embodiment is basically the same as Example 1, the difference is that the adhesive layer is formed by curing the adhesive, and the adhesive is made of 38 parts of unsaturated polyester resin by each raw material, 1.2 parts of curing agent, and 1.2 parts of accelerator. 59.6 parts of glass fiber powder is evenly prepared by stirring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com