Large diameter jacking pipe resistance reduction construction method under miscellaneous filling soil geology condition

A construction method and geotechnical technology, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems that the mud lubricating film cannot be formed and is difficult to achieve, so as to ensure the construction quality and construction safety , speed up the construction period, reduce the effect of frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

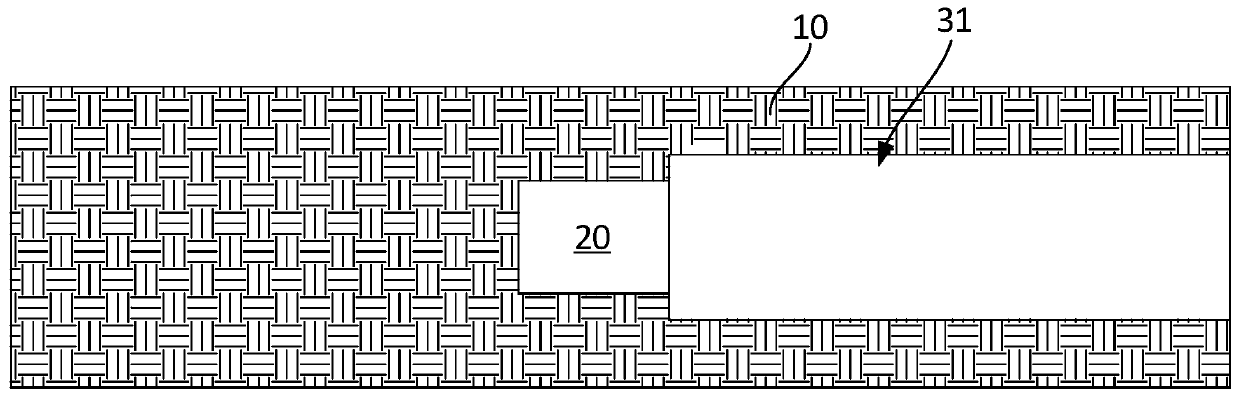

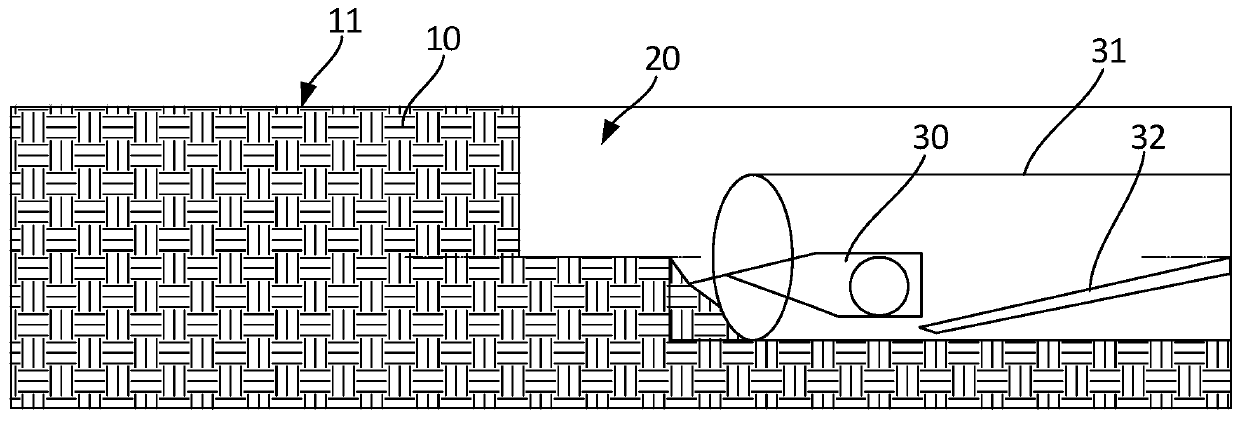

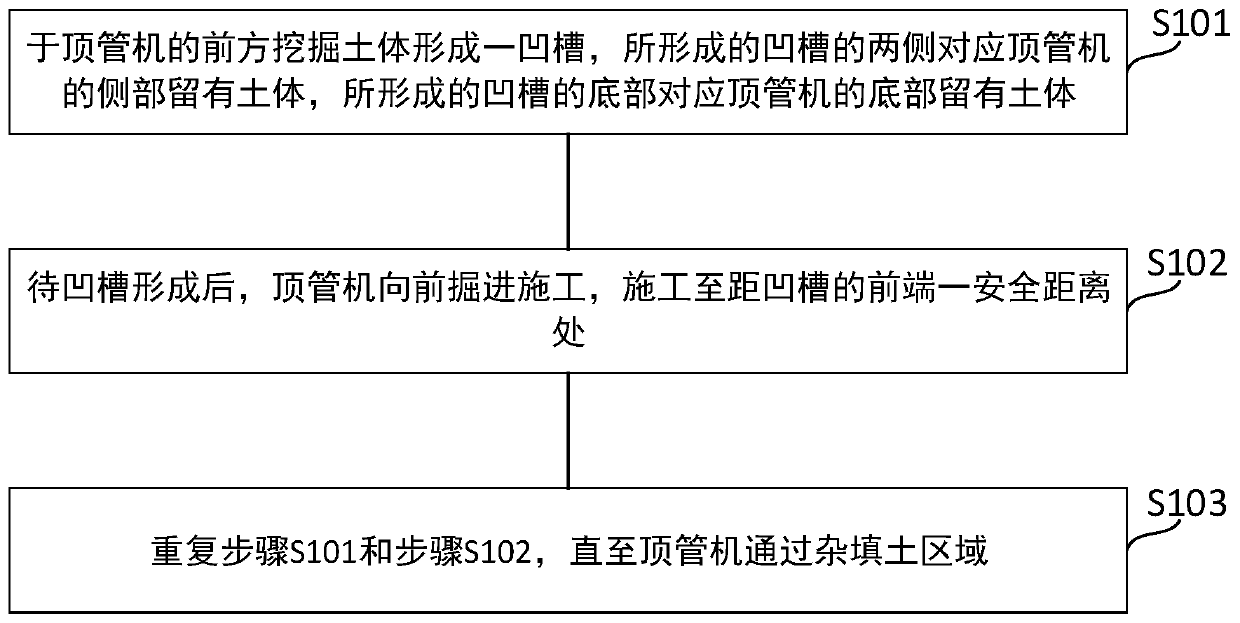

[0021] refer to image 3 , The present invention provides a large-diameter pipe jacking drag reduction construction method under the condition of miscellaneous fill land, which is used to solve the problem that the existing methods of waxing and grouting to reduce friction are not applicable to the miscellaneous fill land geological environment. The construction method of the present invention is used to reduce the frictional resistance of the pipe jacking machine in the miscellaneous filling area. The pipe jacking construction is carried out in the way of slotting first and then jacking. The groove formed by excavation reduces the jacking resistance of the pipe jacking machine, which can reduce the jacking resistance of the pipe jacking machine by more than half. Because the pre-grooving takes away part of the soil, it destroys the miscellaneo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com