Ceramic medium-and-low pressure slip-casting device

A grouting molding and low-pressure technology, which is applied in the field of sanitary ware ceramic processing and production, can solve the problems of inconvenient mobilization of moulds, high recruitment and labor costs, and high production costs, so as to protect workers' health, facilitate maintenance and disassembly, and reduce labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

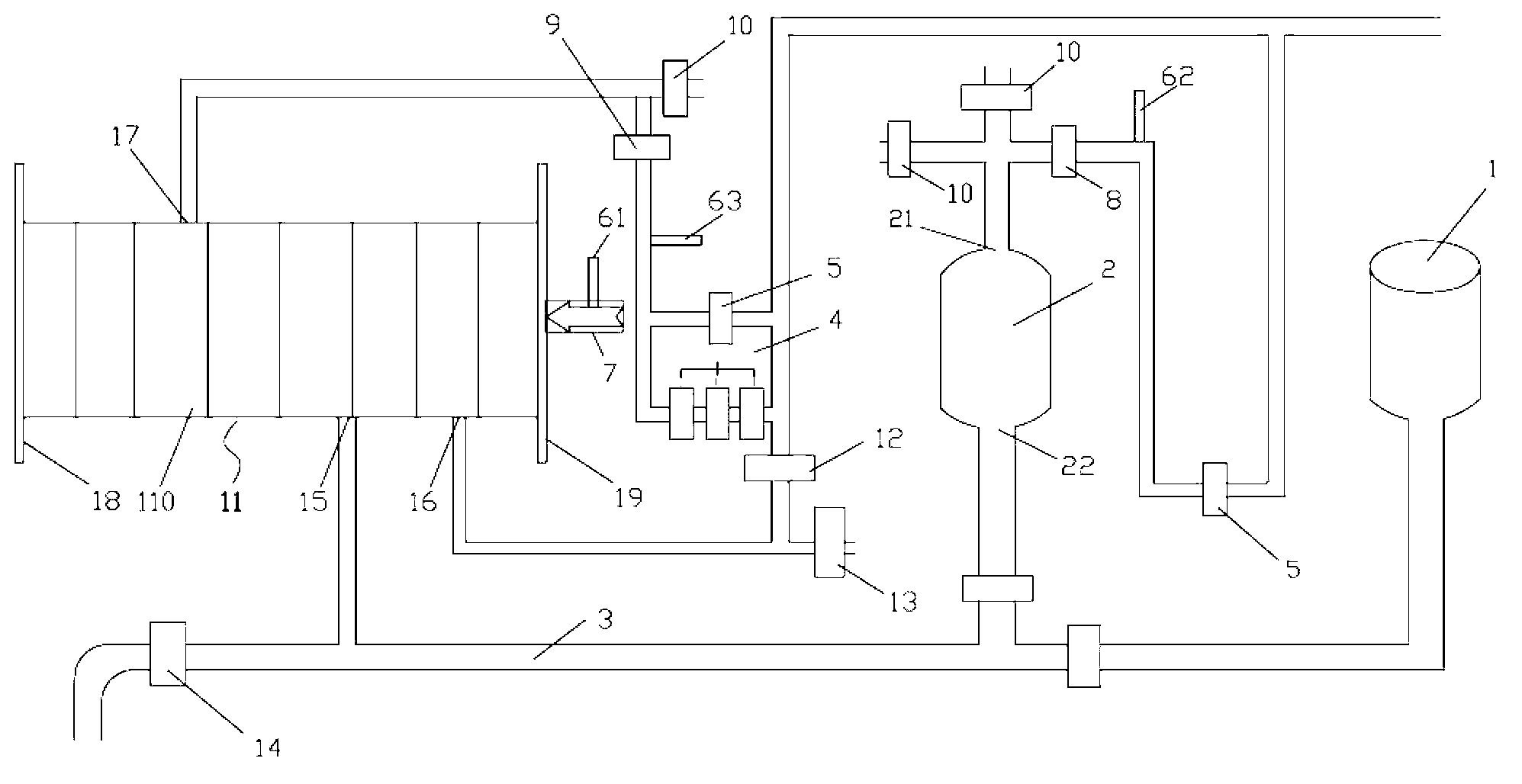

[0020] Referring to the accompanying drawings and specific embodiments below, the present invention will be further described:

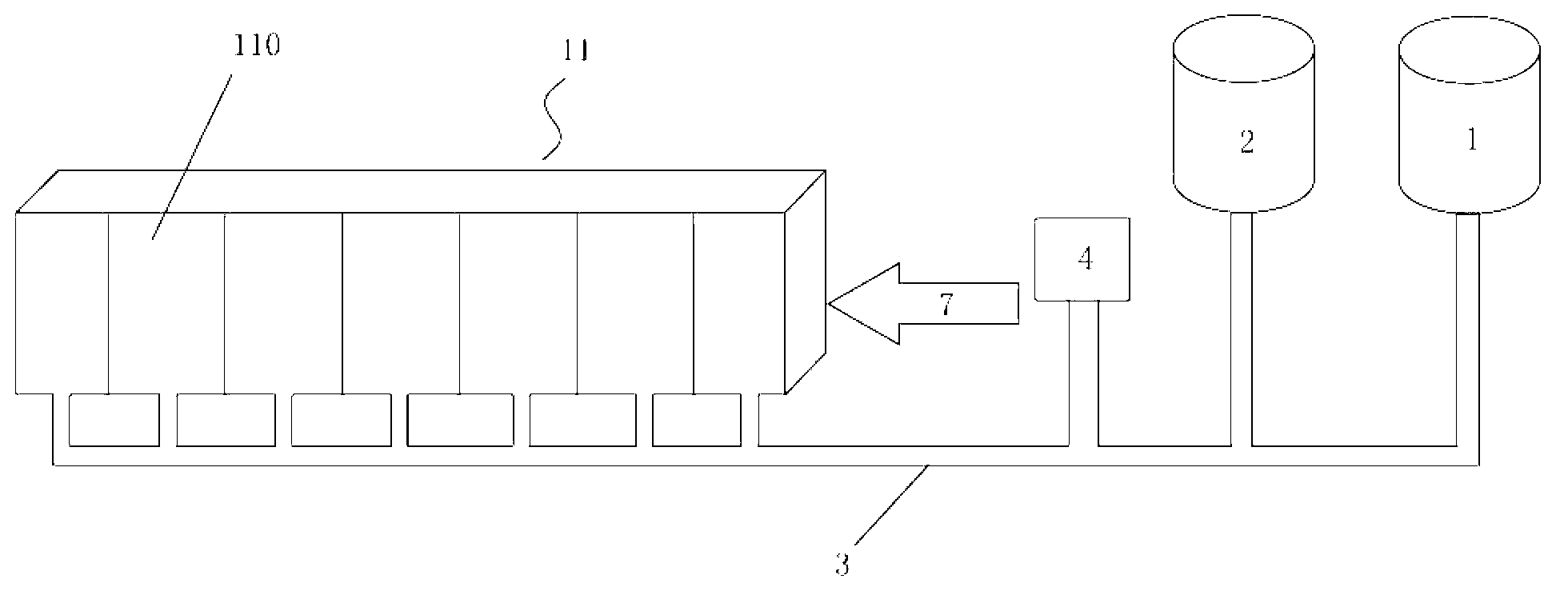

[0021] see figure 1 , the medium and low-pressure grouting molding device for ceramics according to the present invention includes an atmospheric pressure slurry cylinder 1, a pressurized slurry cylinder 2 and a mold group 11 connected in sequence by a slurry delivery pipe 3, and also includes a control unit 4 for compacting The propulsion unit 7 of the mold set 11, the first pressure sensor 61 for detecting the internal pressure of the mold set 11 and the execution unit 5 for issuing instructions to the control unit 4, the execution unit 5 and the first pressure sensor 61 are connected with the control unit 4, and the propulsion unit 7 is connected with the execution unit 5.

[0022] In this embodiment, the pressurized pulp cylinder 2 is provided with an air pressure port 21 and a slurry pressurized port 22, and an exhaust valve group and a pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com