Method for reducing difference on two sides of paper-making reconstituted tobacco

A technology of reconstituted tobacco leaf and papermaking method, which is applied in the fields of tobacco, tobacco preparation, application, etc., and can solve the problems that there are no literature or patent reports on reducing or eliminating the two-sided difference of reconstituted tobacco leaf products, so as to eliminate the two-sided difference phenomenon, reduce the coating Cloth amount and coating amount are close to each other

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the implementation of technical scheme is described in further detail:

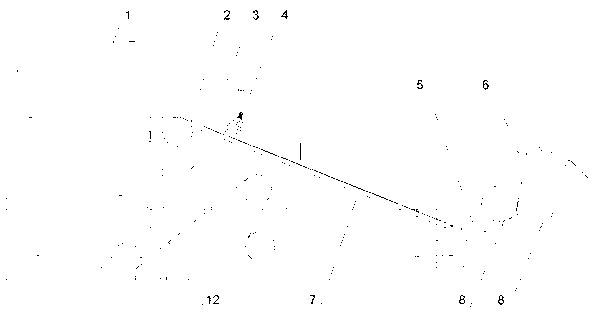

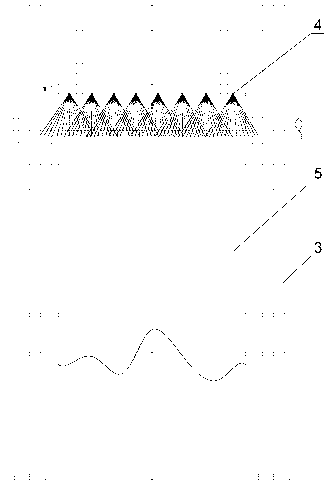

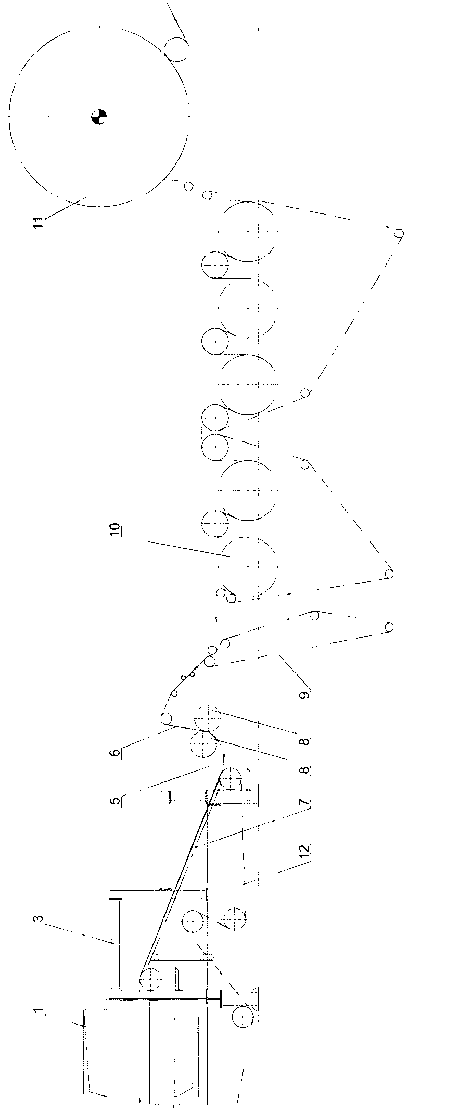

[0014] like figure 1 As shown, the existing dip coating coating method is to pass the substrate 6 with a dryness of about 75% through a pair of counter-rotating rubber rollers 8, and there is a coating liquid (dip 6) with a height of ~200mm between the roller surfaces at the passing place. Paste) is impregnated on the substrate 6. After coating, the sheet 5 goes up to the set height along the inclined surface and then enters the drying box 1 horizontally for drying. Since the substrate 6 adopts a strong drying method on the large cylinder 11, and the small cylinder 10 The role of the film is limited to state adjustment, not beneficial to eliminate the poor smoothness of both sides, so the front and back of the substrate 6 has poor smoothness before coating, although after coating, the sheet 5 is guided upward by the copper mesh 12 from the fixed-lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com