Printed circuit board press-in connection-type rectangular connector

A rectangular connector and press-fit connection technology, which is applied in the direction of connection, fixed connection, and parts of the connection device, can solve the problems of small high-precision integrated equipment, inconvenient operation for personnel, and limited installation space, so as to save installation space , the signal of each channel is unified, and the effect of reliable contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The invention provides a rectangular electrical connector that is press-fitted with a printed board, thereby changing the dip-soldering connection between the original connector and the printed board to an interference-fit crimping type between the contact piece and the printed board, not only The contact is reliable, the installation space is saved, and the installation and removal tools designed by itself are used to save time and effort. It solves the cumbersome process of dip-soldering common printed board connectors, and the operation is very convenient. It is very suitable for stacked installation and use of printed boards, so that the signals of each circuit between printed boards of each layer can be unified and integrated management.

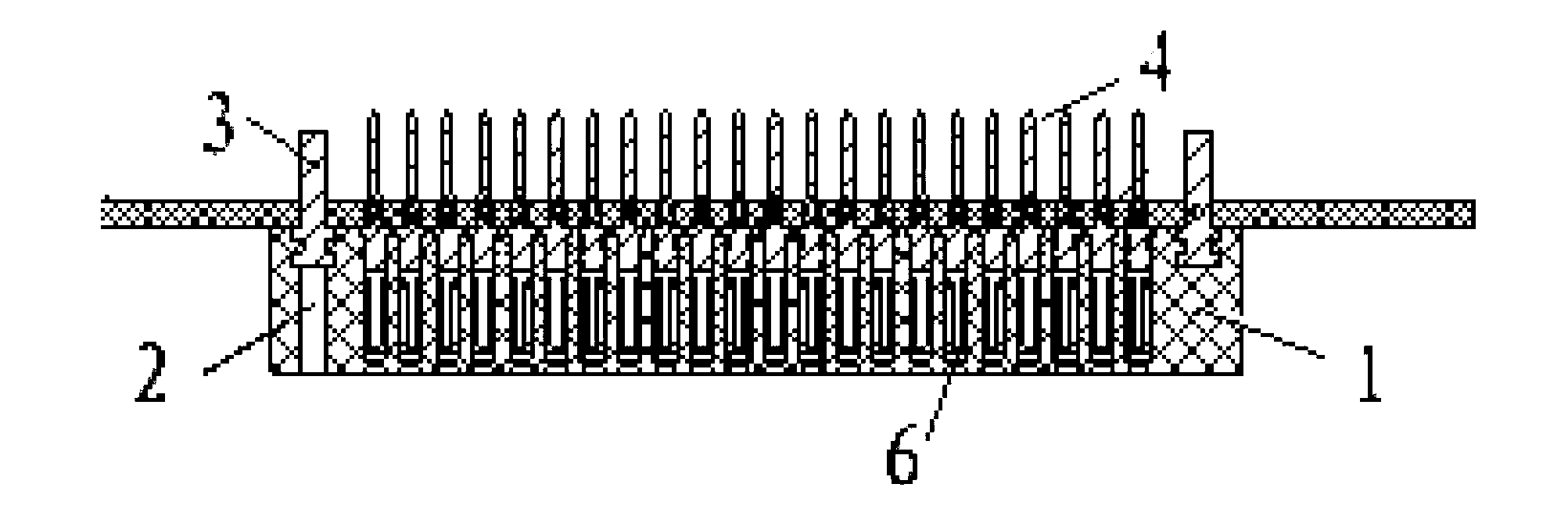

[0027] A rectangular connector for press-fit connection to a printed board, comprising an insulator 1, guide sleeves 2 / or guide pins 3 for positioning and connecting to each other are arranged on both sides of the insulator 1, and...

Embodiment 2

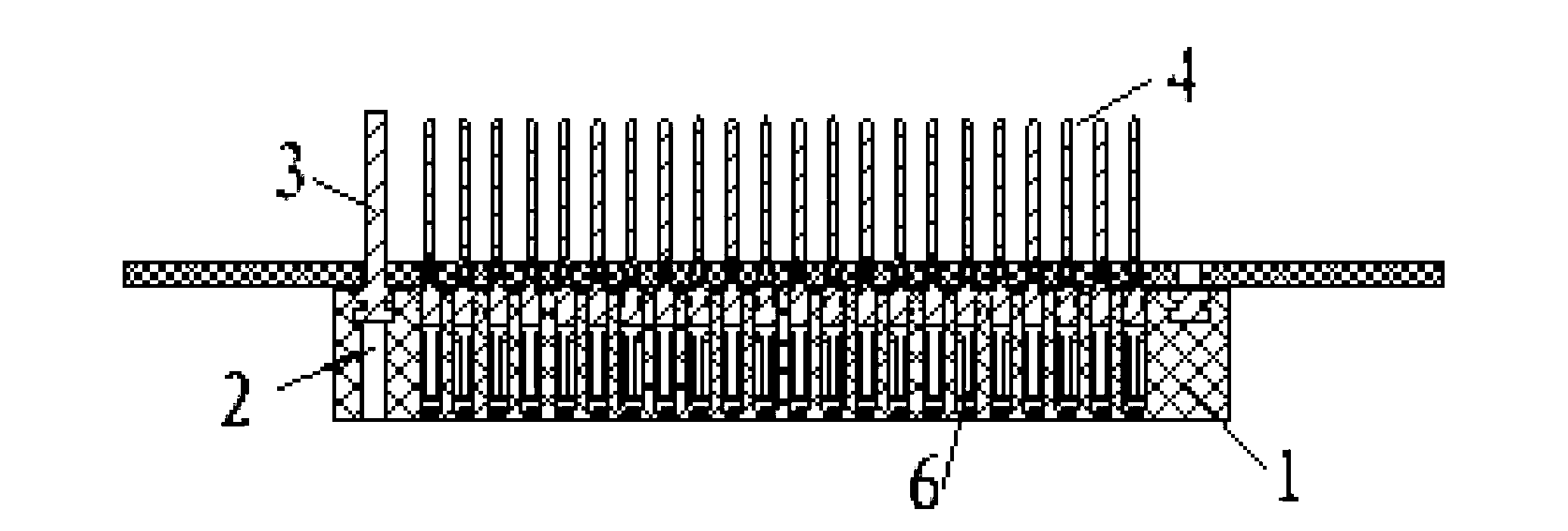

[0039] This embodiment is basically the same as Embodiment 1, the difference is:

[0040] See attached figure 2 : One side of the insulator 1 is provided with a jack 4, and the other side is provided with a slot 6, and this structure is called a press-in socket. The design of jack length can be long or short according to actual needs. figure 2 It is a long-hole press-fit socket.

Embodiment 3

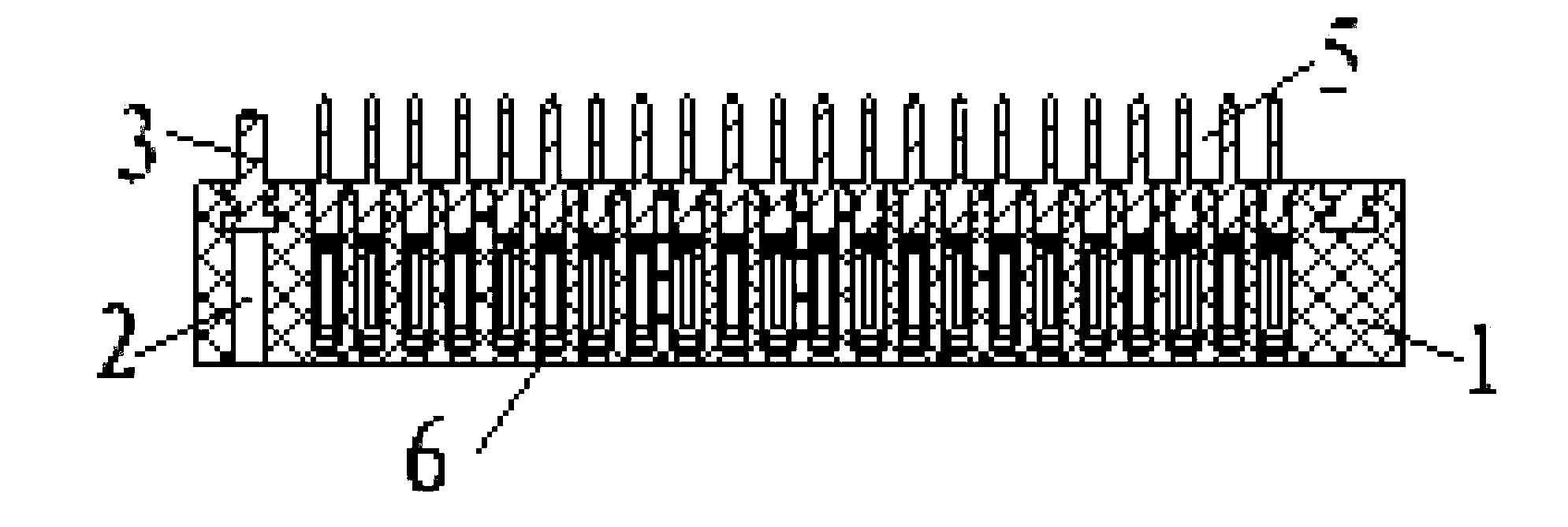

[0042] This embodiment is basically the same as Embodiment 1, the difference is:

[0043] See attached image 3 : One side of the insulator 1 is provided with a pin 5, and the other side is provided with a slot 6, and this structure is called a straight socket. The straight socket mainly plays a connection role.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com