Vacuum infusion process for forming composite material and composite material

A technology of vacuum introduction and composite materials, which is applied in the field of composite material forming technology, can solve the problems of reducing the strength of composite materials, affecting the mechanical properties and apparent quality of composite materials, and achieving the reduction of porosity, improvement of apparent quality and mechanical properties, The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

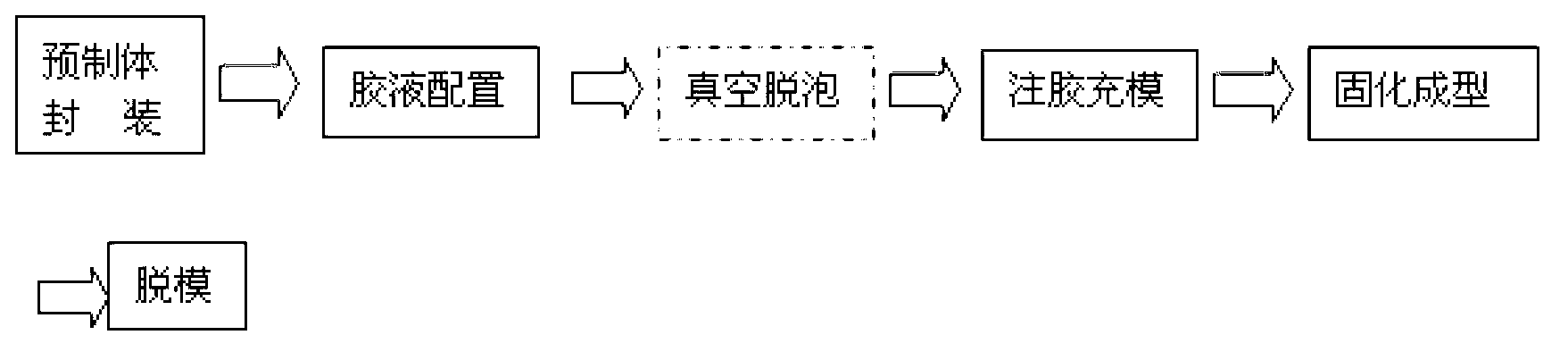

[0021] Such as figure 1 As shown, this embodiment provides a vacuum introduction process for composite material forming including:

[0022] (1) Preform packaging

[0023] Reinforcement material (fiberglass, carbon fiber, sandwich material, etc.) is laid on the mold and sealed with a vacuum bag.

[0024] (2) Glue configuration

[0025] According to the actual ratio of the original factory formula of the resin, the main component is a mixture of 191 unsaturated resin and 191 unsaturated resin curing agent (generally methyl ethyl ketone peroxide MEKP is used). The 191 unsaturated resin mixture is the raw material for preparing composite materials.

[0026] (3) Vacuum defoaming

[0027] Put the container (such as a beaker) containing the 191 unsaturated resin mixture into a vacuum drying oven, and perform vacuum degassing treatment on the 191 unsaturated resin mixture, control the vacuum degree in the vacuum drying oven to -0.02MPa, and vacuumize The time is 1 minute, and the ...

Embodiment 2

[0038] This embodiment provides a vacuum introduction process for forming composite materials, including:

[0039] (1) Preform packaging

[0040] Reinforcement material (fiberglass, carbon fiber, sandwich material, etc.) is laid on the mold and sealed with a vacuum bag.

[0041] (2) Glue configuration

[0042] According to the actual ratio of the original factory formula of the resin, the main component is a mixture of Altac430LV vinyl resin (pre-accelerated type) and Altac430LV vinyl resin curing agent (generally using methyl ethyl ketone peroxide MEKP). The raw material of the material.

[0043] (3) Vacuum defoaming

[0044] Put the container (such as a beaker) containing the Altac430LV vinyl resin mixture into a vacuum drying oven, and perform vacuum degassing treatment on the Altac430LV vinyl resin mixture, control the vacuum degree in the vacuum drying oven to 0.05MPa, and vacuumize the The time is 2 minutes, and the Altac430LV vinyl resin mixture after the vacuum def...

Embodiment 3

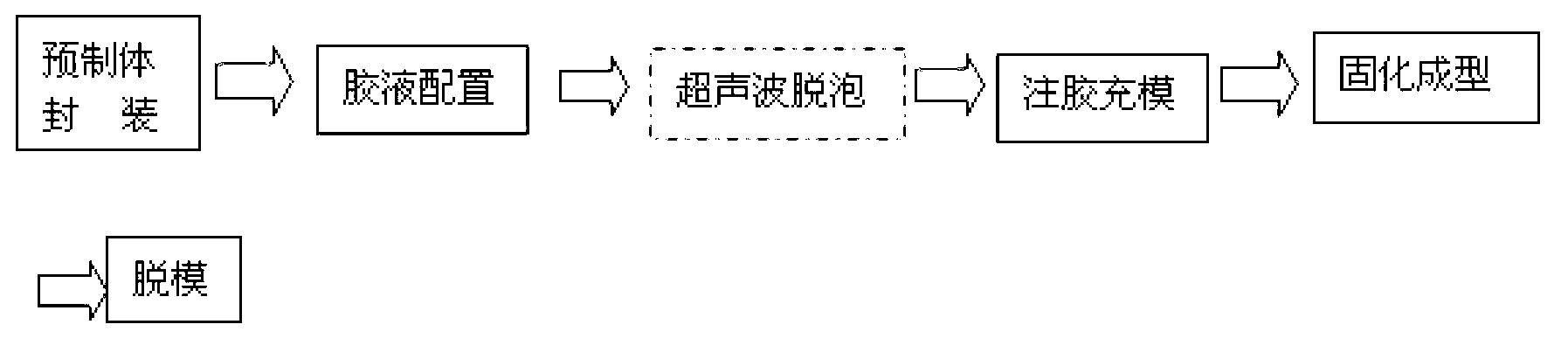

[0053] This embodiment provides a vacuum introduction process for forming composite materials, including:

[0054] (1) Preform packaging

[0055] Reinforcement material (fiberglass, carbon fiber, sandwich material, etc.) is laid on the mold and sealed with a vacuum bag.

[0056] (2) Glue configuration

[0057] The main component is a mixture of Derakane411 vinyl resin and Derakane411 vinyl resin curing agent (generally methyl ethyl ketone peroxide MEKP) according to the actual ratio of the original factory formula of the resin. The mixture of Derakane411 vinyl resin is the raw material for the preparation of composite materials.

[0058] (3) Vacuum defoaming

[0059] Put the container (such as a beaker) containing the Derakane411 vinyl resin mixture into a vacuum drying oven, and perform vacuum degassing treatment on the Derakane411 vinyl resin mixture, and control the vacuum degree in the vacuum drying oven to 0.02MPa. The time is 0.5 minutes, and the Derakane411 vinyl resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com