HFSi welding pin and preparation method thereof

A welding pin, stirring and mixing technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inability to solve the technical difficulties of PFA tube sheet welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

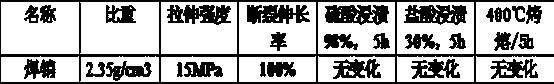

[0016] The HFSi welding pin is formed by pressing and sintering after mixing three raw materials, and the three raw materials and their weight percentages are: 70% fluororesin powder, 20% polyphenylene ester and 10% ceramic powder.

[0017] The present invention will be described in further detail below.

[0018] 1. Key technology of HFSi welding pin

[0019] HFSi welding pins are used in the production process of PFA heat exchangers. When the end plate of the heat exchanger is put into the welding fixture, the two ends of the tubes pass through the orifice plate respectively, and the protruding part and the end plate are repaired and inserted into the hole. Welding pins, using the expansion of the welding pins at high temperature and the resultant force of swelling caused by the thermal expansion of the end plate, extrude the molten orifice plate and the tube wall to achieve the purpose of welding. After cooling and shaping, pull out the welding pin, the aperture of each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com