Beam bridge damage assessment early-warning method and early-warning system based on crack development height

A technology of crack height and crack development, applied in the direction of strength characteristics, using stable bending force to test the strength of materials, measuring devices, etc. problems, to achieve the effect of intuitive monitoring content, accurate detection results, and prevention of vicious accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The girder bridge of this embodiment is: a certain bridge on National Highway 309, which was opened to traffic in 1975. The total length of the bridge is 160 meters. The diameter is 20 meters, the calculated span is 19.60 meters, and the total length of the main beam is 20 meters.

[0068] After visual inspection, it is found that the main girder defects are mainly manifested as: the web concrete cracks of the main girder, and the distribution of cracks in the beams of the whole bridge is similar. The 1 / 4 span area from the beam end is dominated by oblique cracks, and 8 The span section is dominated by reticular cracks, and the mid-span area is dominated by vertical cracks with a high distribution density, generally extending to 1 / 2 the beam height, and the mid-span cracks extend to the upper edge of the web, and the highest three cracks are evenly distributed. 1.1 meters high.

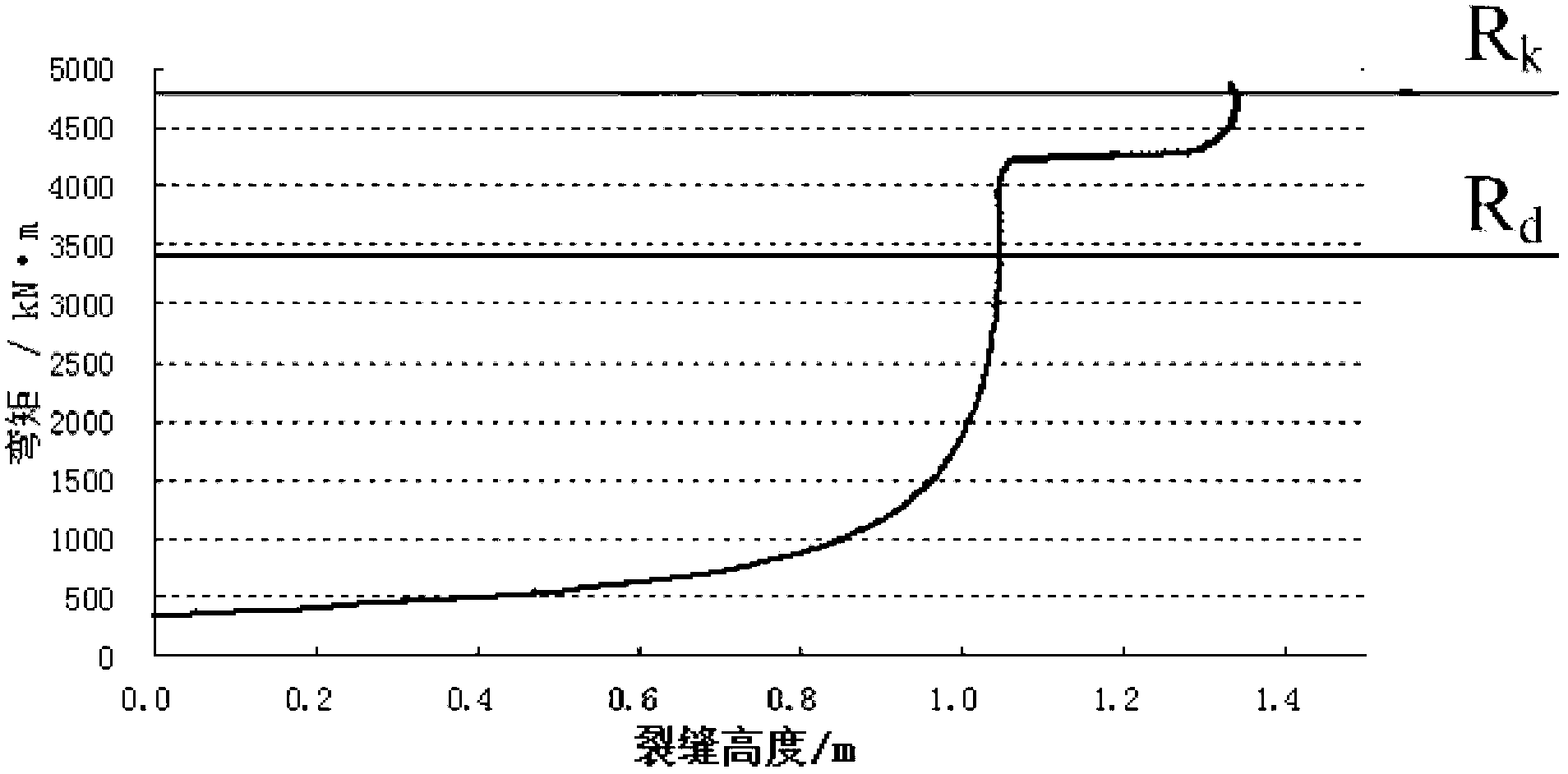

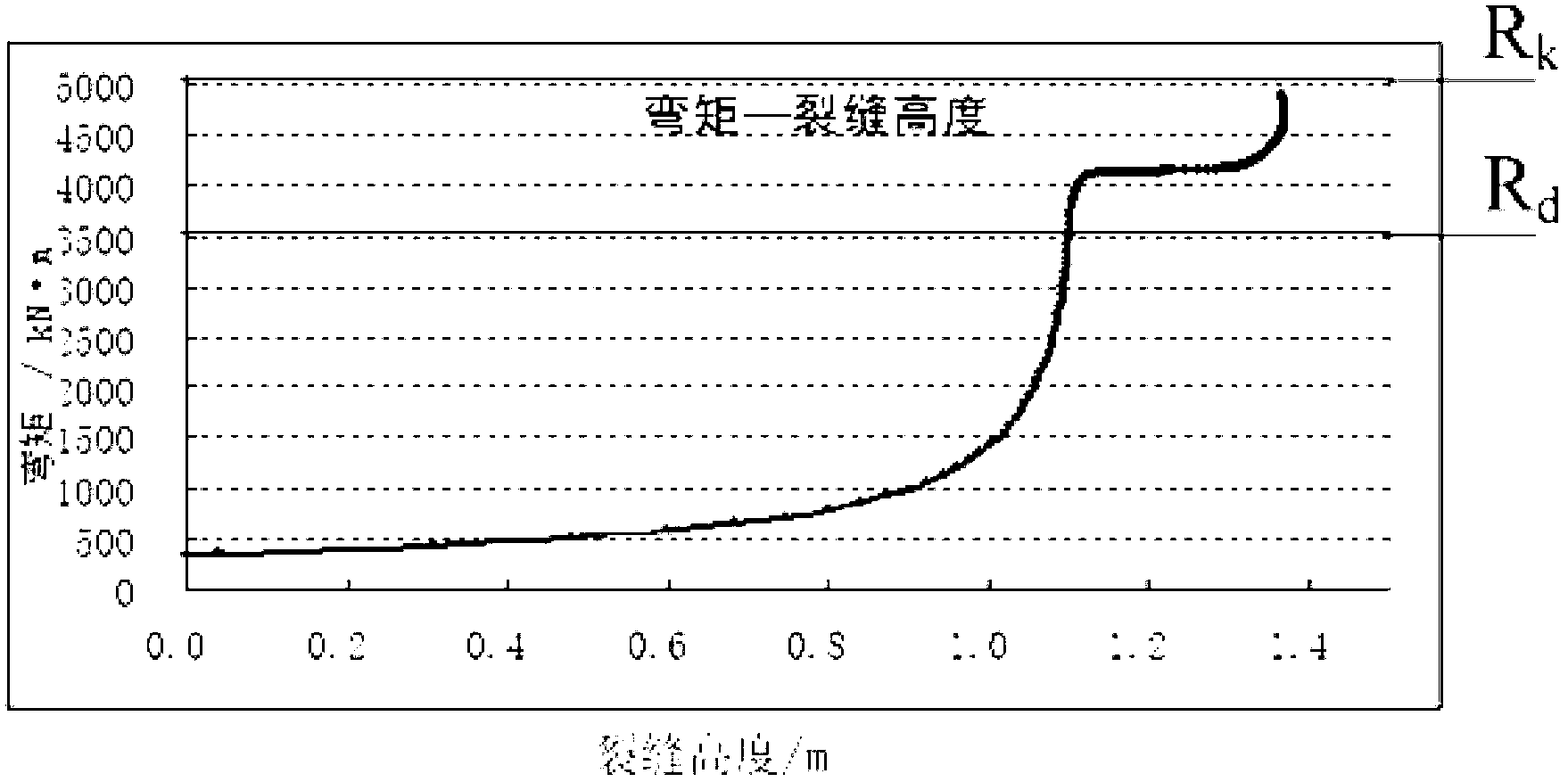

[0069] The relationship between bending moment and crack height of the middle girder of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com